A 3D printed micro implant guide plate and its design method

A technology of micro-implant nails and 3D printing, applied in the fields of implantology, medical science, dentistry, etc., can solve the problems of increased error, insufficient stability and accuracy, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

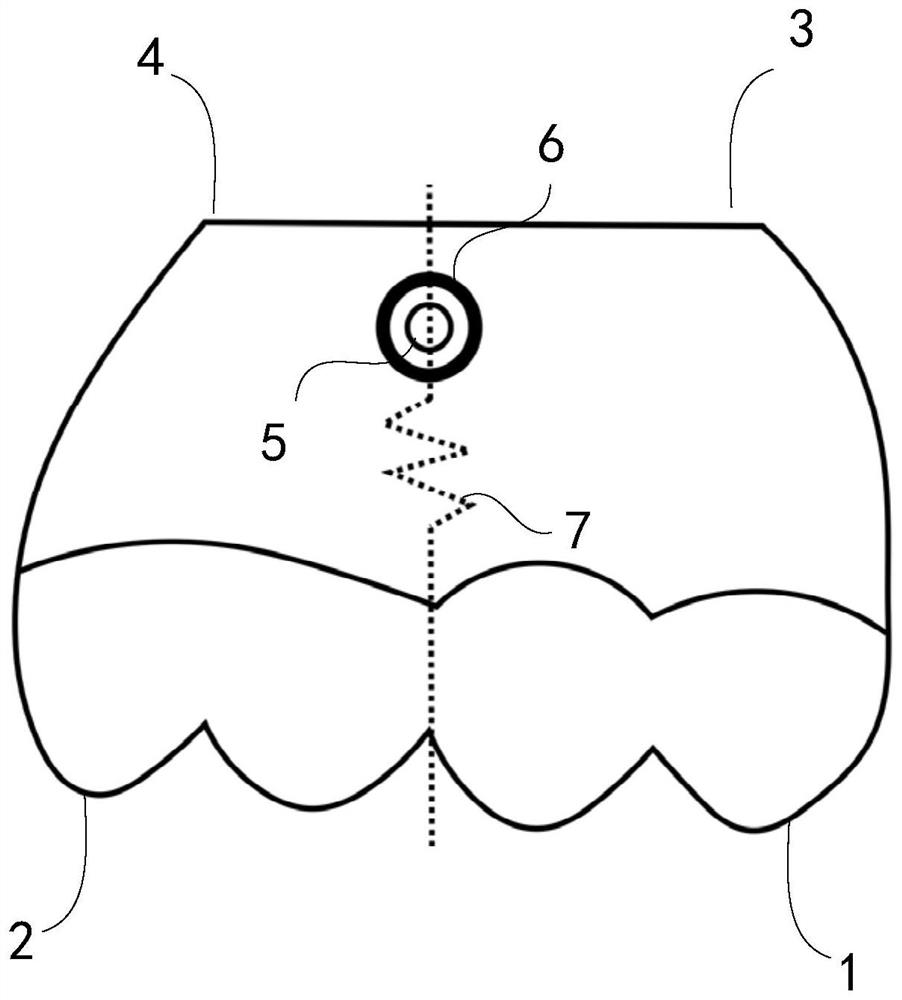

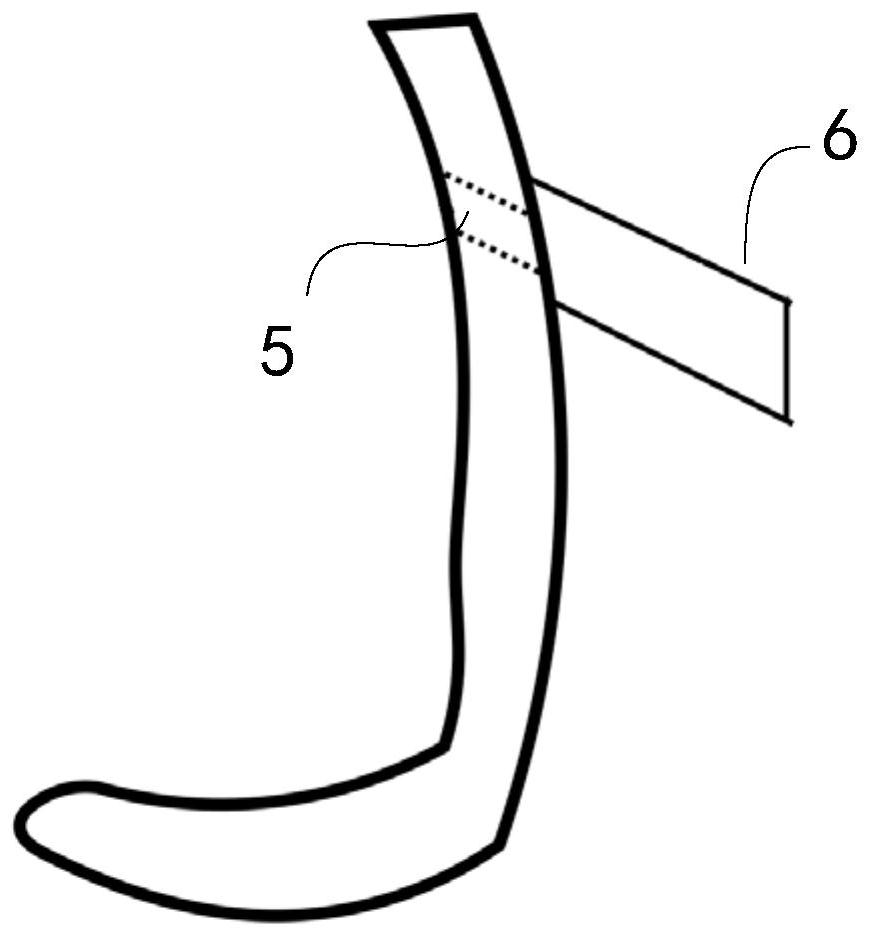

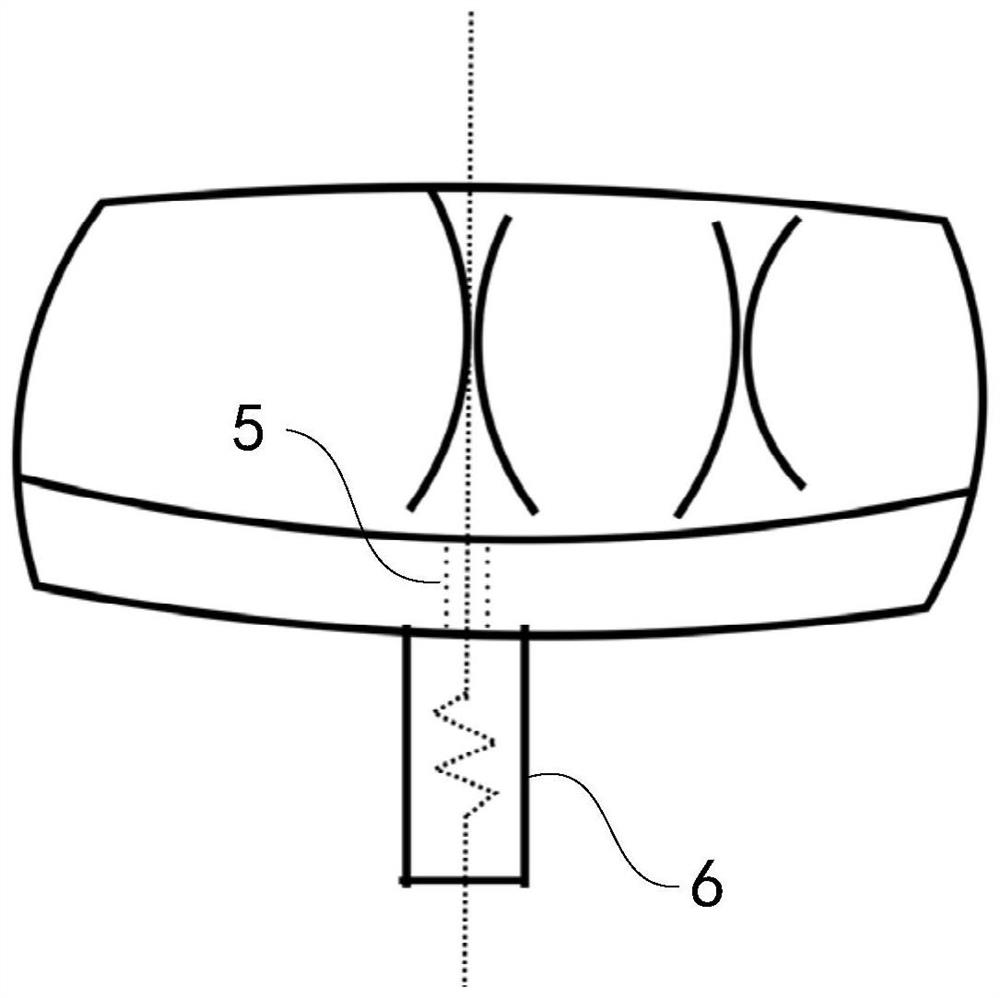

[0058] In this embodiment, it is taken as an example to plan to implant micro-screws between the maxillary first molars and the second premolars. The micro-screw guide plate includes a tooth surface retention plate, a gingiva retention plate and a micro-screw guide implantation part, with a uniform thickness of about 2-3mm. The tooth surface retention plate includes the molars and the two mesial premolars at the place where the micro-implant screws are to be implanted. When it is planned to be implanted between the maxillary first molars and the second premolars, the retention part should be the maxillary First premolars, second premolars and first molars. The gingival retaining plate includes 2-3mm from the gingival margin to the vestibular sulcus where the micro-implant is placed. The guiding part is composed of two units, one is the micro-screw insertion hole to guide the implantation site of the micro-implant, and the other is the handle guiding channel to guide the impla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com