Non-woven fabric edge cutting machine

A technology of edge trimming machine and non-woven fabric, which is applied in textile and papermaking, cutting of textile materials, metal processing, etc., can solve the problems of increasing the labor intensity of operators, reducing work efficiency, etc., to improve the scope of application and improve production efficiency. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

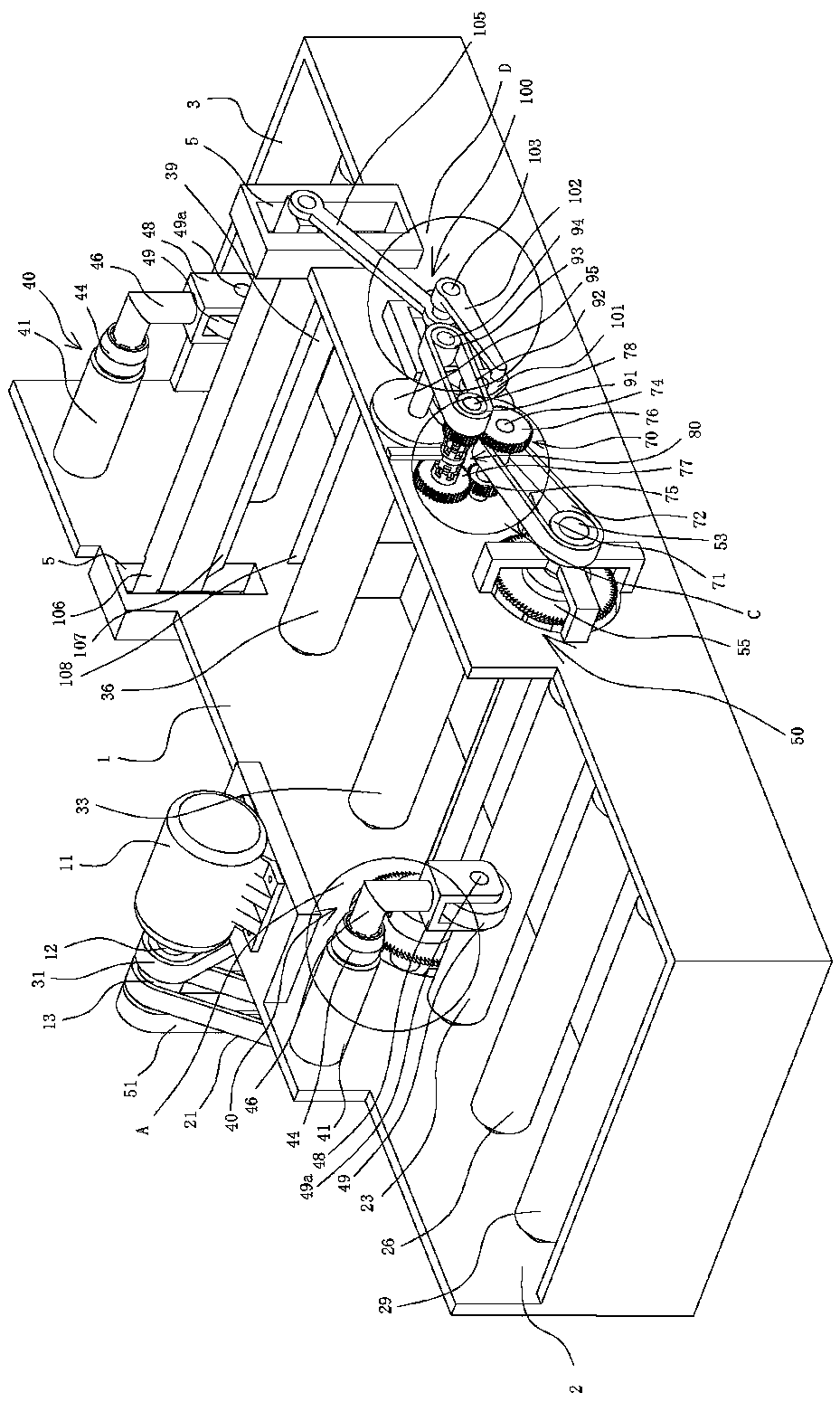

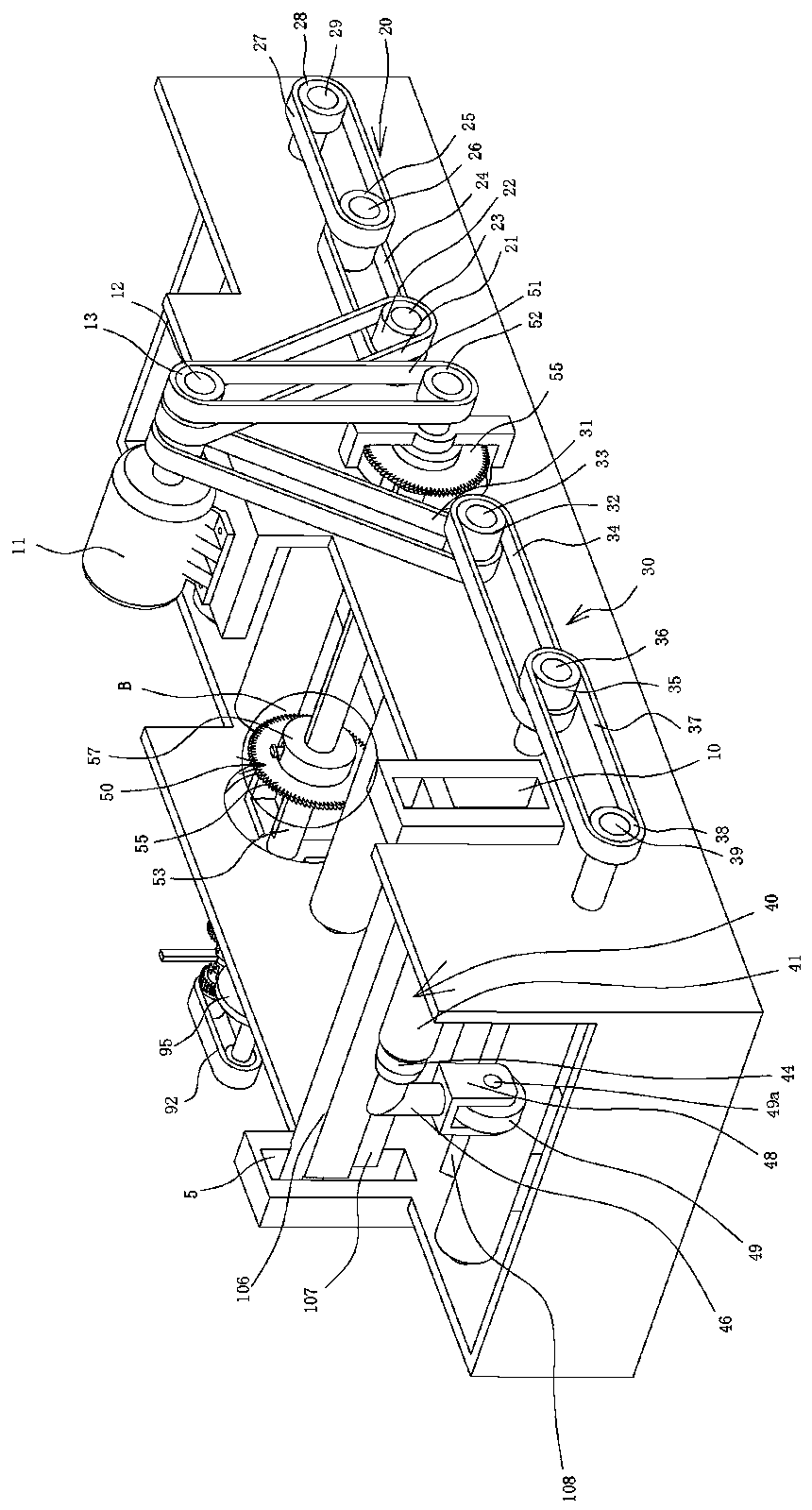

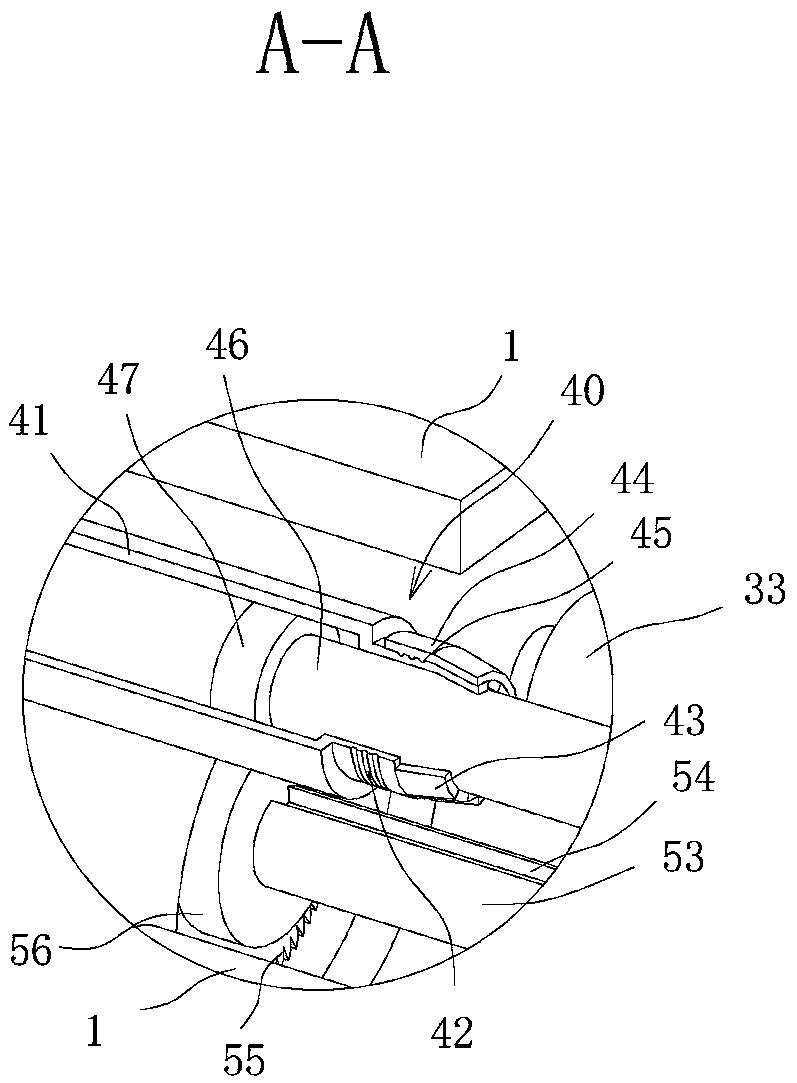

[0030] Such as figure 1 and figure 2 As shown, the non-woven fabric trimming machine of the present invention comprises a frame 1, the left side of the frame 1 is provided with a material inlet 2, the right side of the frame 1 is provided with a discharge port 3, and the upper end of the frame 1 is provided with a motor 11, and the motor The front end of 11 is provided with a power shaft 12, and the front end of the power shaft 12 is provided with a driving pulley 13, and the driving pulley 13 is threadedly engaged with the power shaft 12, and the left side of the driving pulley 13 is provided with a first conveying mechanism 20, and the first conveying mechanism 20 The right side is provided with the second conveying mechanism 30, and the second conveying mechanism 30 links to each other with driving pulley 13, and frame 1 front end inner wall is provided with two fixing mechanisms 40, and driving pulley 13 lower end is provided with cutting mechanism 50, and after cutting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com