A kind of oil rich in low saturated fatty acid diglyceride and its preparation method

A technology of fatty acid diglycerides and diglycerides, applied in the direction of fat production, fat oil/fat separation, fermentation, etc., can solve problems such as inability to maintain uniformity, affect sensory quality, precipitation, etc., to reduce fat accumulation and promote crystal nucleation The formation, the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

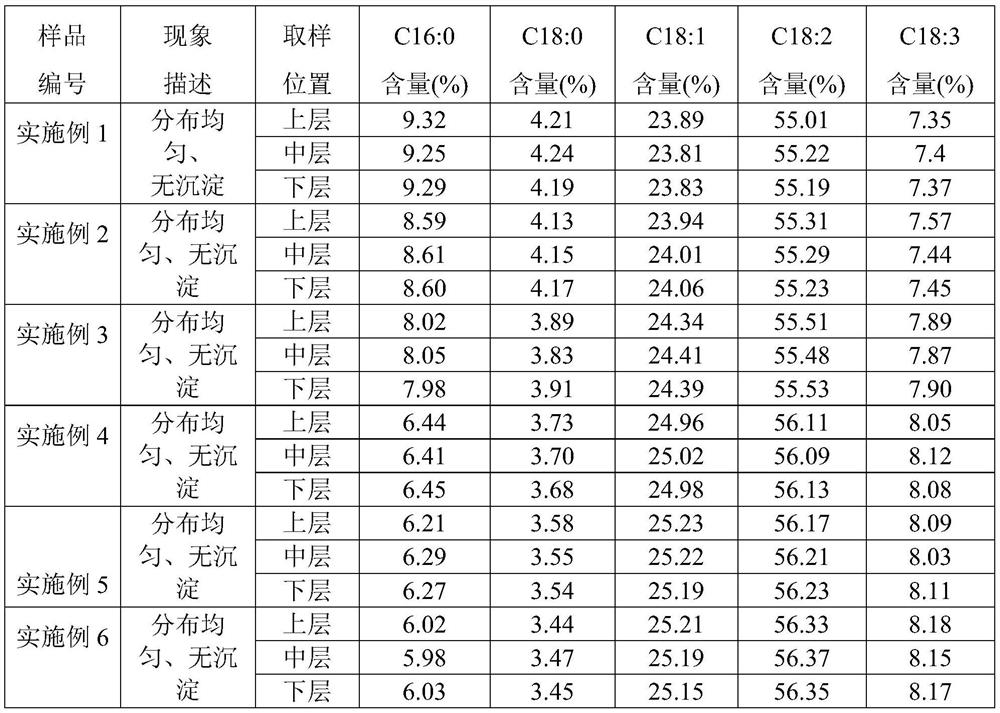

Embodiment 1

[0032]Put 500g of fatty acid mixture (14% palmitic acid, 6% stearic acid, 21% oleic acid, 52% linoleic acid, 5% linolenic acid) into 60°C for half an hour to eliminate historical crystallization, and use 5°C / h Reduce to the required crystallization temperature. Add 0.2% of palmitic acid monoglyceride and crystallize at 10°C for 3 hours to form stable crystals for subsequent separation. After crystal growth, the solid fatty acids are removed by suction filtration. Enzymatic esterification method is used to prepare diglycerides by reacting low-saturation fatty acids with glycerol. The reaction conditions are: the molar ratio of glycerol to fatty acids is 4:1, and Lipase PCL (from "CN108642026A, a partial glyceride fat The addition amount of the enzyme disclosed in "Enzyme mutant and its application" is 5% of the total mass, and the reaction temperature is 35°C. After the reaction time under vacuum was 24 hours, the mixture was centrifuged, the upper oil phase was recovered, and the fa...

Embodiment 2

[0034]Put 500g of fatty acid mixture (14% palmitic acid, 6% stearic acid, 21% oleic acid, 52% linoleic acid, 5% linolenic acid) into 60°C for half an hour to eliminate historical crystallization, and use 5°C / h Reduce to the required crystallization temperature. 0.2% of palmitic acid monoglyceride was added and crystallized at 10°C for 6 hours to form stable crystals for subsequent separation. After crystal growth, the solid fatty acids are removed by suction filtration. The enzymatic esterification method is used to react low-saturation fatty acids with glycerol to prepare diglycerides. The reaction conditions are: the molar ratio of glycerol to fatty acids is 4:1, and the addition amount of lipase Lipase PCL is 5% of the total mass. The temperature is 35°C. After the reaction time under vacuum is 24h, the mixture is centrifuged, the upper oil phase is recovered and the fatty acids and monoglycerides are separated and removed by molecular distillation to obtain oil 2 with diglycerid...

Embodiment 3

[0036]Put 500g of fatty acid mixture (14% palmitic acid, 6% stearic acid, 21% oleic acid, 52% linoleic acid, 5% linolenic acid) into 60°C for half an hour to eliminate historical crystallization, and use 5°C / h Reduce to the required crystallization temperature. 0.2% of palmitic acid monoglyceride was added and crystallized at 10°C for 12 hours to form stable crystals for subsequent separation. After crystal growth, the solid fatty acids are removed by suction filtration. The enzymatic esterification method is used to react low-saturation fatty acids with glycerol to prepare diglycerides. The reaction conditions are: the molar ratio of glycerol to fatty acids is 4:1, and the addition amount of lipase Lipase PCL is 5% of the total mass. The temperature is 35°C. After the reaction time under vacuum was 24 hours, the mixture was centrifuged, the upper oil phase was recovered and the fatty acids and monoglycerides were separated and removed by molecular distillation to obtain oil 3 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com