Construction structure and method of large-section steel-reinforced concrete column and beam node

A technology of concrete columns and large sections, which is applied in building structures, buildings, etc., can solve the problem that the construction method of beam-column joints cannot meet the requirements of on-site construction, it is difficult to confirm the slot position of the steel-framed column in advance, and the two ends of the steel bars are difficult to connect with the beams and steel bars. For such problems, the effect of solving the quality problem of concrete pouring, increasing the abundant space and not easy to waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

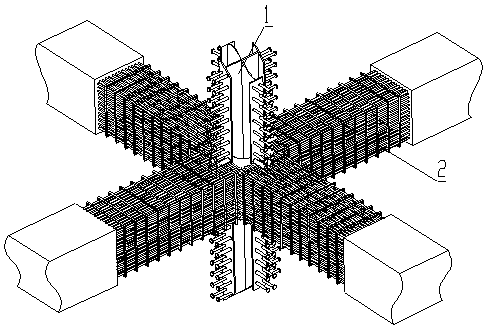

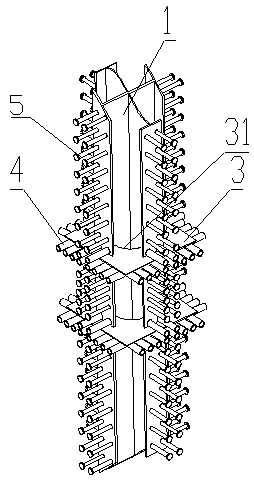

[0035] see figure 1 and figure 2 The present invention provides a construction structure and method at the joint between a large-section shaped steel concrete column and a beam, comprising a steel frame group 1 as the central structure of the shaped steel concrete column, and a beam reinforcement group 2 fixedly connected with the steel frame group 1, the steel frame group 1 is cross-shaped, which is formed by a fixed combination of four T-shaped steels. The web of each T-shaped steel is fixedly connected at one end away from the wing plate, and the wing plate constitutes the outer side of the steel frame group 1;

[0036] The connection between the steel frame group 1 and the beam reinforcement group 2 is handled by a welding plate 3, the welding plate 3 is arranged horizontally, and the welding plate 3 is fixedly connected with the steel frame group 1, and two welding plates 3 are arranged in parallel, corresponding to the beam steel group 2 respectively. The upper edge an...

Embodiment 2

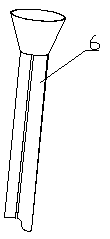

[0045] see image 3 , On the basis of Embodiment 1, this scheme provides a construction method at the joint of a large-section steel-concrete column and a beam,

[0046] S1. Prefabricate the welding plate 3 and the steel frame group 1 respectively. The steel frame group 1 is fixedly connected into a cross shape by four T-shaped steels. The upper and lower sides of the welding plate 3 are fixedly provided with a number of sleeves 4 with internal threads. Leave through hole 31;

[0047]S2. Arrange the S1 prefabricated steel frame group 1 on the installation position of the concrete column;

[0048] S3. Set the S1 prefabricated welded plate 3 on the steel frame group 1 corresponding to the position of the building beam;

[0049] S4, screw the steel bar in the sleeve 4 of the welding plate 3, and weld the steel bar with part of the steel bar of the beam steel bar group 2;

[0050] S5, welding the reinforcing bars of the steel bar group 2 corresponding to the welding plate 3 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com