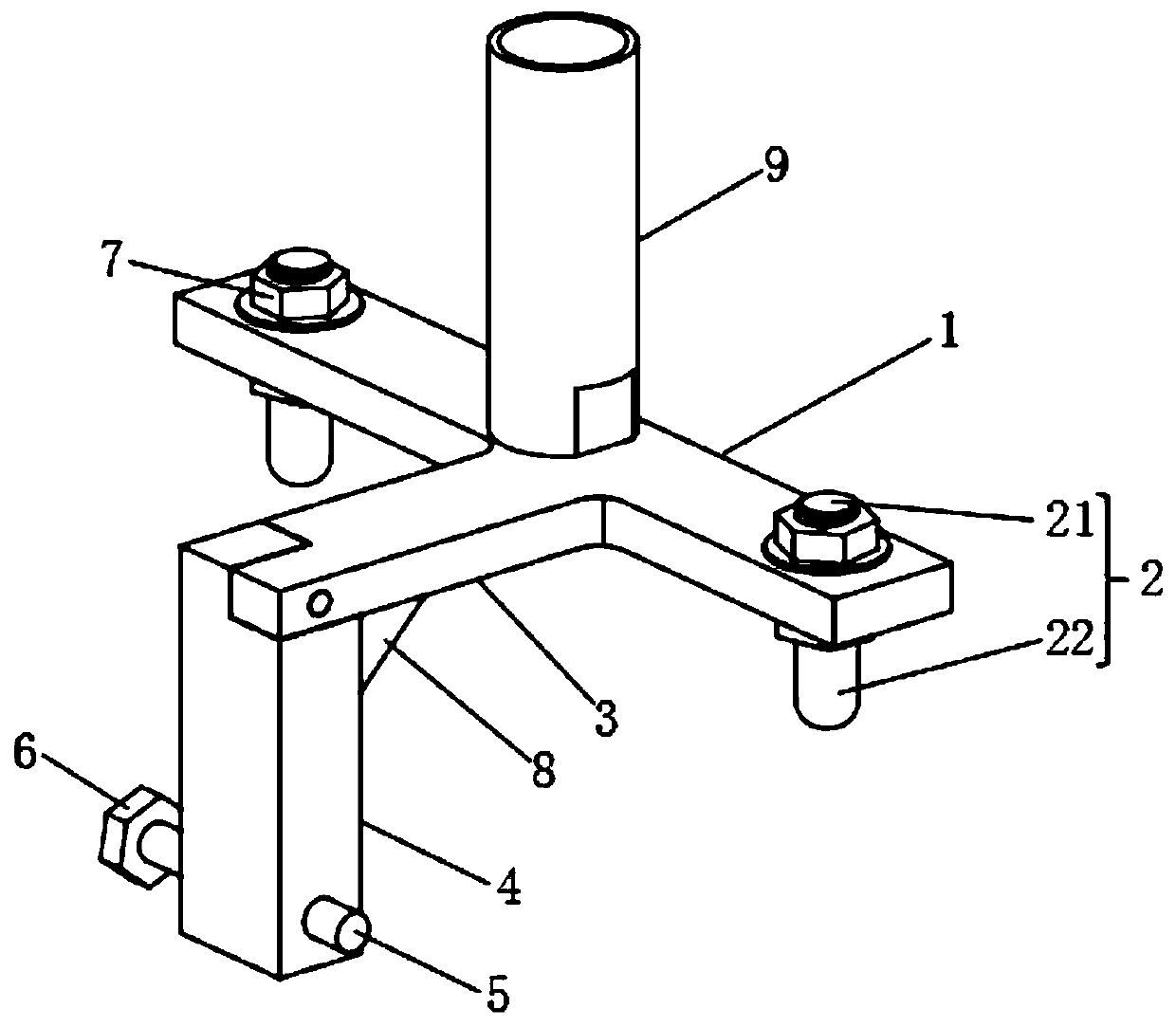

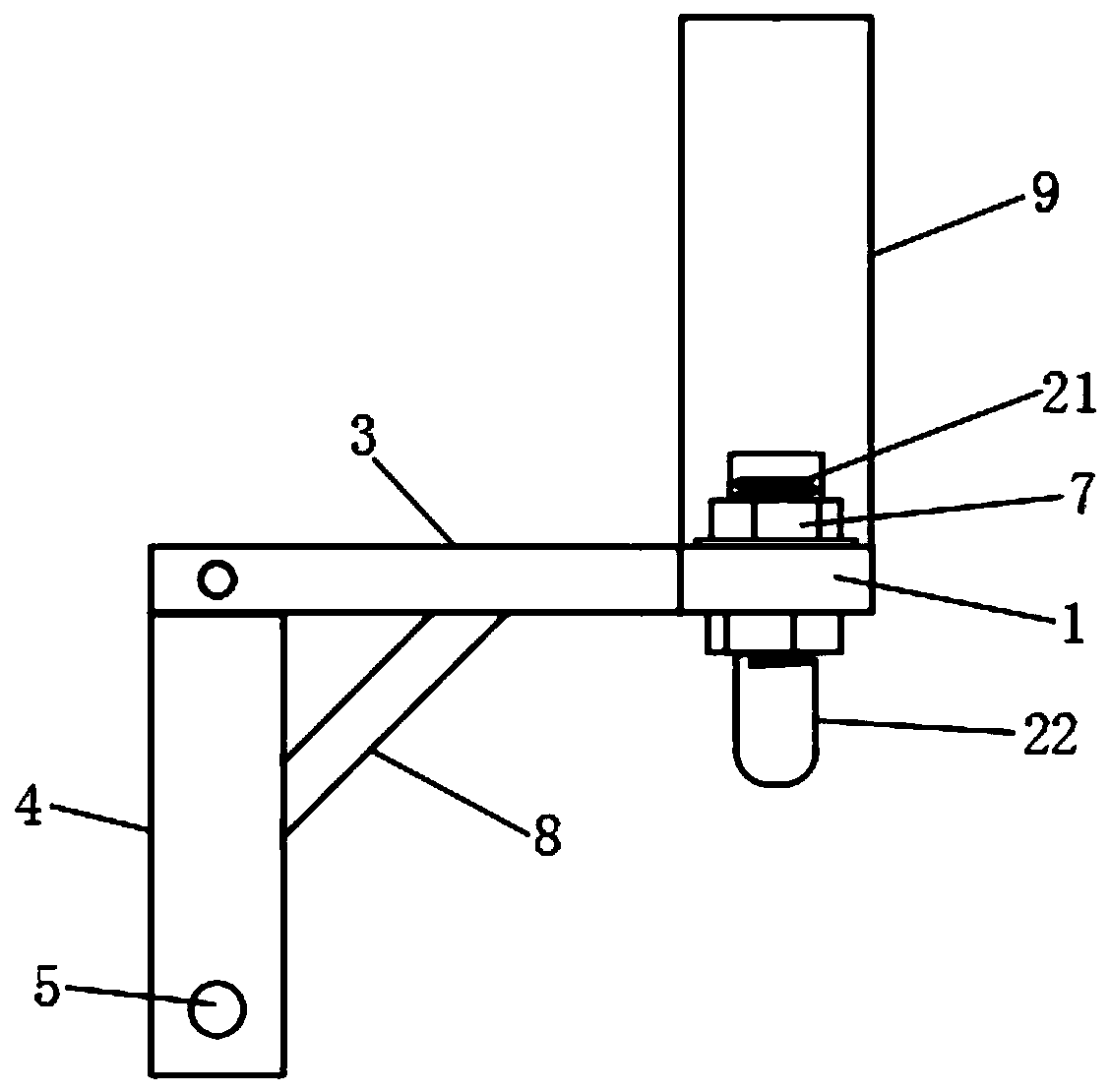

Device for preventing oil injection pump from falling off

A technology of fuel injection pump and supporting connecting rod, which is applied to fuel injection device, fuel injection pump, charging system, etc., can solve the problems of low assembly efficiency, low reliability, and inability to meet production requirements, so as to improve work efficiency , Simple and fast operation, reliable positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

[0024] refer to Figure 1-Figure 2 , a device for preventing the fuel injection pump from falling off according to the present invention includes a positioning rod 1, and at least two positioning pins 2 are detachably mounted on the positioning rod 1, specifically two. One side of the positioning rod 1 is provided with a first support link 3, the end of the first support link 3 is provided with a second support link 4, and the end of the second support link 4 is provided with a front and back adjustable positioning assembly . When in use, place the positioning rod 1 on the cylinder block, insert the positioning pin 2 into the mounting hole of the cylinder block, and use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com