Injectable composite bone cement with photothermal effect and preparation method and application thereof

A photothermal effect, bone cement technology, applied in pharmaceutical formulations, prostheses, drug delivery, etc., can solve the problem of single function of bone cement, and achieve the effect of promoting wound healing, good injectability, and promoting repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

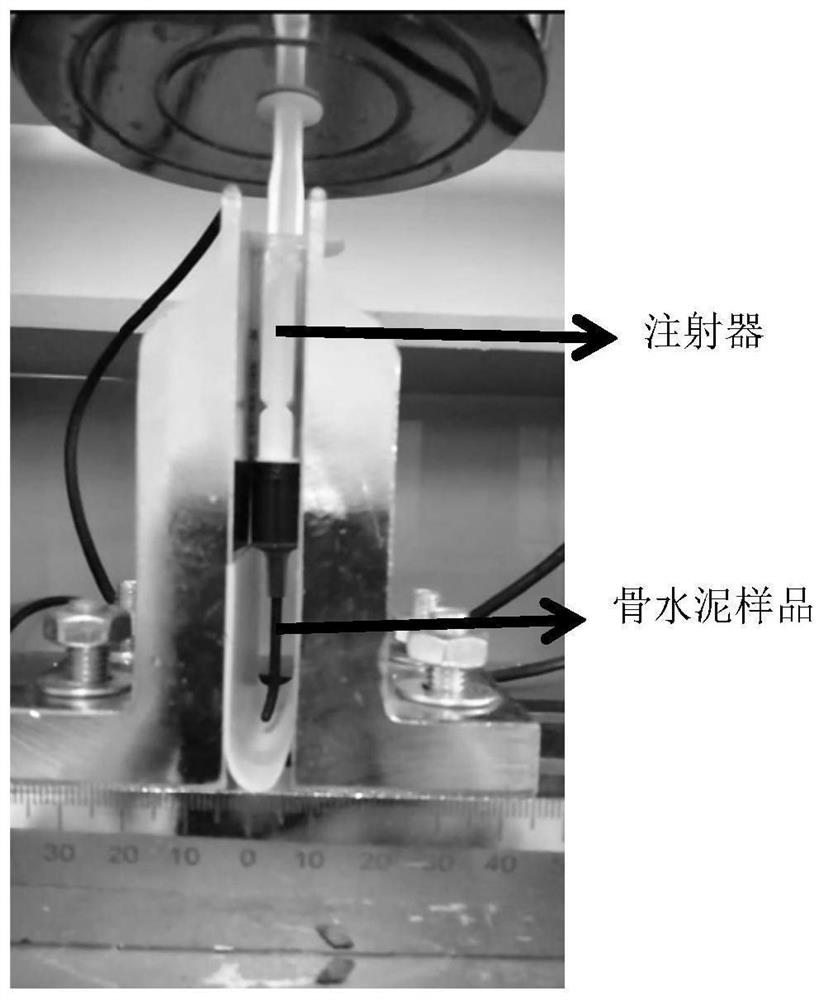

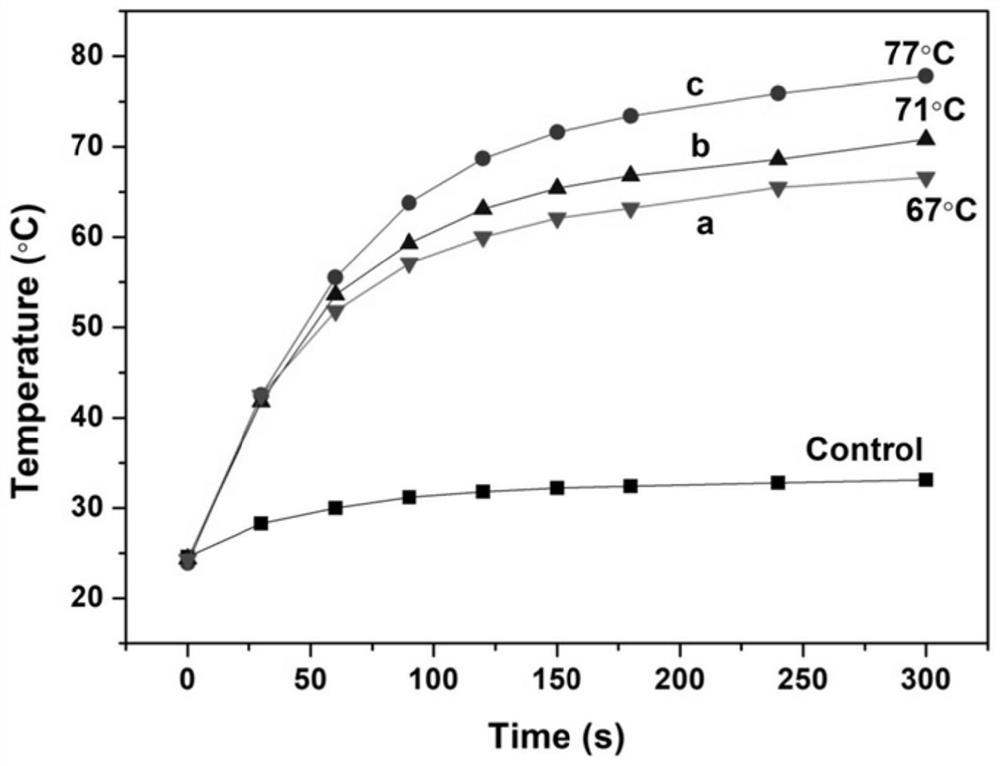

Method used

Image

Examples

Embodiment 1

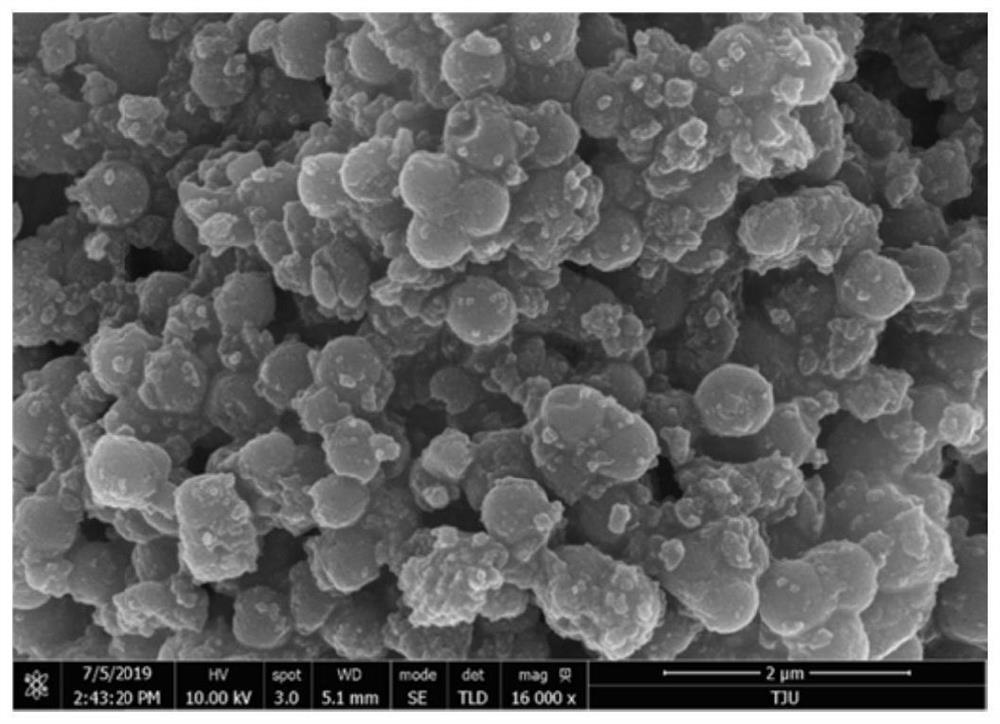

[0035] (1) Preparation of mixed powder (bone cement solid phase) of biological glass powder and titanium nitride nanopowder

[0036] Prepare the bone cement solid phase with the following mass percentages of each component: the particle size is 30-40 microns, and the silicate bioactive glass 45S5 (45SiO 2 -24.5Na 2 O-24.5CaO-6P 2 o 5 , wt%) powder 60%, titanium nitride nanometer powder 10%. Put 6g of biological glass powder and 1g of titanium nitride nanometer powder (average particle size is 20nm) in a mortar, grind and mix at room temperature for 3min, and obtain the solid phase of bone cement.

[0037] (2) Preparation of sodium alginate mixed solution (bone cement liquid phase)

[0038]Prepare the bone cement liquid phase with the following mass percentages of the components: 3% sodium alginate, 2% gluconolactone, 3% disodium hydrogen phosphate, and 92% deionized water. Add 3g of sodium alginate, 2g of gluconolactone, and 3g of disodium hydrogen phosphate into 92g of d...

Embodiment 2

[0047] (1) Preparation of mixed powder of biological glass powder and titanium nitride nanopowder

[0048] Prepare the bone cement solid phase with the following mass percentages of each component: the particle size is 20-40 microns, borate bioactive glass (6Na 2 O-8K 2 O-22CaO-8MgO-54B 2 o 3 -2P 2 o 5 , wt%) powder 50%, titanium nitride nano powder 20%. 5 g of borate bioglass powder and 2 g of titanium nitride nano powder (average particle size 20 nm) were placed in a mortar, ground and mixed at room temperature for 5 min to obtain a solid phase of bone cement.

[0049] (2) Preparation of sodium alginate mixed solution

[0050] The mass percentage of each component was prepared as follows bone cement liquid phase: sodium alginate 3%, gluconolactone 4%, disodium hydrogen phosphate 4%, deionized water 89%. Add 3g of sodium alginate, 4g of gluconolactone, and 4g of disodium hydrogen phosphate into 89g of deionized water in sequence, and stir magnetically at room temperatu...

Embodiment 3

[0056] (1) Preparation of mixed powder of biological glass powder and titanium nitride nanopowder

[0057] Prepare the bone cement solid phase with the following mass percentages of each component: the particle size is 50-100 nanometers, and the silicate bioactive glass (30CaO-70SiO 2 , wt%) powder 30%, titanium nitride nano powder 30%. Put 3g of silicate bioglass powder and 3g of titanium nitride nanometer powder (average particle size is 20nm) in a mortar, grind and mix at room temperature for 3min, and obtain the solid phase of composite bone cement.

[0058] (2) Preparation of sodium alginate mixed solution

[0059] Prepare the bone cement liquid phase in mass percent as follows: sodium alginate 4%, gluconolactone 4%, disodium hydrogen phosphate 4%, deionized water 88%. Add 4g of sodium alginate, 4g of gluconolactone, and 4g of disodium hydrogen phosphate into 88g of deionized water in sequence, and stir magnetically at room temperature for 1 hour to make the solution cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com