Batch processing method of flame-retardant cellulose staple fiber and obtained flame-retardant cellulose staple fiber

A technology of flame-retardant cellulose and short fiber, which is applied in the direction of flame-retardant fiber, plant fiber, fiber treatment, etc., can solve the problems of reducing flame-retardant effect, loss, and inability to apply flame-retardant processing of short fiber, and achieve flame-retardant Effects of performance improvement and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

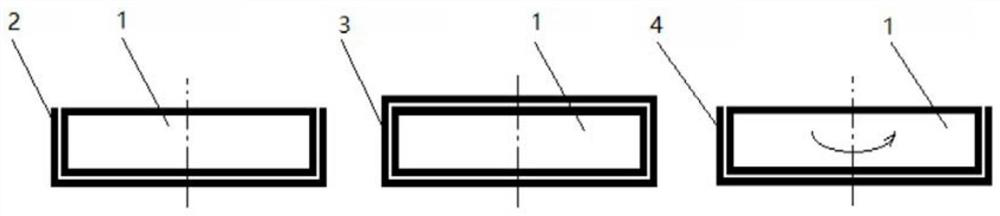

Image

Examples

Embodiment 1

[0070] Example 1: A100 type Tencel produced by Lenzing, Austria, uses tetramethylolphosphorus chloride as a flame retardant.

[0071] The fiber with 100% fiber weight is transported by air flow from the cotton box feeder into the mesh cage, and at the same time, the swelling liquid is input, and the swelling liquid is combined with the squeezing action of the cake beater to make the fibers absorb the swelling liquid and make the fiber. The fibers were in a relatively dense state and were impregnated with a swelling solution at a temperature of 65 °C for 25 min. The swelling liquid contains: 70g / L NaOH (Jinan Star Chemical), 3.5g / L degreaser (Deoiling 101, Jinan Yutao Chemical), 2.5g / L penetrant (penetrant OE, Jiangsu Provincial Hai'an Petrochemical Plant), 2.5g / L of refining agent (refining agent SP, Nanjing Qixiashan Printing and Dyeing Auxiliary Factory), 30g / L of urea (Changzhou Shanglian Chemical Co., Ltd.). After the swelling liquid treatment is completed, the cage is ho...

Embodiment 2

[0082] Example 2: Tencel produced by Shanghai Leo Company, using tetrahydroxymethyl phosphorus sulfate as a flame retardant.

[0083] The fiber with 100% fiber weight is transported by air flow from the cotton box feeder into the mesh cage, and at the same time, the swelling liquid is input, and the swelling liquid is combined with the squeezing action of the cake beater to make the fibers absorb the swelling liquid and make the fiber. The fibers were in a relatively dense state and were impregnated with a swelling solution at a temperature of 35 °C for 28 min. The swelling liquid contains: 60g / L KOH (Jinan Jinhao Chemical Co., Ltd.), 3g / L degreaser (Deoiling 101, Jinan Yutao Chemical Industry), 4g / L penetrant (penetrant OE, Jiangsu Haian Petrochemical Plant), 3g / L of refining agent (refining agent SP, Nanjing Qixiashan Printing and Dyeing Auxiliary Factory), and 40g / L of surfactant (anionic surfactant L-450, Guangzhou Shengxin Chemical Technology Ltd). After the swelling li...

Embodiment 3

[0094] Example 3: Cotton fiber, using tetrahydroxymethyl phosphorus sulfate as a flame retardant.

[0095]The cotton fiber with 100% fiber weight is transported by air flow from the cotton box feeder into the mesh cage, and the swelling liquid is input at the same time, and the swelling liquid is combined with the squeezing action of the cake beater to make the cotton fiber absorb the swelling liquid. And make the fiber in a relatively dense state, soak it with the swelling liquid at a temperature of 50°C for 20min. The swelling liquid contains: 40g / L NaOH, 3g / L degreaser (Deoiling TF-101, Zhejiang Transfar Co., Ltd.), 3g / L penetrant (JFC, Taixing Hengyuan Chemical Factory) , 4g / L of refining agent (SL-J02, Zhongshan Senlian Textile New Material Technology Co., Ltd.). After the swelling liquid treatment is completed, the cage is transferred to the centrifugal dehydrator to be dried, and the high-speed centrifugal dehydrator is adjusted to the water storage state with 80 ℃ hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com