Automatic multi-row adjustable seedling cuttage device

An automatic technology for planting seedlings, applied in horticulture, application, vegetative propagation, etc., can solve the problems of low technical level, difficulty in reaching the international level of sapling planting mechanization, and inadequate promotion work, so as to avoid repeated work and avoid The effect of low land utilization rate and shortened planting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

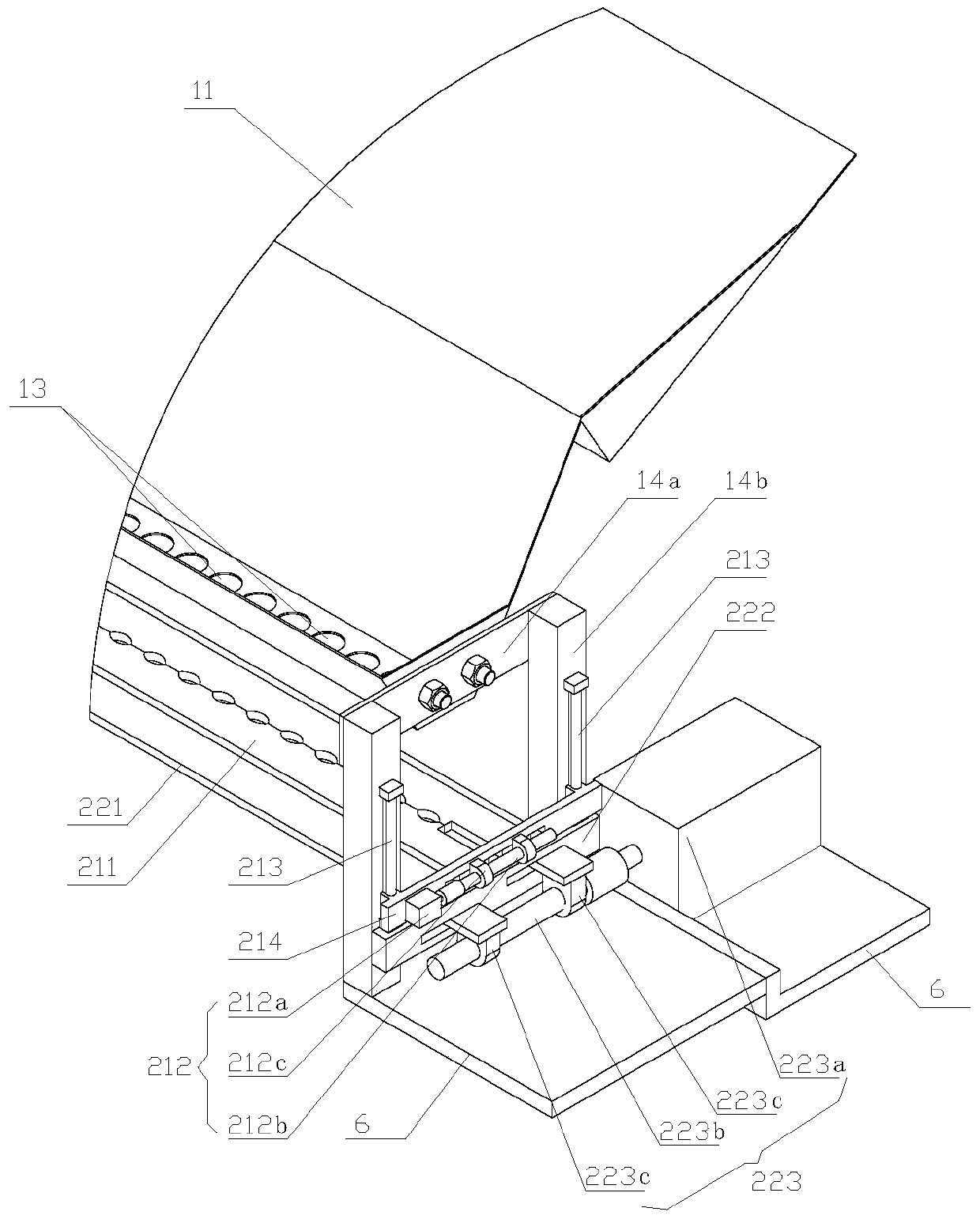

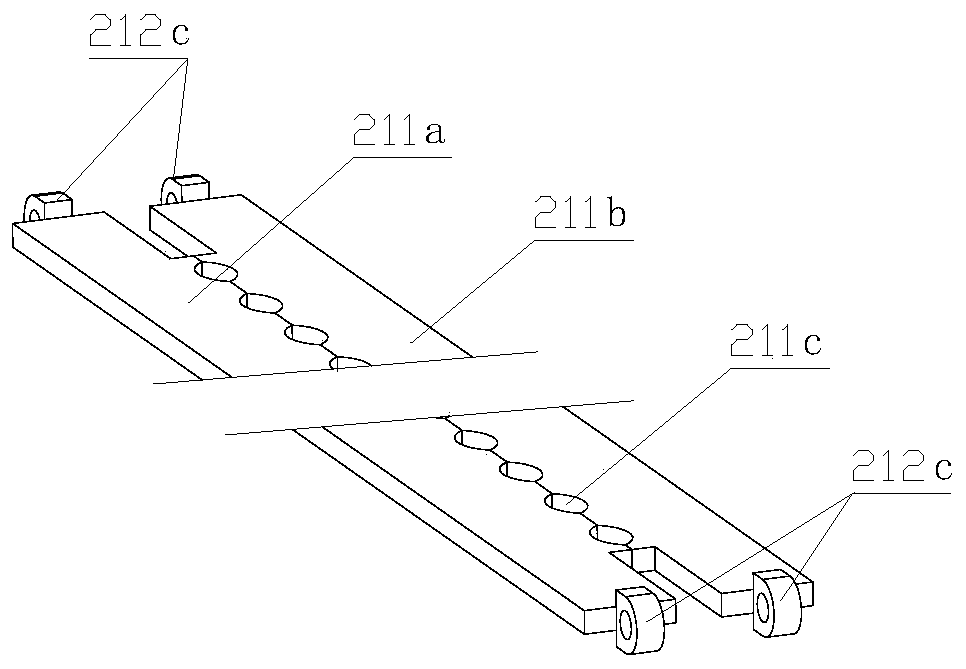

[0054] The present invention will now be described in detail with reference to the drawings. This figure is a simplified schematic diagram, which only illustrates the basic structure of the present invention in a schematic manner, so it only shows the structure related to the present invention.

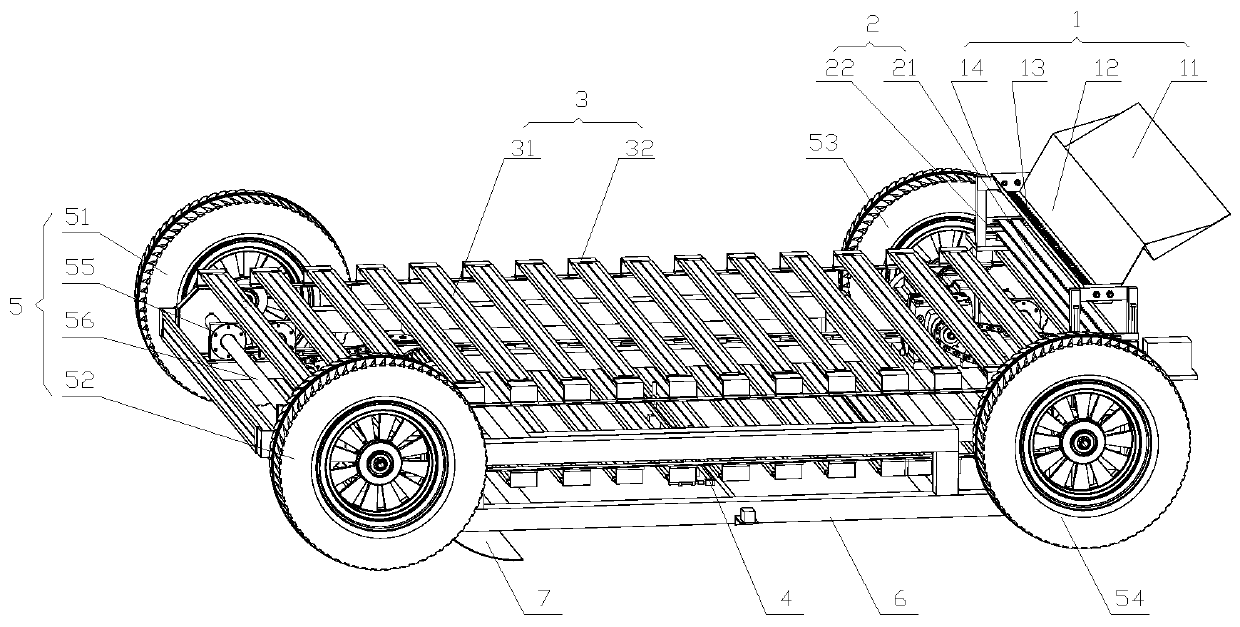

[0055] Such as figure 1 As shown, an automatic multi-row adjustable seedling planting device of the present invention includes a loading mechanism 1, a shearing mechanism 2, a conveying mechanism 3, a seedling planting mechanism 4, a moving mechanism 5 and a main body support 6. Among them, the loading mechanism 1 is located above the seedling device and is used to load seedlings at a certain interval; the loading mechanism 1 can be fixed on the seedling device, and the operator can directly arrange the seedlings; it can also be replaceable, and can be used for inserting seedlings. The process is not carried out on the planting device, so that multiple people can arrange seedlings to rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com