MBD-based aircraft complex structural part collaborative design implementation method

A technology for aircraft structural parts and collaborative design, applied in design optimization/simulation, calculation, geometric CAD, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following describes the embodiment of the present invention in detail from the two aspects of MBD model construction and multi-Agent collaborative workflow implementation.

[0032] Construct MBD model of aircraft component tooling

[0033] The collaborative tooling MBD tooling model consists of tooling parts, tooling components, characteristics, annotations and attributes. The tooling components can be divided into main geometry, auxiliary geometry, reference geometry, features, annotations, and attributes, which can be expressed by the following formula:

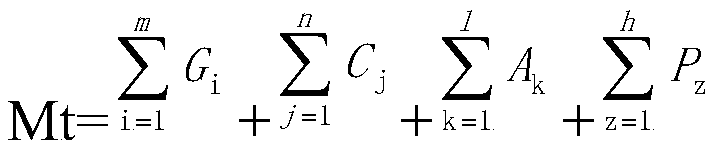

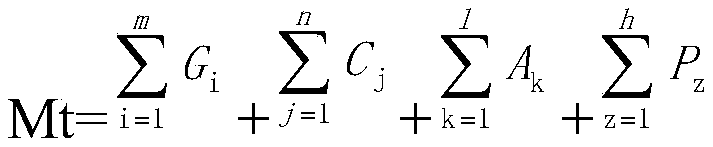

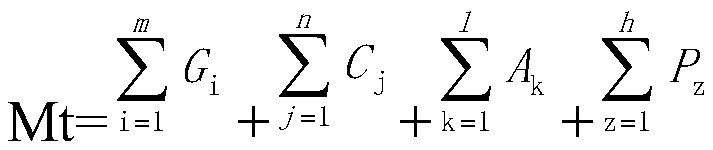

[0034]

[0035] Among them, M t represents the tooling MBD model (t=1, 2,...); G i represents the geometric feature elements in the MBD model; C j represents the characteristic information in the MBD model; A k represents the annotation information in the MBD model; P z represents the attribute information in the MBD model.

[0036] The geometric feature elements G i in the model include main geometric elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com