A heat-absorbing light-shielding waterproof, oil-proof and anti-fouling curtain fabric and its preparation method

A waterproof, oil-proof, and anti-fouling technology, which is applied in glass manufacturing equipment, anti-coloring pollution/anti-fouling fibers, manufacturing tools, etc., can solve problems such as inconvenient cleaning and poor heat absorption function, and achieve good waterproof performance and good Endothermic function, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

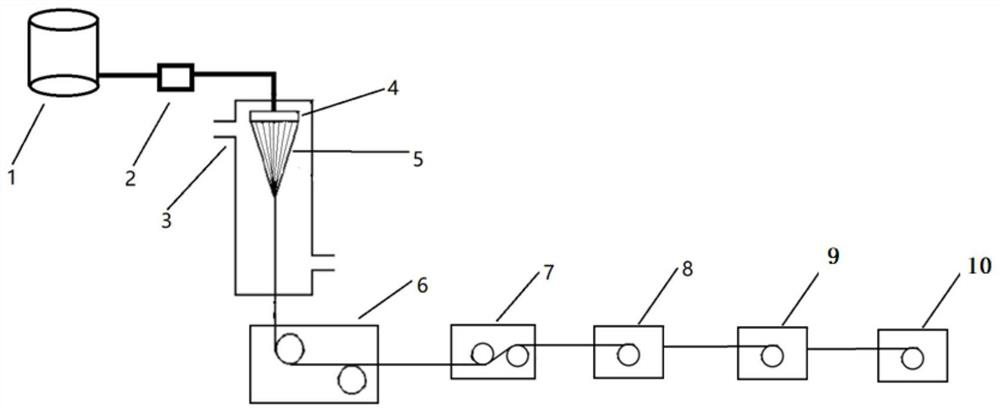

[0029] In the present embodiment, a heat absorption shading waterproof oil-proof anti-fouling curtain fabric preparation method, comprising the following steps:

[0030] (1) ZrO 2 -TiO 2 Preparation of the sol: weigh 10g zirconium pentahydrate, dissolve it in 300mL absolute ethanol, and prepare a mixed solution a; weigh 20mL tetrabutyl titanate, dissolve it in 300mL absolute ethanol to prepare a mixed solution b; 20mL mixed solution a with 300mL mixed solution b to prepare a mixed solution c; 150mL deionized water, 30mL 10% hydrochloric acid aqueous solution dissolved in 300mL absolute ethanol, to obtain a mixed solution d; the mixed solution d dropwise added to the mixed solution c of stirring The drip time is 2 hours, and the initial ZrO is prepared by stirring for 3 hours after the end of the drop 2 -TiO 2 Sol; When it is aged at 30 °C for 6 hours, and its viscosity reaches 55.6 Pa·s, ZrO to be prepared 2 -TiO 2 Sol.

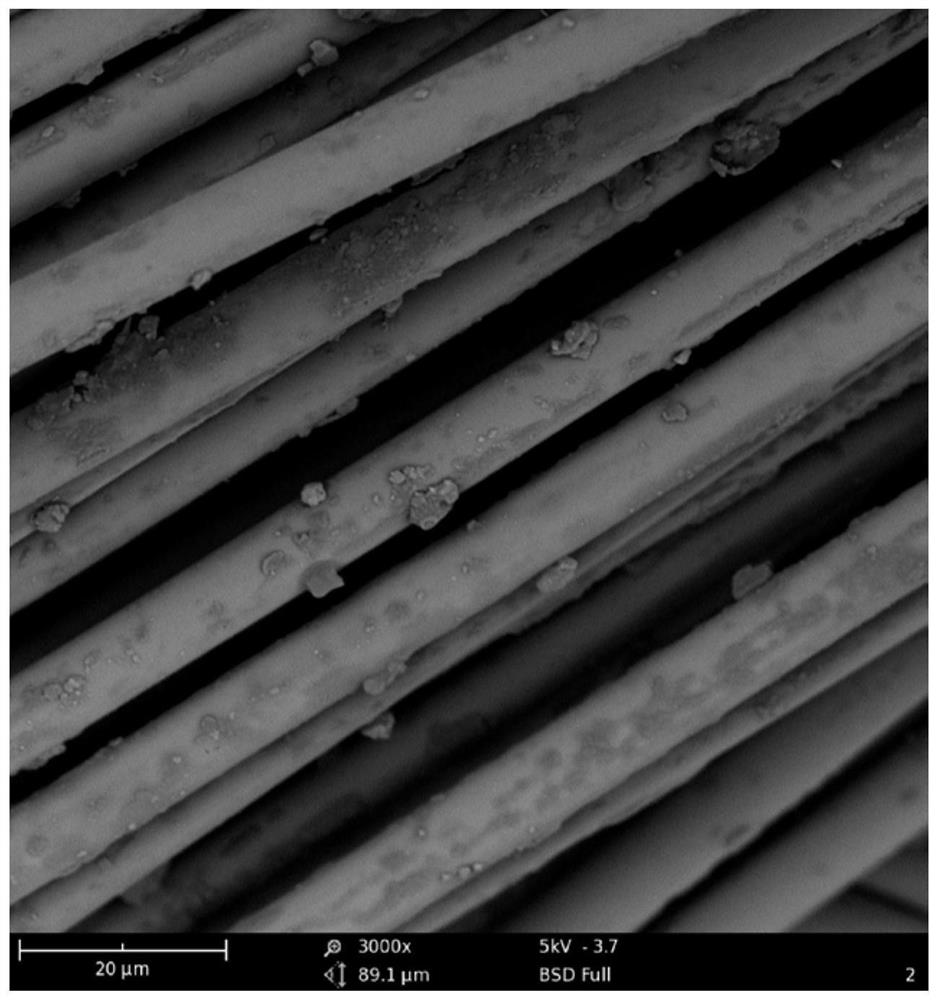

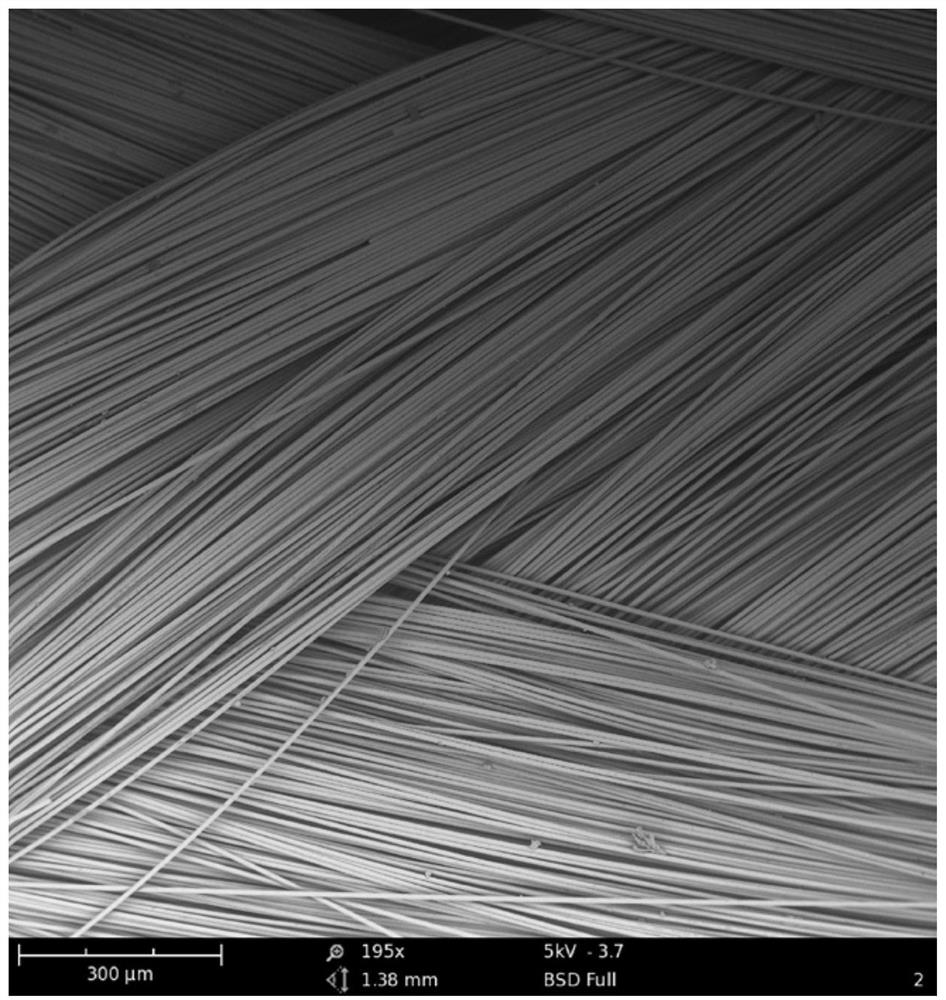

[0031] (2) ZrO 2 -TiO 2 Preparation of fiberglass cloth: Zr...

Embodiment 2

[0035] In the present embodiment, a heat absorption shading waterproof oil-proof anti-fouling curtain fabric preparation method, comprising the following steps:

[0036] (1) ZrO 2 -TiO 2Preparation of the sol: weigh 10g zirconia nitrate pentahydrate, dissolve it in 200mL absolute ethanol, and prepare a mixed solution a; weigh 20mL tetrabutyl titanate, dissolve it in 200mL absolute ethanol to prepare a mixed solution b; 20mL mixed solution a with 200mL mixed solution b to prepare a mixed solution c; 100mL deionized water, 20mL 10% hydrochloric acid aqueous solution dissolved in 200mL absolute ethanol to prepare a mixed solution d; the mixed solution d is added dropwise to the mixed solution c of stirred The drip time is 2 hours, and the initial ZrO is prepared by stirring for 3 hours after the end of the drop 2 -TiO 2 When it is aged at 20 °C for 4 hours, and its viscosity reaches 38.9 Pa·s, ZrO to be spun is prepared 2 -TiO 2 Sol.

[0037] (2) ZrO 2 -TiO 2 Preparation of fiberglas...

Embodiment 3

[0041] In the present embodiment, a heat absorption shading waterproof oil-proof anti-fouling curtain fabric preparation method, comprising the following steps:

[0042] (1) ZrO 2 -TiO 2 Preparation of the sol: weigh 10g zirconium pentahydrate, dissolve it in 400mL of absolute ethanol, and prepare a mixed solution a; weigh 20mL tetrabutyl titanate, dissolve it in 400mL of absolute ethanol to prepare a mixed solution b; 20mL mixed solution a with 400mL mixed solution b to prepare a mixed solution c; 200mL deionized water, 40mL 10% hydrochloric acid aqueous solution dissolved in 400mL absolute ethanol, to prepare a mixed solution d; the mixed solution d was added dropwise to the mixed solution c of the stirred The drip time is 3 hours, and the initial ZrO is prepared by stirring for 4 hours after the end of the drip 2 -TiO 2 Sol; When it is aged at 40 °C for 8 hours, and its viscosity reaches 66.8 Pa·s, ZrO is prepared to be spun 2 -TiO 2 Sol.

[0043] (2) ZrO 2 -TiO 2 Preparation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com