Multilayer interconnection FPC with rapid tin guide via hole

A via-hole, fast technology, applied in the structural connection of printed circuits, electrical connection of printed components, printed circuit components, etc., can solve the problem of pad size limitation, can not be well solved, etc., to achieve a sufficient amount of solder , to prevent virtual welding, the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

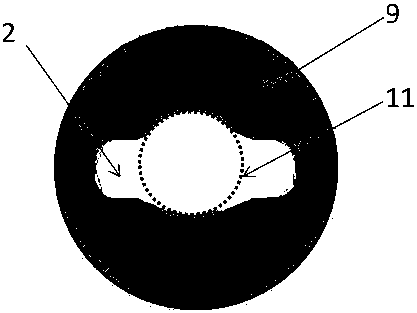

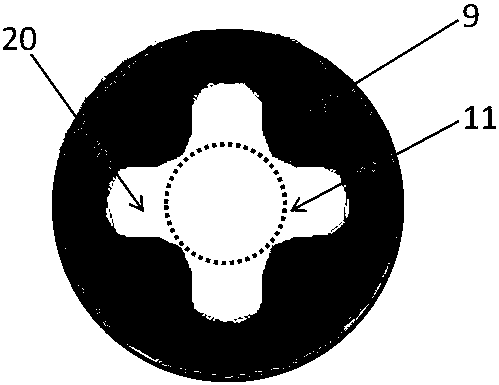

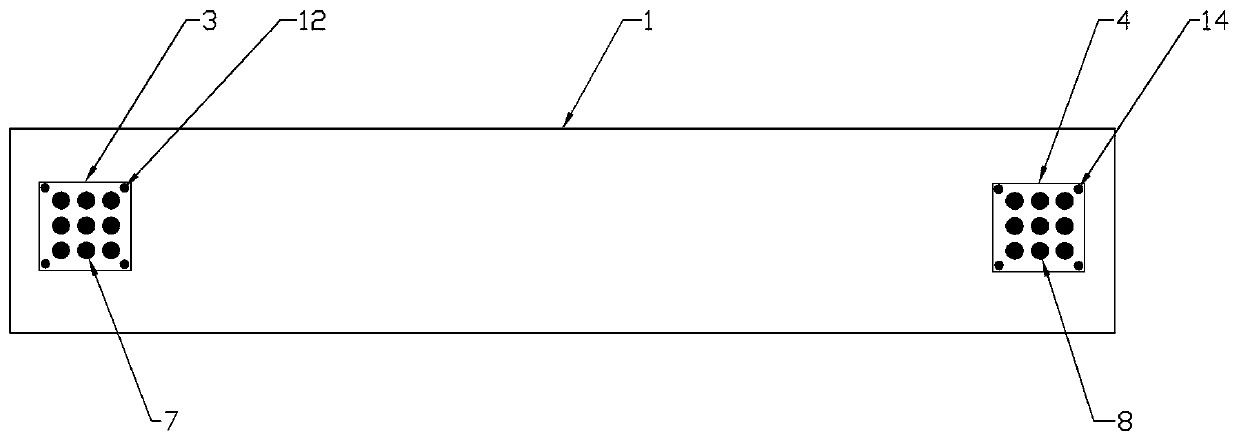

[0021] like Figure 1 to Figure 6 As shown, in this embodiment, the multi-layer interconnected FPC with fast tin-conducting vias includes a main FPC1 and an auxiliary FPC2, and the main FPC1 is provided with a main output area 3 and a main input area 4, so The auxiliary FPC2 is provided with an auxiliary output area 5 and an auxiliary input area 6; the main output area 3 is provided with several main output pads 7 connected to the main FPC1 circuit, and the main input area 4 is provided with Several main input pads 8 connected to the main FPC1 circuit, several auxiliary output pads connected to the auxiliary FPC2 circuit and corresponding to the main input pads 8 are provided in the auxiliary output area 5 The pad 9, the auxiliary input area 6 is provided with several auxiliary input pads 10 connected to the auxiliary FPC2 circuit and corresponding to the main output pad 7 one by one, the auxiliary output pad 9 and all The auxiliary input pad 10 is provided with a tin guide v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com