Eccentric shaft driving mechanism and variable compression ratio mechanism

A drive mechanism and eccentric shaft technology, which is applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of large size of the drive eccentric shaft, high research and development costs, and complex structure, and achieve simple structure, space saving, and meshing structure. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

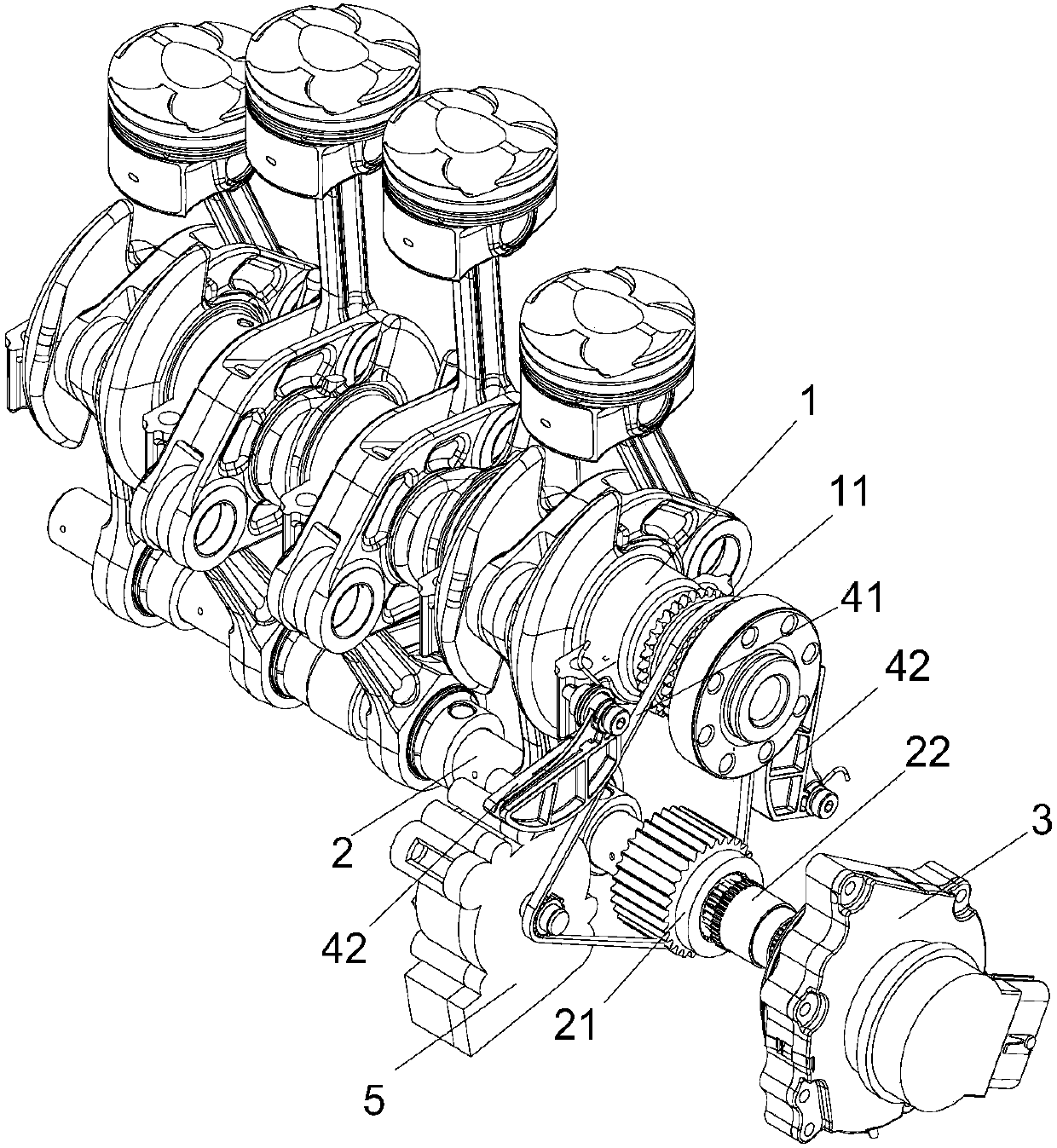

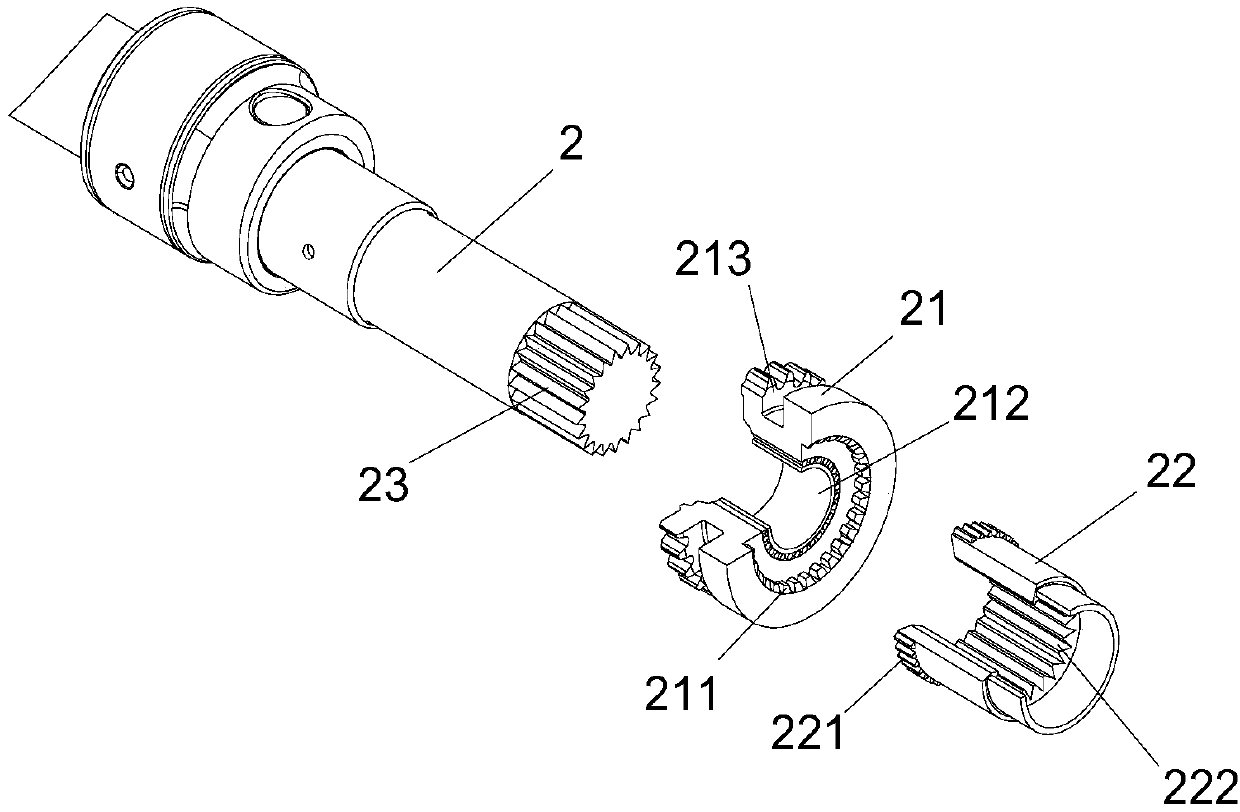

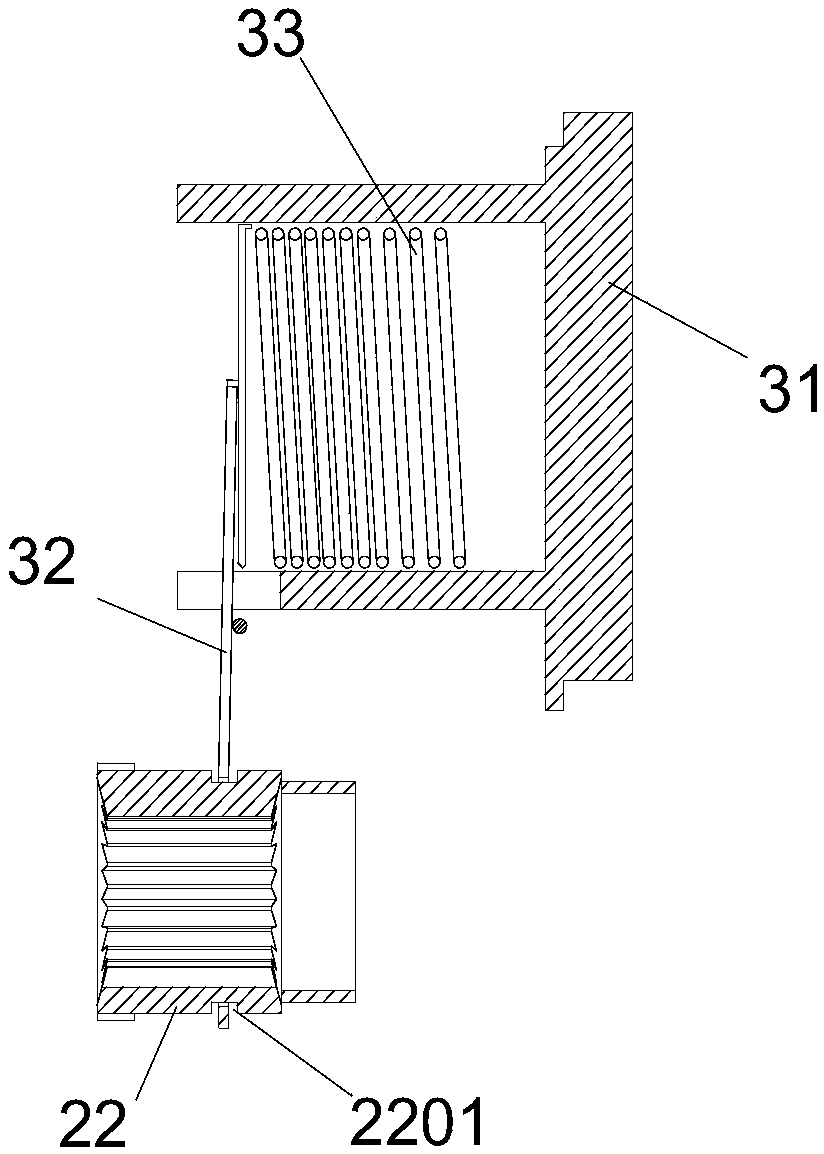

[0037] This embodiment relates to an eccentric shaft driving mechanism, which is used to receive the driving of the crankshaft 1 to drive the eccentric shaft 2 to rotate, such as Figure 1 to Figure 5 As shown, the eccentric shaft drive mechanism includes a follower 21 that is rotatably fitted on one end of the eccentric shaft 2, a transmission member 22 that is sleeved on the eccentric shaft 2 outside the follower 21, and an engine that is fixed to the eccentric shaft 2. The control part 3 on the cylinder body 62 also includes a transmission connection part provided on the transmission part 22 and the follower part 21 .

[0038] Wherein, the follower 21 forms a flexible transmission with the crankshaft 1 through the linkage 41, so that it can rotate synchronously with the crankshaft 1, and the transmission member 22 can slide axially relative to the eccentric shaft 2, and due to the eccentric shaft 2 The meshing connection of the eccentric shaft 2 is synchronously rotated. T...

Embodiment 2

[0049] This embodiment designs a variable compression ratio mechanism, which adopts a multi-link variable compression ratio mechanism, including a piston 61 slidingly arranged in the engine cylinder 62, and a crankshaft assembly arranged in the engine cylinder 62 to rotate. And the eccentric shaft assembly, and the adjusting connecting rod 63 that rotates on the crankshaft 1 in the crankshaft assembly; also includes the execution connecting rod 64 that is hinged between one end of the adjusting connecting rod 63 and the piston 61, and is hinged on the adjusting connecting rod The drive link 65 between the other end of 63 and the eccentric shaft 2 in the eccentric shaft assembly, and the eccentric shaft drive mechanism as described in Embodiment 1.

[0050] In the variable compression ratio mechanism of this embodiment, the eccentric shaft in the eccentric shaft assembly is rotated by the controller of the eccentric shaft drive mechanism as described in Embodiment 1. When the ec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com