A double-station automatic feeding riveting machine

An automatic feeding and riveting machine technology, applied in the field of riveting machines, can solve the problems of low processing efficiency and achieve the effects of saving output, increasing working speed and improving working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

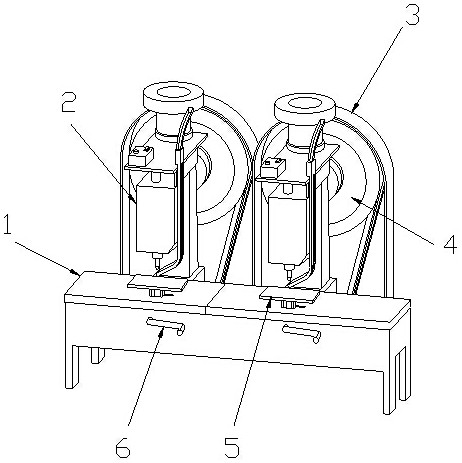

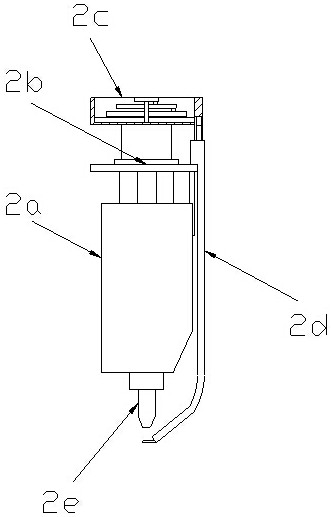

[0028] see Figure 1-Figure 6 , the present invention provides a double-station automatic feeding riveting machine, its structure includes a workbench 1, a duplex riveting machine 2, a dust cover 3, a driving device 4, a placement plate 5, a slide rail handwheel rod 6, the described A duplex riveting machine 2 is installed on the workbench 1, a placement plate 5 is provided on the top of the workbench 1, the workbench 1 and the placement plate 5 are movably connected, and a slide is provided on the front end of the workbench 1. Rail handwheel bar 6, the workbench 1 and the slide rail handwheel bar 6 adopt clearance fit, and the driving device 4 is installed on the rear end of the duplex riveting machine 2, and the surface of the driving device 4 is provided with The dust cover 3, the driving device 4 is connected with the dust cover 3, and the duplex riveting machine 2 is composed of a gear box 2a, a support plate 2b, a material storage box 2c, an automatic feeding mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com