A method and system for controlling the lifting and lowering sequence of screeds in a gypsum board production line

A sequence control and flattening technology, which is applied in the field of gypsum board production line, can solve the problems of flattened slab stock, the edge of the slab is lifted, and the edge pressing device is damaged, so as to improve work efficiency, improve the leveling effect, and improve the production quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

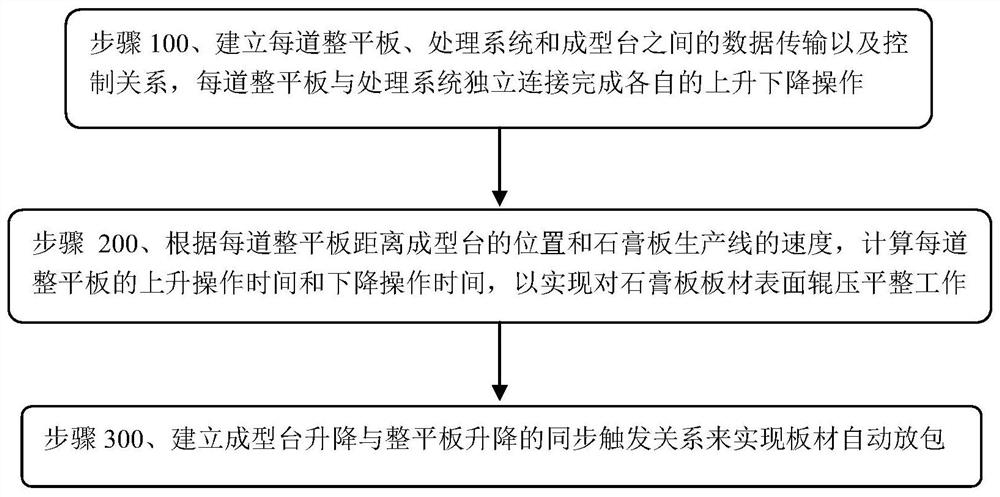

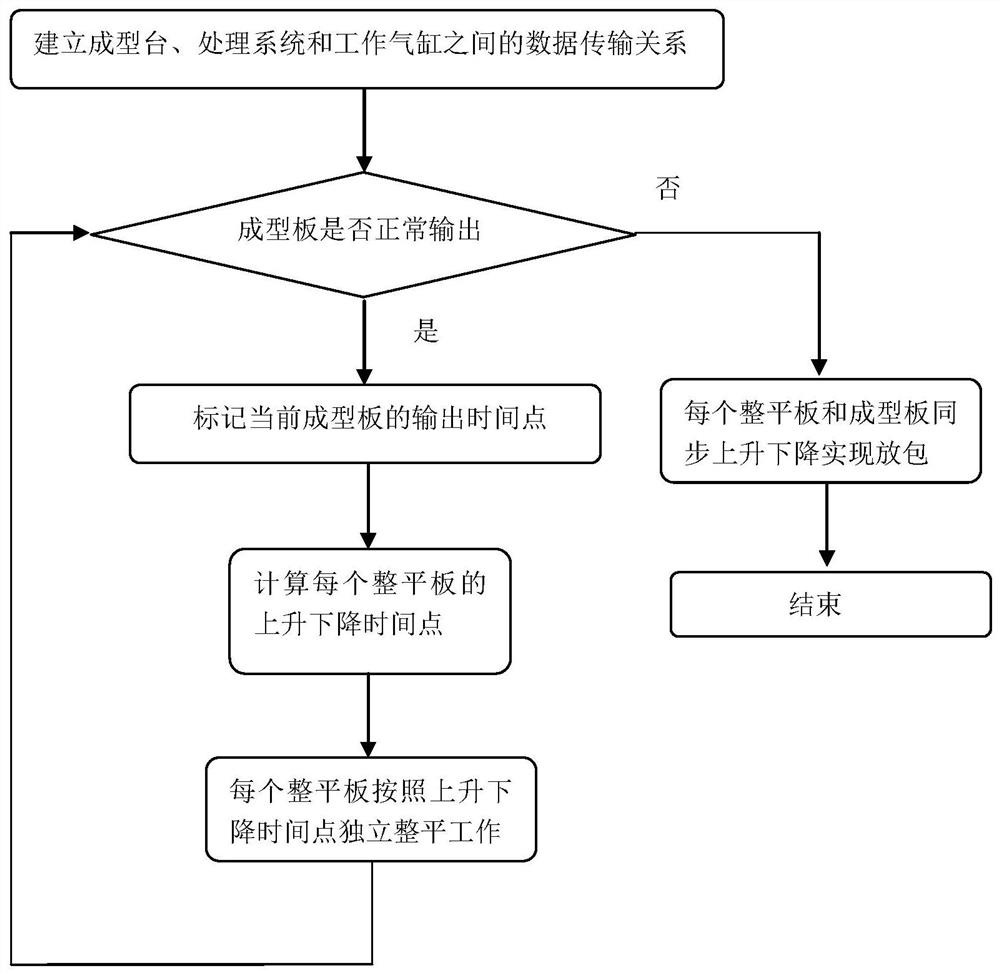

[0049] like figure 1 and figure 2 As shown, the present invention provides a method for controlling the up and down sequence of screeds in a gypsum board production line, which is different from the manual control of the up and down operation of the screeds in the prior art. In addition, this embodiment changes the rise and fall of the screeds into intelligent automation equipment, According to the distance between each screed and the start of forming plate conveying, set the rising operation time point and descending operation time point of each screed plate, and automatically control the rising and falling work of the screed plate according to the set time point, effectively solving the problem Lifting the screed too early will cause the edges of some boards to warp, and lifting the screed too late will result in material accumulation on the screed or damage to the edge-holding device, thereby improving work efficiency and improving the production quality of gypsum boards ...

Embodiment 2

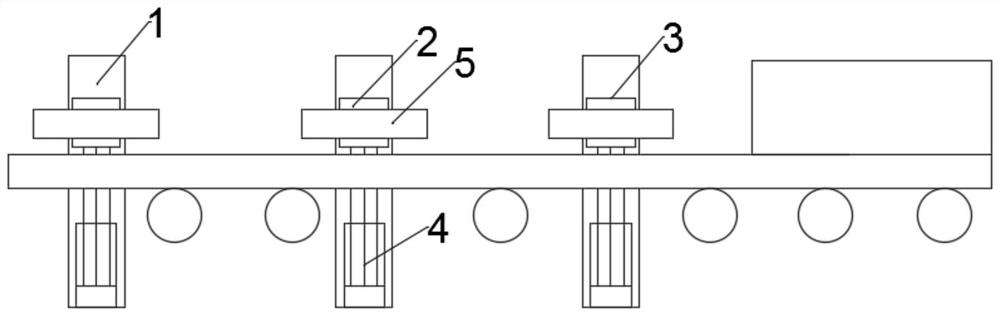

[0078] In addition if image 3 and Figure 4 As shown, the present invention also provides a gypsum board production line screed plate lifting sequence system, which specifically includes: an extrusion molding unit, an electric control unit 7, a forming table state monitoring unit 8, a processing unit 9, a timing unit 10 and a timing unit 11. The extrusion molding unit is divided into three parts: forming table, leveling plate and wedge-shaped edge chamfering, which are used to determine the thickness, width and wedge-shaped edge of the gypsum board.

[0079] The electric control unit 7 is connected with the power supply terminal of the power assembly of each screed, and is used to control the rising or falling state of each screed.

[0080] The forming table state monitoring unit 8 is used to monitor the moving state of the forming plate inside the forming table and the rising and falling state of the forming table itself, which is divided into two states: normal output of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com