Shampoo preparation system

A technology for preparing a system and shampoo, which is applied in the field of shampoo preparation system, can solve the problems of insufficient stirring uniformity, difficult mixing of solvents or solutions, and time-consuming, etc., so as to improve the stirring efficiency, the uniformity and adequacy of stirring, and improve the uniformity of the stirring. Adequacy and the effect of improving stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

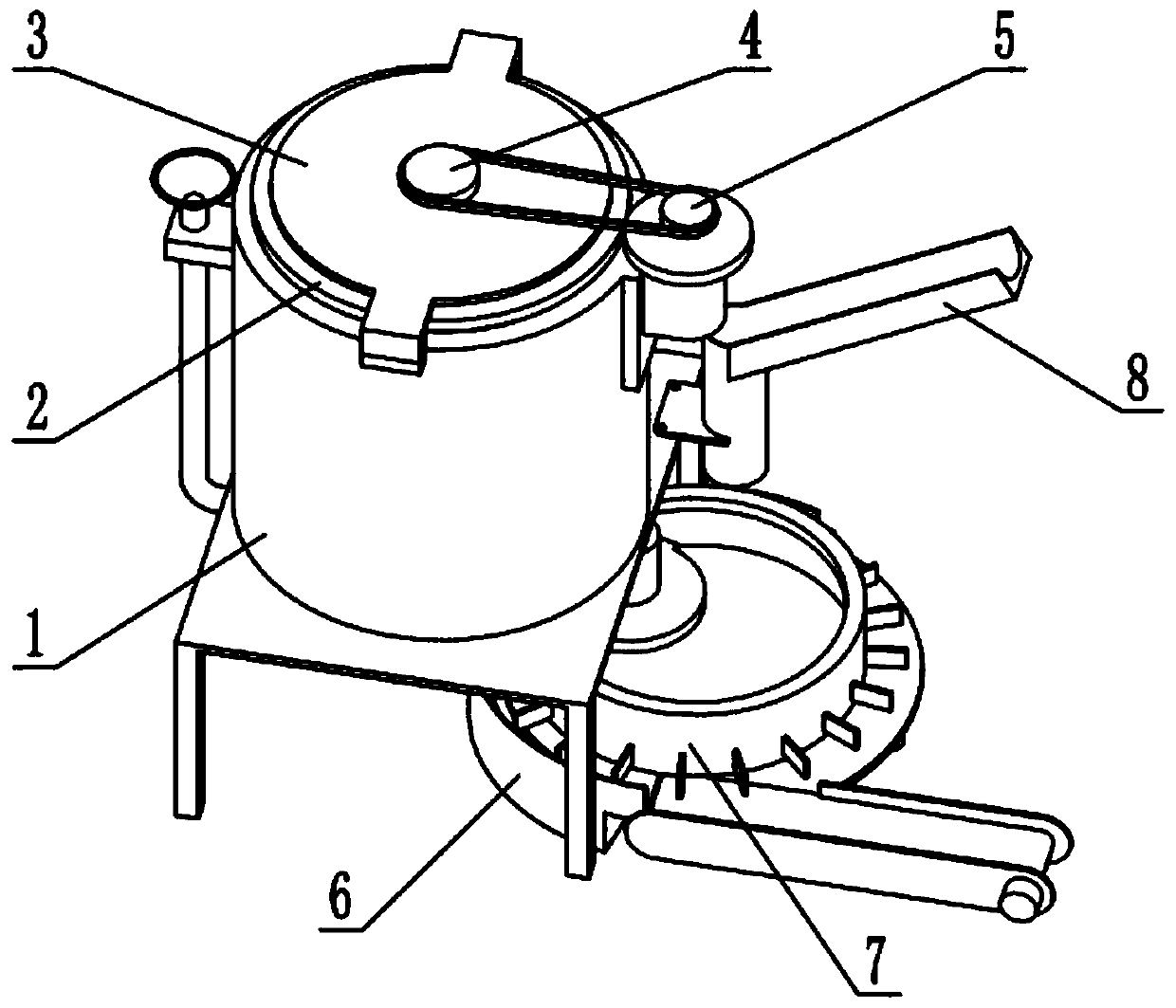

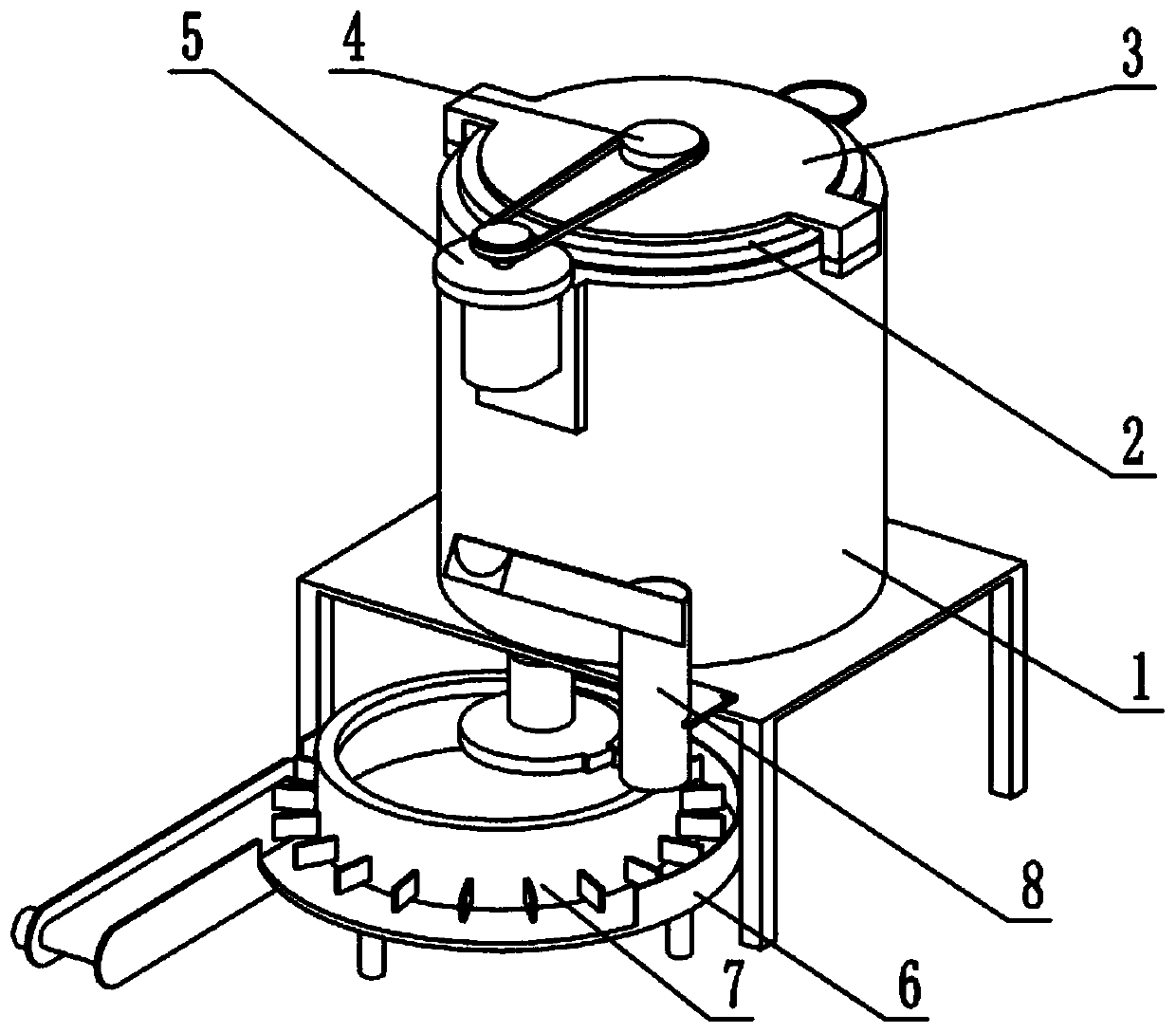

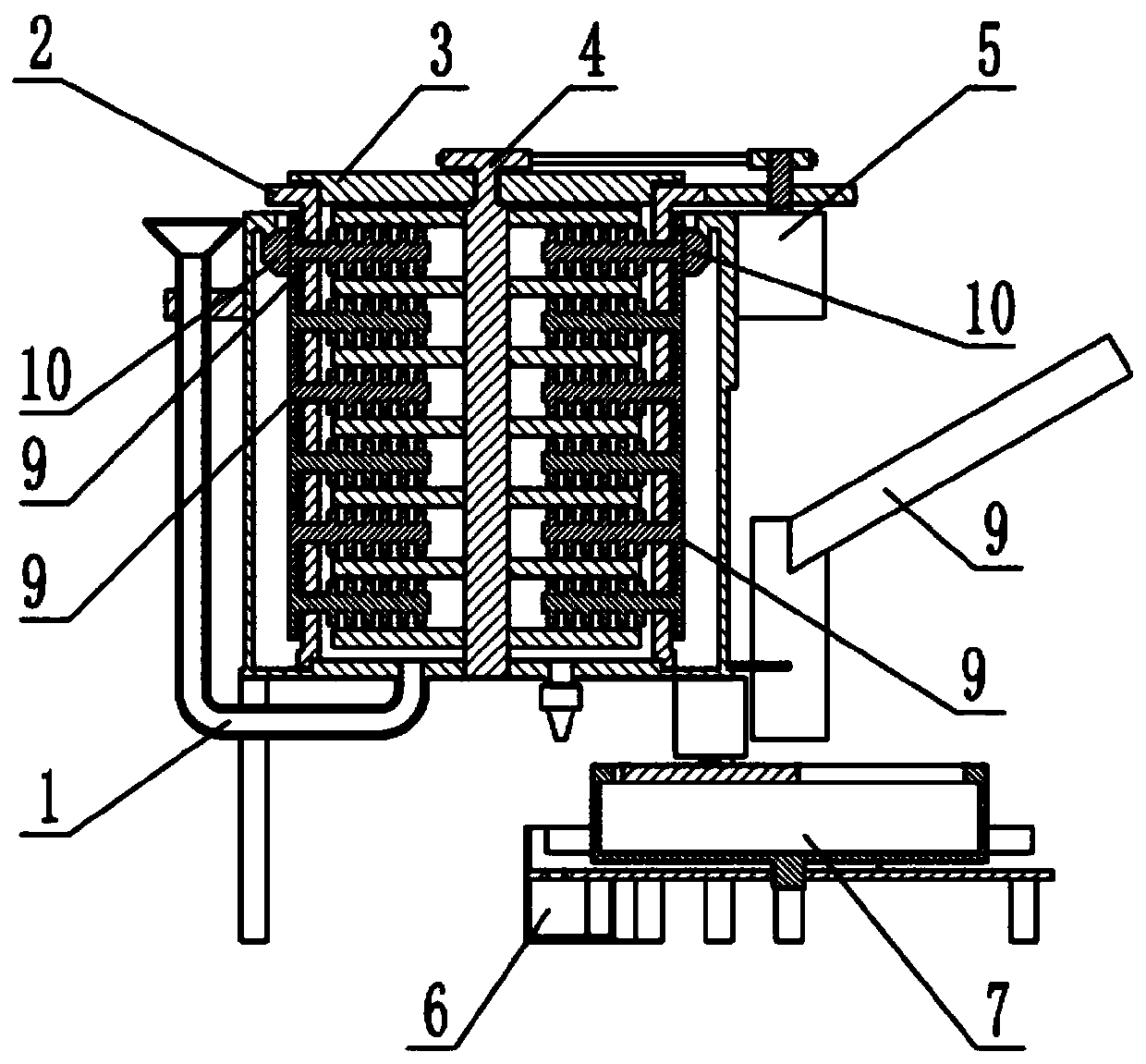

[0034] Such as Figure 1-15 As shown, a shampoo preparation system includes a main frame 1, an inner drum 2, an upper cover 3, a stirring mechanism I4, a power unit 5, a carrying and conveying mechanism 6, an intermittent bottle shifting mechanism 7, a bottle continuing device 8, and a stirring mechanism II9 and transmission bevel gear 10, the inner drum 2 is rotatably connected in the main frame 1, the upper cover 3 is fixedly connected to the upper end of the main frame 1 and is rotatably connected to the upper end of the inner drum 2, and the stirring mechanism I4 is rotatably connected to the upper cover 3, the power unit 5 is fixedly connected to the main frame 1, the inner drum 2 and the stirring mechanism I4 are both connected to the power unit 5, and the carrying and conveying mechanism 6 is located below the main frame 1, The intermittent bottle-moving mechanism 7 is rotatably connected to the carrying conveying mechanism 6, the bottle-continuing device 8 is fixedly c...

specific Embodiment approach 2

[0037] Such as Figure 1-15 As shown, the main frame 1 includes a support frame 1-1, an outer cylinder 1-2, an ear plate 1-3, an inner bevel gear 1-4, a feeding pipe 1-5, a feeding pipe fixing plate 1-6, a round table 1-7 and the discharge pipe 1-8, the lower end of the outer cylinder 1-2 is fixedly connected on the support frame 1-1, the round platform 1-7 is arranged on the support frame 1-1 and is located in the outer cylinder 1-2, and the inner The bevel gear 1-4 is fixedly connected to the upper end of the outer cylinder 1-2, and the outer side of the upper end of the outer cylinder 1-2 is fixedly connected with two ear plates 1-3, and the lower end of the feeding pipe 1-5 is fixedly connected to the support frame 1-1. At the lower end, the feeding pipe fixing plate 1-6 is fixedly connected to the outer cylinder 1-2, the feeding pipe 1-5 is fixedly connected to the feeding pipe fixing plate 1-6, and the discharge pipe 1-8 is fixedly connected to the lower end of the suppo...

specific Embodiment approach 3

[0040] Such as Figure 1-15 As shown, the inner drum 2 includes a drum 2-1, a drum gear 2-2, a fixed seat 2-3 and a rotating ring 2-4, and the drum gear 2-2 is fixedly connected to the drum 2-1. The upper end of the rotating drum 2-4 is fixedly connected to the lower end of the rotating drum 2-1, four fixing seats 2-3 are provided, and the four fixing seats 2-3 are evenly arranged on the outer end of the rotating drum 2-1 circumferentially. The rotating ring 2-4 is rotatably connected to the round table 1-7 through the seal ring and the bearing seal;

[0041] Rotary drum 2-1 is used to contain mixed liquid, drum gear 2-2 is used to cooperate with power unit 5 to rotate, fixed seat 2-3 is used to install stirring mechanism II 9, and rotating ring 2-4 is used to rotate on round table 1- 7 upper seal rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com