Circuit board cutting device capable of adjusting cutting position conveniently

A cutting device and circuit board technology, which is applied in metal processing and other directions, can solve the problems of reducing the cutting accuracy of circuit boards and the inability to adjust the cutting position of circuit boards, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

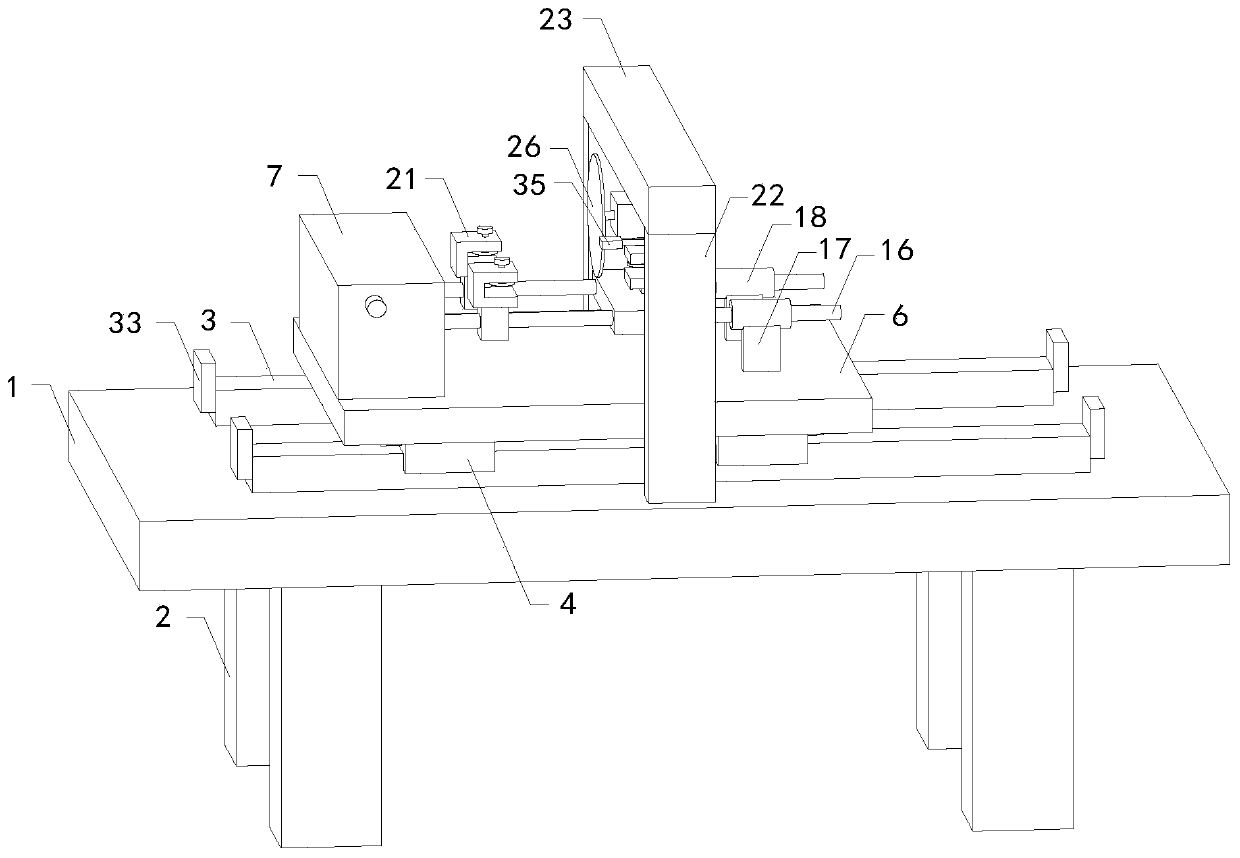

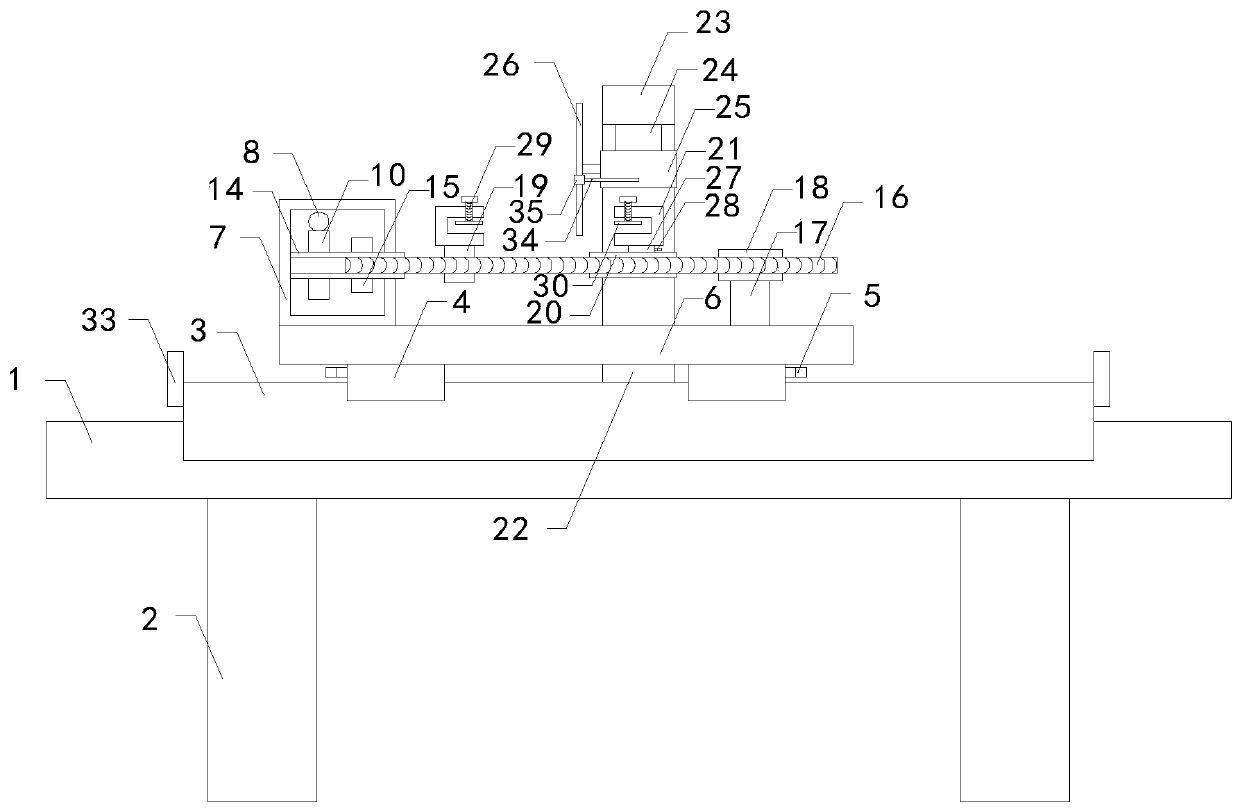

[0027] see Figure 1-2 with Figure 4-5, a circuit board cutting device for adjusting the cutting position of the present invention, comprising a workbench 1, four sets of support legs 2, two sets of adjustment guide rails 3, four sets of adjustment sliders 4, four sets of first fixing buckles 5, adjustment Plate 6, adjustment box 7, adjustment worm 8, transmission rod 9, adjustment worm wheel 10, transmission gear 11, two groups of rotating rods 12, two groups of rotating gears 13, two groups of adjusting screw pipes 14, two groups of adjusting gears 15, two groups of Adjusting threaded rods 16, two sets of support rods 17, two sets of support tubes 18, two sets of cutting tubes 19, support plates 20, three sets of fixing frames 21, two sets of columns 22, horizontal plates 23, cutting sliders 24, cutting motors 25 and cutting saw blade 26, the four sets of supporting legs 2 are respectively fixed on the left front side, right front side, left rear side and right rear side o...

Embodiment 2

[0029] see figure 1 with Figure 3-5 , a circuit board cutting device for adjusting the cutting position of the present invention, comprising a workbench 1, four sets of support legs 2, two sets of adjustment guide rails 3, four sets of adjustment sliders 4, four sets of first fixing buckles 5, adjustment Plate 6, adjustment box 7, adjustment worm 8, transmission rod 9, adjustment worm wheel 10, transmission gear 11, two groups of rotating rods 12, two groups of rotating gears 13, two groups of adjusting screw pipes 14, two groups of adjusting gears 15, two groups of Adjusting threaded rods 16, two sets of support rods 17, two sets of support tubes 18, two sets of cutting tubes 19, support plates 20, three sets of fixing frames 21, two sets of columns 22, horizontal plates 23, cutting sliders 24, cutting motors 25 and cutting saw blade 26, the four sets of supporting legs 2 are respectively fixed on the left front side, right front side, left rear side and right rear side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com