ABS induction mode structure of automobile drive rear axle

An ABS ring gear and automobile technology, applied in the direction of brakes, brake components, vehicle parts, etc., can solve the problems of difficult maintenance and air gap control, and achieve easy air gap assurance, improved coaxiality, and easy after-sales maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

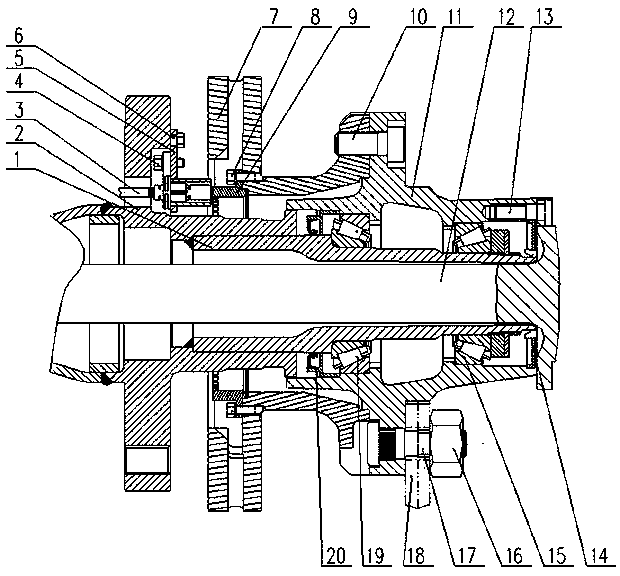

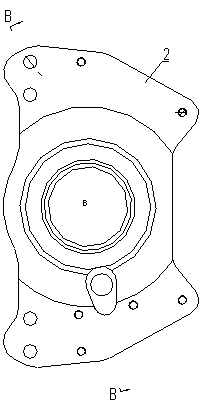

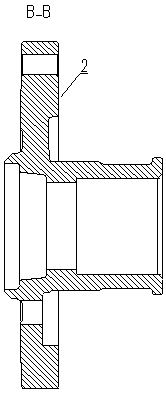

[0036] Such as Figure 1 to Figure 8 As shown in the figure, a structure of the ABS induction mode of the automobile drive rear axle includes an ABS sensor fixing structure and an ABS ring gear fixing structure, and the ABS sensor fixing structure includes a half shaft sleeve 1, a flange 2, an ABS sensor 3, and an M6 screw 4 , ABS sensor bracket 5, M8 screw 6. The ABS sensor 3 is fixed on the ABS sensor bracket 5 through the M6 screw 4, the ABS sensor bracket 5 is fixed on the flange 2 through the M8 screw 6, and the flange 2 and the half shaft sleeve 1 are welded and connected;

[0037] ABS ring gear fixing structure, brake disc 7, M6 screw 8, ABS ring gear 9, brake chassis bolt 10, wheel hub 11, half shaft 12, half shaft bolt 13. The ABS ring gear 9 is fixed on the brake disc 7 by screws 8 , the brake disc 7 is fixed on the wheel hub 11 by the brake chassis bolts 10 , and the wheel hub 11 and the half shaft 12 are fixedly connected by the half shaft bolts 13 .

[0038] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com