Six-in-one fabric feeding mold

A feeding and fabric technology, applied in the field of six-in-one fabric feeding molds, can solve the problems of difficult to guarantee product quality, complicated operation, low sewing efficiency, etc., and achieve the effect of saving manpower, simple operation and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

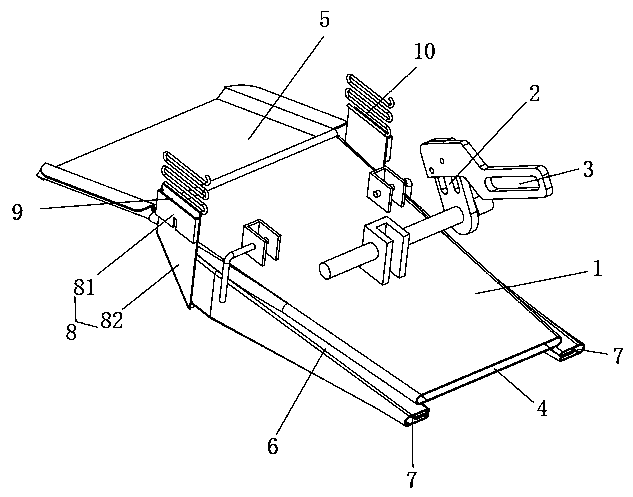

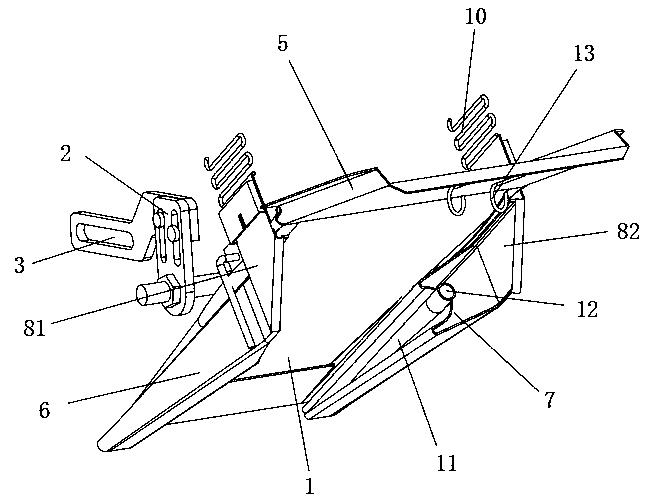

[0031] Example 1, such as figure 1 As shown in the figure, a six-in-one material feeding mold includes a decorative belt guide part and a decorative belt fixing part. A first-level waist-shaped hole is opened on the decorative belt fixing part. Through the cooperation of the first-level waist-shaped hole and the screw, the decorative belt The fixed part is fixed on the machine table. A decorative tape channel for the decorative tape to pass is arranged in the decorative tape guide part, the vertical section of the decorative tape channel is waist-shaped, and is arranged obliquely downward along the feeding direction of the decorative tape. A decorative tape guide plate is welded at the feeding end of the decorative tape guide part, and ribs are arranged on both sides of the decorative tape guide plate, which are used to guide the decorative tape into the decorative tape channel and play a guiding role.

[0032] Such as figure 1 , figure 2 As shown, the two sides of the d...

Embodiment 2

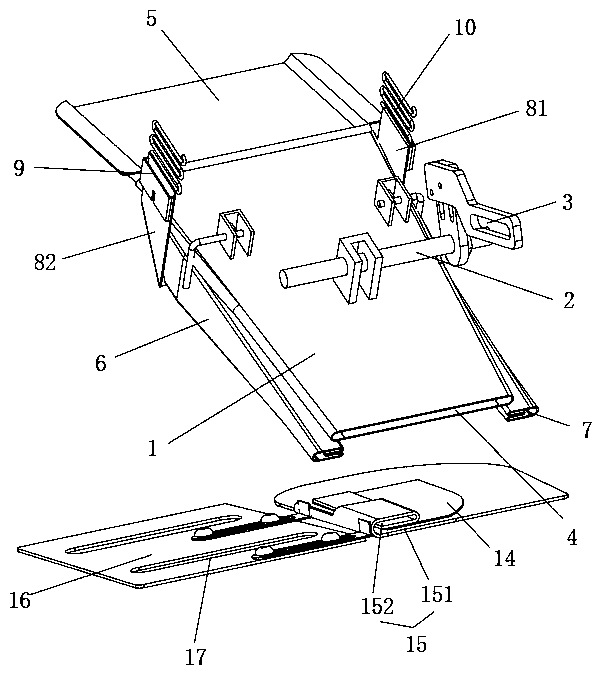

[0039] Such as image 3 , Figure 4 As shown, a six-in-one feeding mold for cloth is different from Embodiment 1 in that it also includes a main cloth guide 14 for leading the main cloth into the sewing machine and folding its edge in half. The main cloth guide is set horizontally, and the decorative tape guide 1 is located obliquely above it and both extend in the same direction, and the vertical projection of the main fabric guide 14 overlaps with the vertical projection of the decorative strip guide 1 .

[0040] Open the main cloth channel 15 in the main cloth guide part 14, the main cloth channel 15 includes the horizontal channel 151 and the bending channel 152 that communicate with each other, the horizontal channel 151 is for the main cloth main body to pass, and the bending channel 152 is used for the main cloth The edge of the main fabric is folded in half. When in use, the main body of the main fabric is inserted into the horizontal channel 151 and its edge is inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com