Electric heating type energy storage furnace

An electrothermal, power supply technology, applied in electric furnace heating, furnace, furnace components, etc., can solve the problems of low utilization rate of combustion heat energy, affecting the load of power supply grid, a large number of pollutants, etc., to weaken radiation and convection heat transfer, The effect of reducing electricity consumption and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

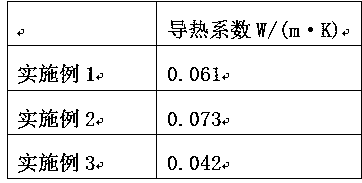

Embodiment 1

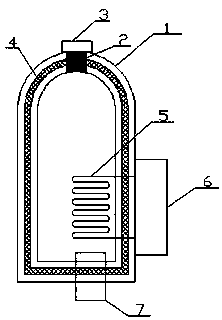

[0014] An electric energy storage furnace, characterized in that it includes: a shell 1, a liquid inlet 2, an end cover 3, an insulation layer 4, a heating wire 5, a power supply 6, and a heat exchanger 7; the liquid inlet 2 is arranged on On the top of the shell 1, the liquid inlet 2 is provided with an end cover 3, the heat insulation layer 4 is set inside the wall of the shell 1, the heating wire 5 is set inside the shell 1, and the power supply 6 is set on the right side of the shell 1 as described above. The power supply 6 is connected to the heating wire 5, and the heat exchanger 7 is arranged at the bottom of the shell 1; the heating wire is an electric heating wire;

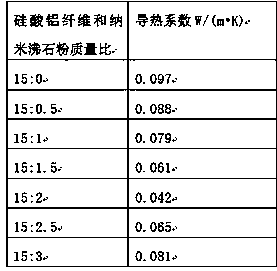

[0015] The insulation layer is made of foam insulation material; the preparation method of the insulation material comprises the following steps:

[0016] (1) First, add deionized water and absolute ethanol to the reaction kettle in sequence, then add water glass under stirring conditions, continue stirri...

Embodiment 2

[0020] An electric energy storage furnace, characterized in that it includes: a shell 1, a liquid inlet 2, an end cover 3, an insulation layer 4, a heating wire 5, a power supply 6, and a heat exchanger 7; the liquid inlet 2 is arranged on On the top of the shell 1, the liquid inlet 2 is provided with an end cover 3, the heat insulation layer 4 is set inside the wall of the shell 1, the heating wire 5 is set inside the shell 1, and the power supply 6 is set on the right side of the shell 1 as described above. The power supply 6 is connected to the heating wire 5, and the heat exchanger 7 is arranged at the bottom of the shell 1; the heating wire is an electric heating wire;

[0021] The insulation layer is made of foam insulation material; the preparation method of the insulation material comprises the following steps:

[0022] (1) First, add deionized water and absolute ethanol to the reaction kettle in sequence, then add water glass under stirring conditions, continue stirri...

Embodiment 3

[0026] An electric energy storage furnace, characterized in that it includes: a shell 1, a liquid inlet 2, an end cover 3, an insulation layer 4, a heating wire 5, a power supply 6, and a heat exchanger 7; the liquid inlet 2 is arranged on On the top of the shell 1, the liquid inlet 2 is provided with an end cover 3, the heat insulation layer 4 is set inside the wall of the shell 1, the heating wire 5 is set inside the shell 1, and the power supply 6 is set on the right side of the shell 1 as described above. The power supply 6 is connected to the heating wire 5, and the heat exchanger 7 is arranged at the bottom of the shell 1; the heating wire is an electric heating wire;

[0027] The insulation layer is made of foam insulation material; the preparation method of the insulation material comprises the following steps:

[0028] (1) First, add deionized water and absolute ethanol to the reaction kettle in sequence, then add water glass under stirring conditions, continue stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com