Novel vibration reduction motor support

A motor bracket, a new type of technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problem of serious radial shaking of the pump motor, reduce radial shaking and ensure axial output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

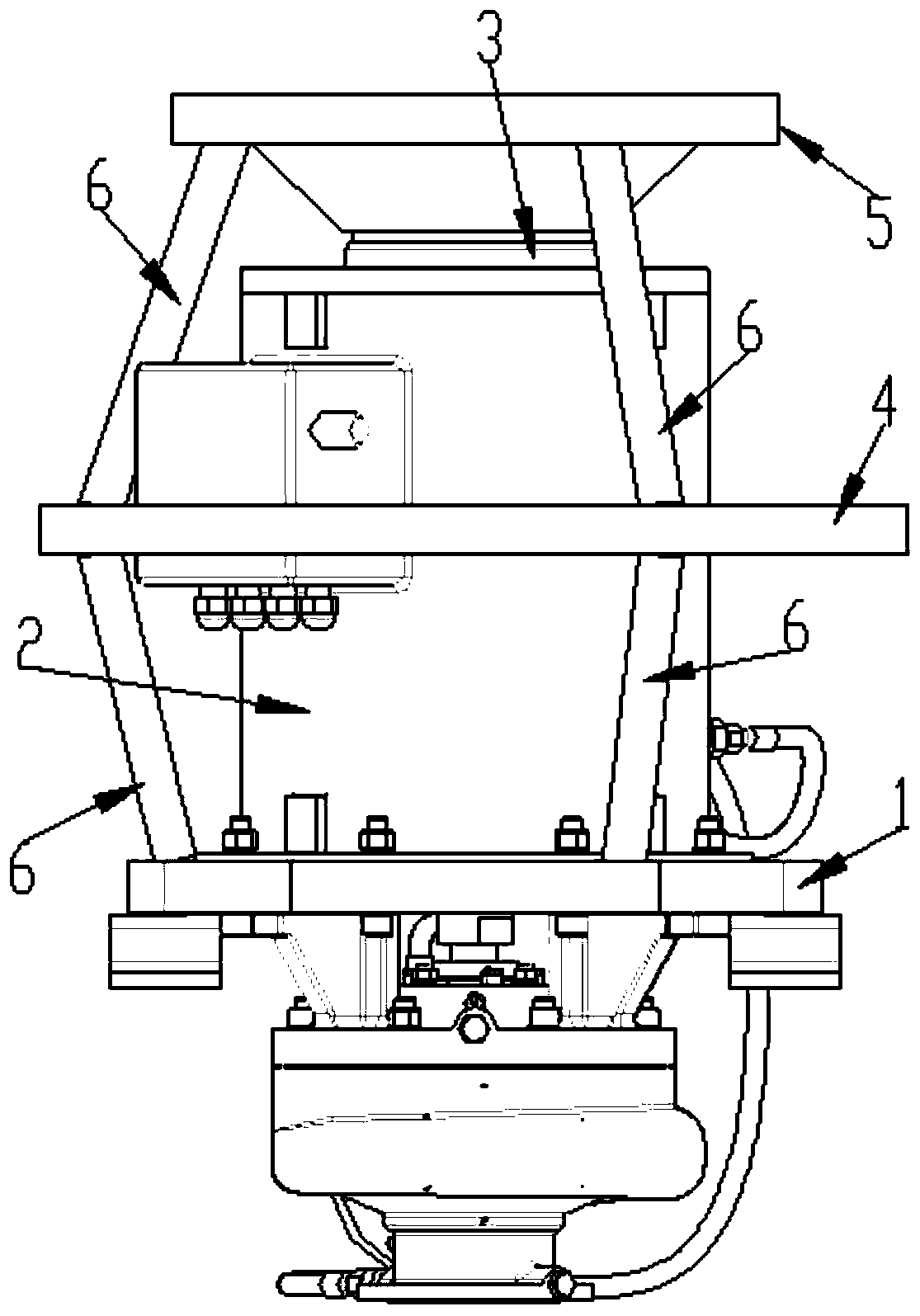

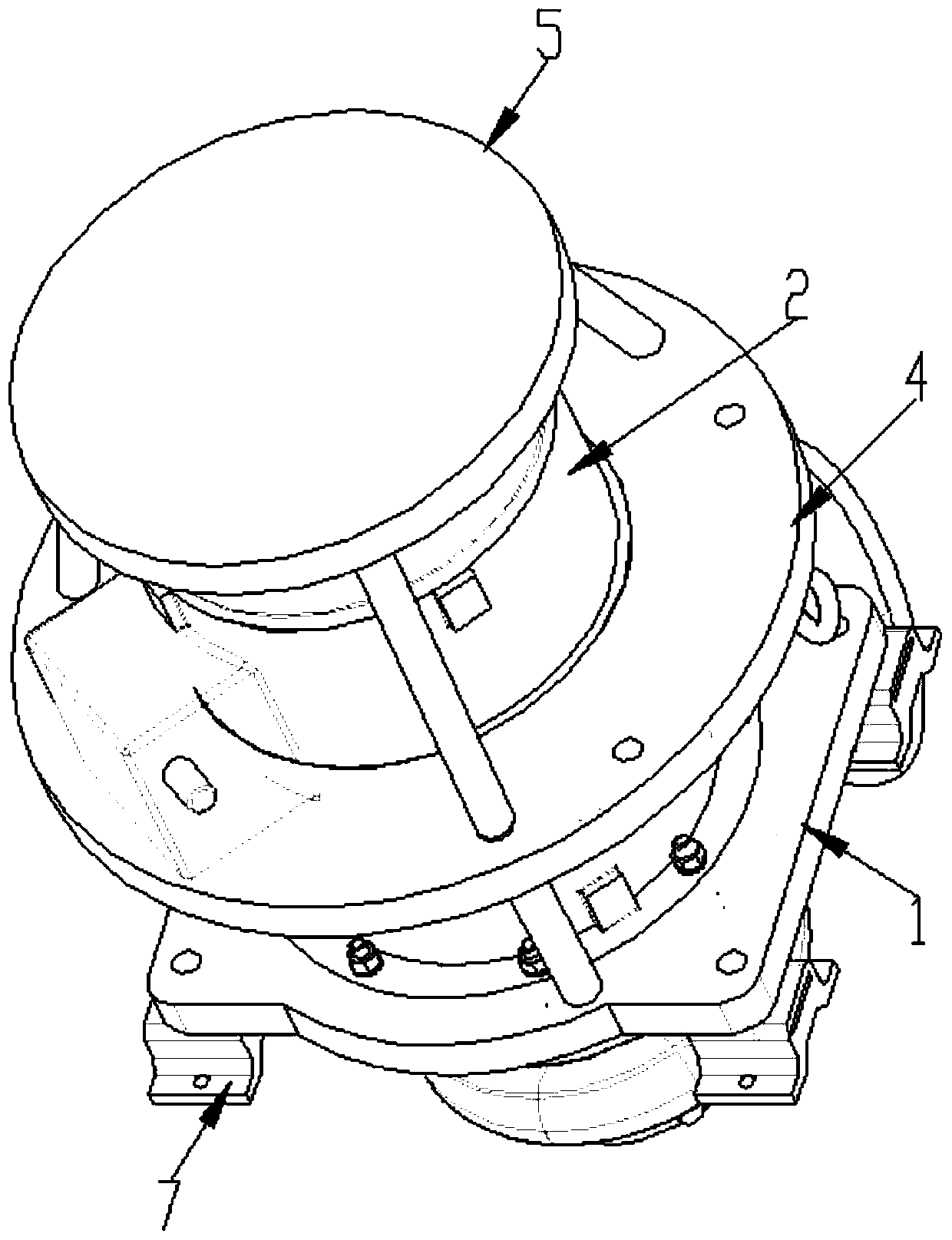

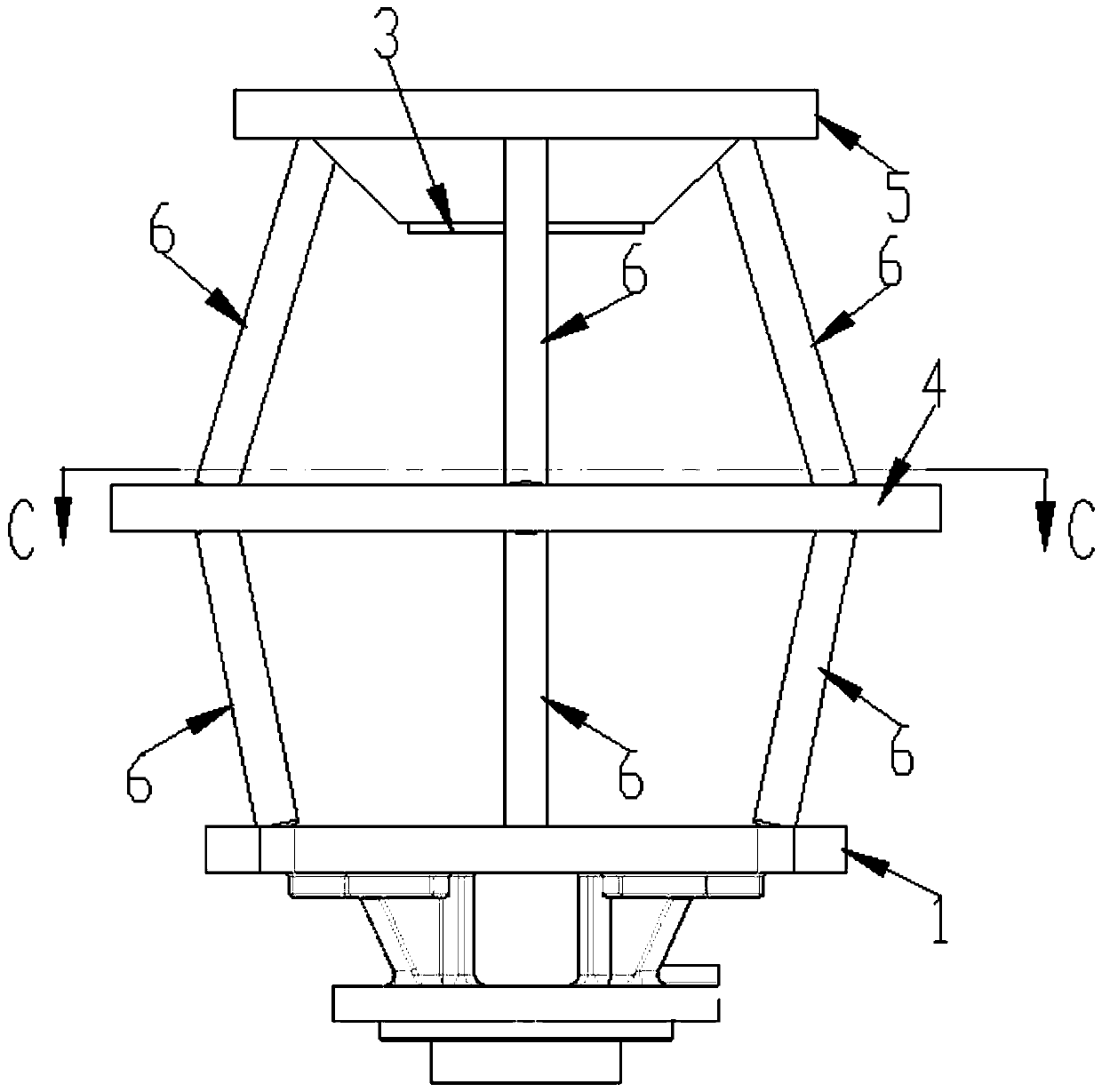

[0036] A new vibration-damping motor bracket, including a support part 1 and a vibration-damping part, the support part 1 is connected to the motor 2 and the support part 1 is used to fix the motor 2, the motor 2 is placed upright with the output shaft of the motor facing downwards, and is sleeved on the The damping part on the motor 2 is the middle damping part 4, and the damping part arranged on the top of the motor 2 is the end damping part 5, and the number of the middle damping part 4 is one and is located in the middle area of the motor 2; The shape of the damping part 4 is an annular structure, and a damping material 3 is arranged between the middle damping part 4 and the motor 2; there is a distance between the end damping part 5 and the motor 2, and a damping material is filled between the two. Vibration material 3; the end vibration damping part 5 is pressed on the top of the motor 2; the middle vibration damping part 4 is connected with the support part 1 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com