A kind of antireflection, antistatic, superhydrophilic coating composition, coating and product

An anti-static and anti-reflection technology, applied in conductive coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as affecting the anti-reflection effect of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

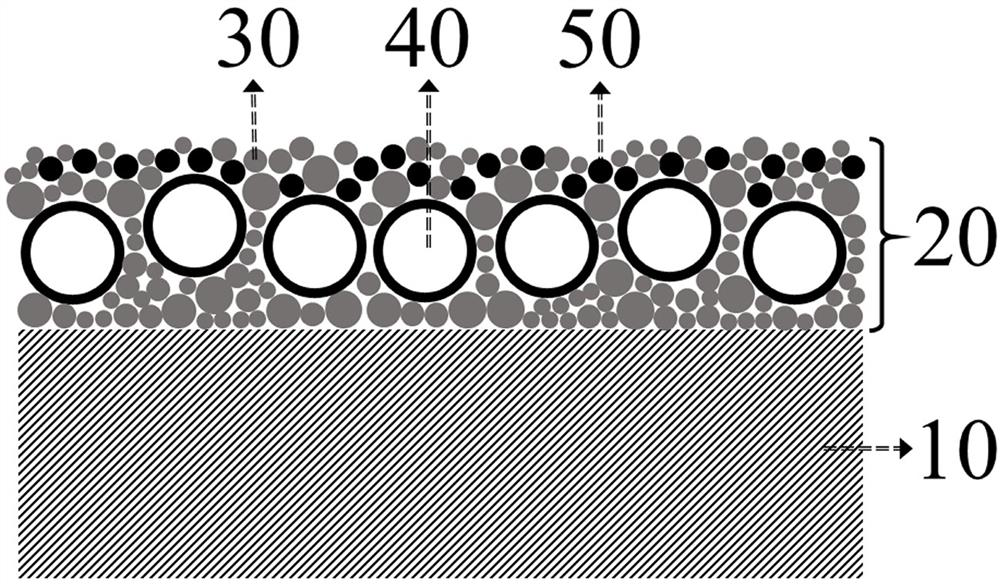

Method used

Image

Examples

Embodiment 1

[0033] Preparation of silica hollow particles.

[0034] 1) Mix 208 grams of tetraethyl silicate, 50 grams of ethanol, and 15 grams of polyethylene glycol (average molecular weight 750) until transparent, then add 15 grams of concentrated hydrochloric acid (37% by mass) and 10 grams of deionized water, after stirring for 5 minutes, heat up to 80°C to continue the reaction for 2 hours, and desolvate under reduced pressure to obtain a fluid, transparent polyalkoxysiloxane precursor with a certain viscosity; 2) Take 100 grams of polyalkoxy Add the siloxane precursor to 350 grams of deionized water and stir rapidly to obtain a white emulsion; 3) Add 25 grams of concentrated ammonia water (25% mass fraction) to the white emulsion and continue stirring for 5 hours to obtain a translucent Dispersion liquid; 4) Centrifuge the dispersion liquid to remove the supernatant liquid, wash the colloidal solid in the lower layer until the pH is less than 10, and adjust the solid content of the ...

Embodiment 2

[0037] The difference between embodiment 2 and embodiment 1 is that the amount of tetraethyl silicate in step 1) is increased to 250 grams, the amount of concentrated hydrochloric acid is reduced to 10 grams, and the amount of water is increased to 40 grams, The centrifugation-washing operation in step 4) was replaced by dialysis, and the molecular weight cut-off of the selected dialysis bag was 14000.

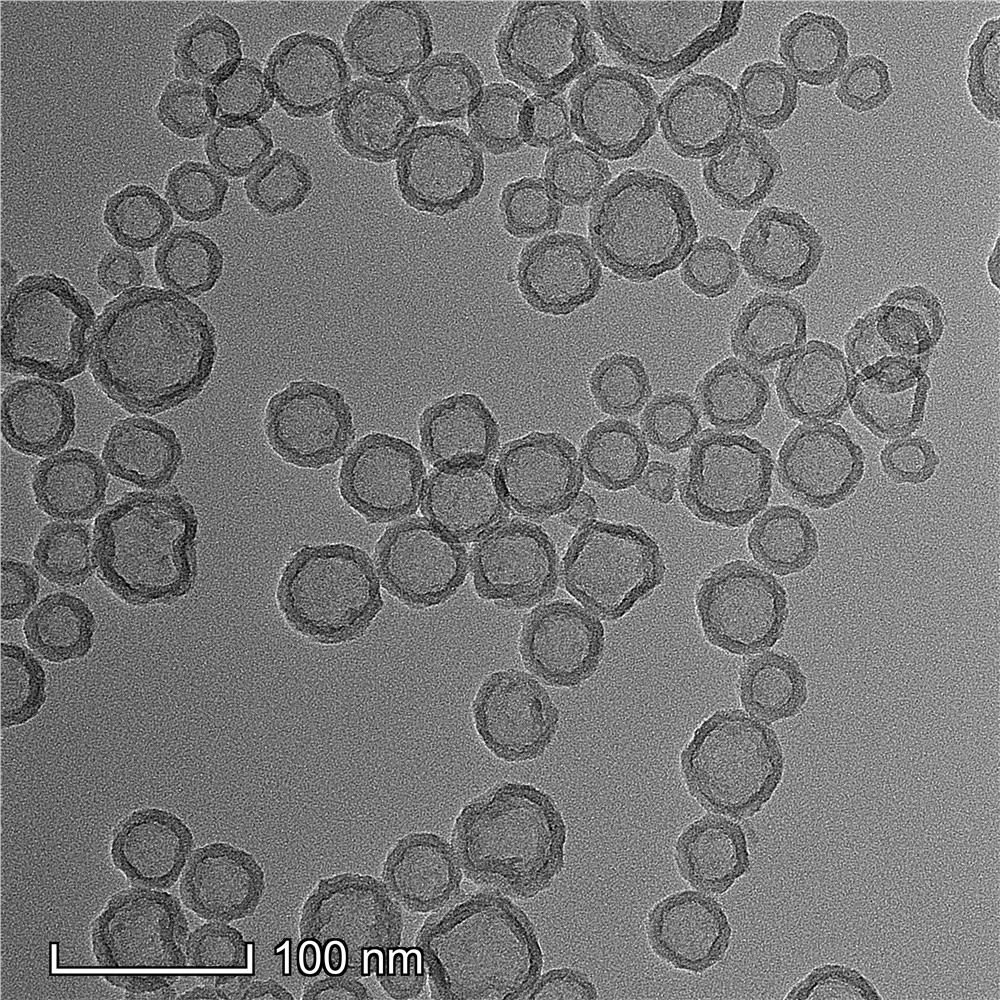

[0038] The transmission electron micrograph of gained silicon dioxide hollow particle is as follows image 3 As shown, it can be seen that the size distribution of the hollow particles is uniform, the average size is 55 nanometers, the wall thickness is 5 nanometers, the spherical structure is complete, the cavity structure is obvious, and the wall thickness is uniform.

Embodiment 3

[0040] The difference between Example 3 and Example 1 is that 208 grams of tetraethyl silicate in step 1) is replaced with 146 grams of silicon 40 commonly used in the silicone industry, and polyethylene glycol (average molecular weight 750) is replaced with For polyvinyl alcohol (average molecular weight 500), reduce the amount of concentrated hydrochloric acid and deionized water to 7.5 grams and 5 grams respectively, and replace the centrifugation-water washing operation in step 4) with ultrafiltration water washing.

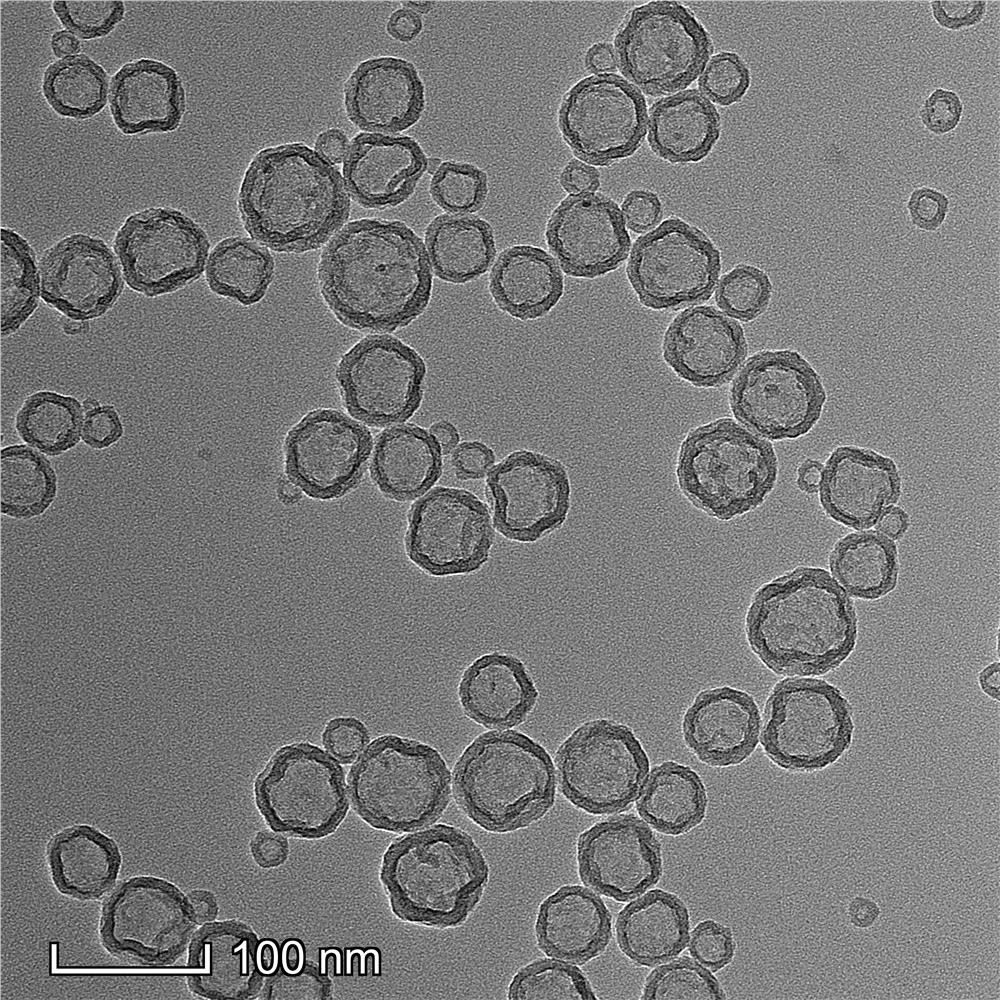

[0041] The transmission electron micrograph of gained silicon dioxide hollow particle is as follows Figure 4 As shown, it can be seen that the size distribution of the hollow particles is uniform, the average size is about 70 nanometers, the wall thickness is 6-7 nanometers, the spherical structure is complete, the cavity structure is obvious, and the wall thickness is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com