Rapid transposition type machining jig

A fixture and fast technology, applied in the direction of manufacturing tools, worktables, etc., can solve the problems that affect the use, do not have the function of quick transposition, etc., to achieve the effect of convenient adjustment, convenient and fast transposition and fixation, and improve the accuracy of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

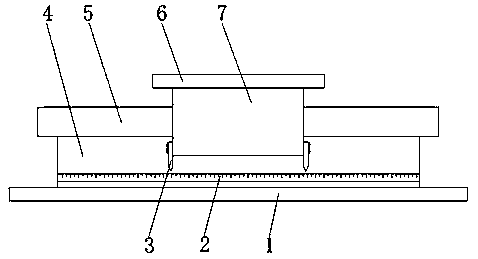

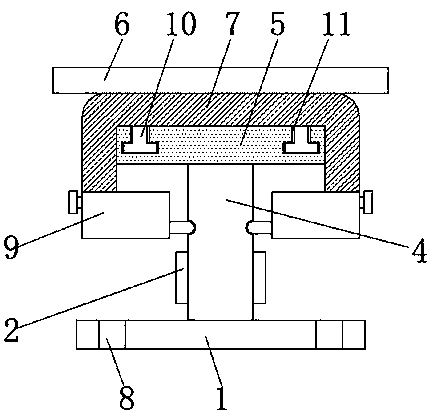

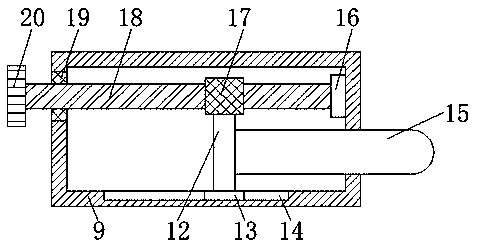

[0026] see Figure 1-3 , a fast transposition processing fixture, comprising a bottom plate 1, the top of the bottom plate 1 is fixedly connected with a fixed plate 4, the top of the fixed plate 4 is fixedly connected with a sliding plate 5, and the surface of the sliding plate 5 is covered with a sliding fixed frame 7 , the top of the sliding fixed frame 7 is fixedly connected with the jig body 6, the both sides of the top of the inner cavity of the sliding fixed frame 7 are fixedly connected with the limit slider 10, and the both sides of the surface of the sliding plate 5 are provided with a limit slider 10. Cooperate with the limit channel 11 used, both sides of the bottom of the sliding fixed frame 7 are fixedly connected with a positioning frame 9, the inner cavity of the positioning frame 9 is provided with a threaded rod 18, and the opposite side of the threaded rod 18 is movably connected with a bearing 16 , the joint between the bearing 16 and the positioning frame 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com