A threading device for cable installation

A technology of cable installation and wire holder, which is applied in the direction of cable installation device, cable installation, equipment for connecting/terminating cables, etc., which can solve the problems of time-consuming and labor-intensive, increasing construction period of power plants and substations, affecting acceptance and commissioning progress, etc. problem, to achieve the effect of speeding up the threading speed and adapting to a wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

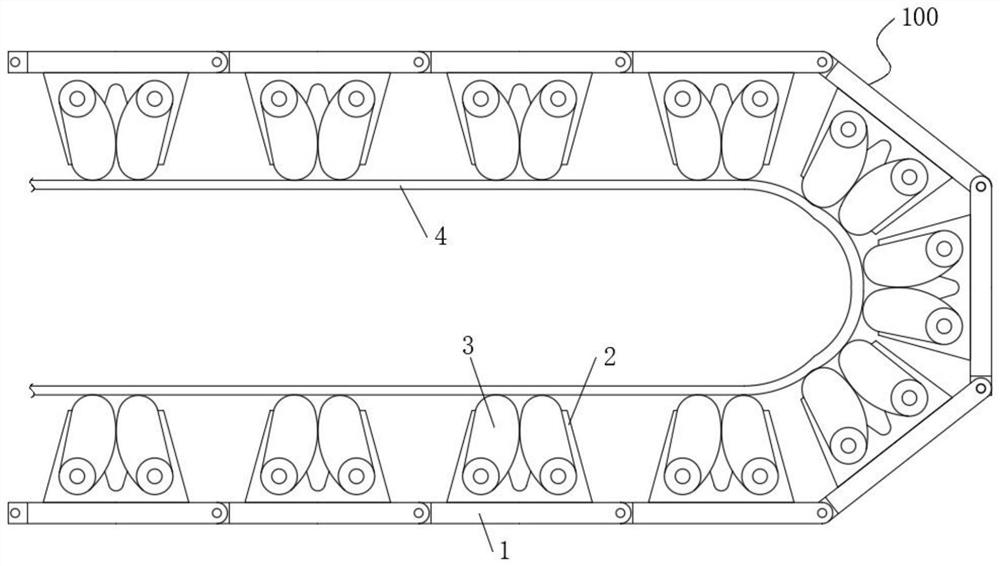

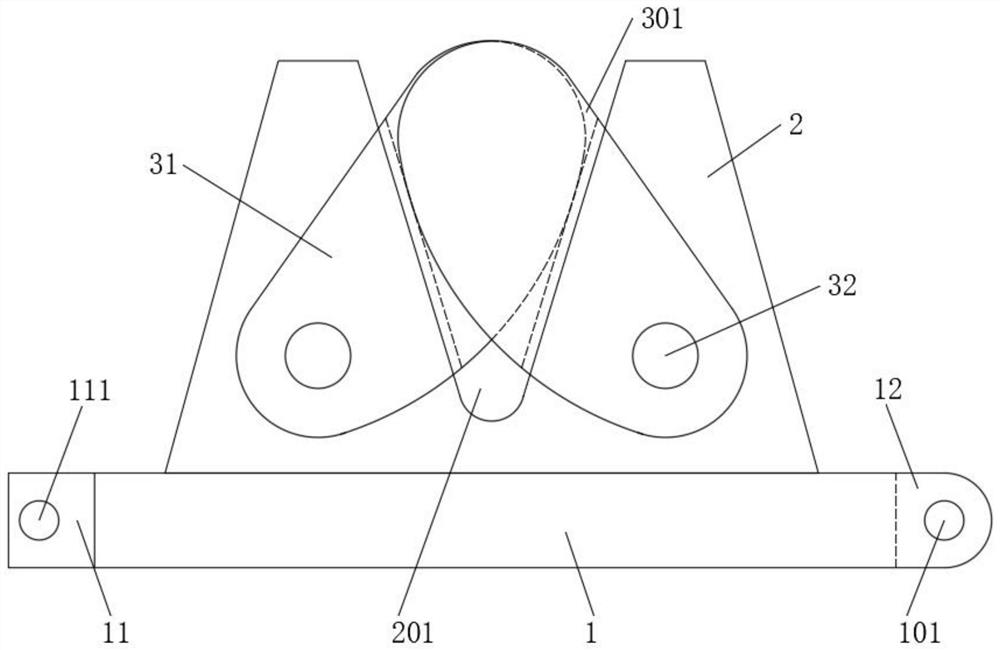

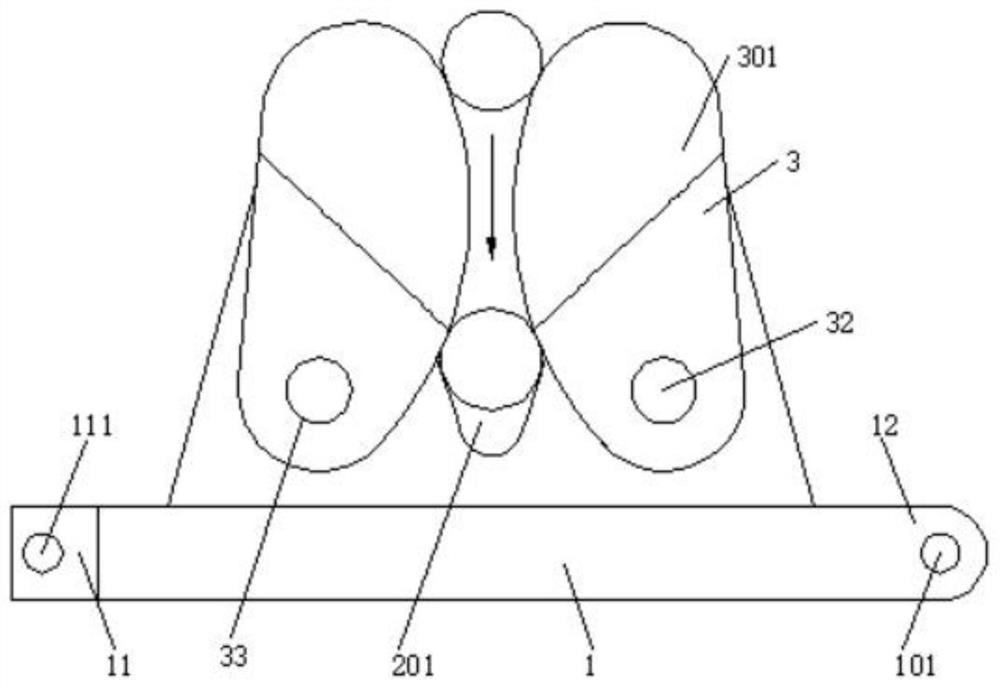

[0028] The difference from Embodiment 1 is that the wire-pulling seat 2 is evenly installed on both sides of the chain link plate 1, and multiple cables can be placed in the wire grooves 201 of different wire-pulling seats 2 at the same time, which can accommodate more cables. Compared with the first embodiment, the cable has twice the installation amount of the cable, and the speed of the cable is faster, and then the cable-stripping device 100 is pulled. The chain link plates 1 are hinged and rotated with each other, so that the thread-stripping device 100 can not only be in a plane shape, but also can be bent into an arc or circle, which can be selected according to the requirements of the thread-stripping device, so that the thread-stripping device 100 is more flexible. After the wire is stretched, the sticker 4 can also be pasted on the outside of the cable extrusion mechanism 3 to fix the cable, act as a wire clip, position the cable, and can be reused. When in use, you c...

Embodiment 3

[0030] The difference from Embodiment 1 is that the wire-pulling bases 2 are installed on both sides of the chain link plate 1 in a staggered manner, and multiple cables can be placed in the wire grooves 201 of different wire-pulling bases 2 at the same time. According to the distribution situation, any combination of the wire-pulling seat 2 can be used to adapt to the wire-pulling state of more complicated situations, so that the wire-pulling speed is faster, and then the wire-pulling device 100 is pulled to complete the wire-pulling work on the multi-strand cables. The chain link plates 1 are hinged and rotated with each other, so that the thread-stripping device 100 can not only be in a plane shape, but also can be bent into an arc or circle, which can be selected according to the requirements of the thread-stripping device, so that the thread-stripping device 100 is more flexible. After the wire is stretched, the sticker 4 can also be pasted on the outside of the cable extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com