An electronic truck scale weighing system and lightning protection method based on Internet of Things technology

An Internet of Things technology and weighing system technology, which is applied in the field of electronic truck scale weighing system and lightning protection, can solve the problems of inability to systematically connect data, inability to store data, and truck scale damage, and achieve strong anti-interference ability and confidentiality. Good sex, anti-cheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

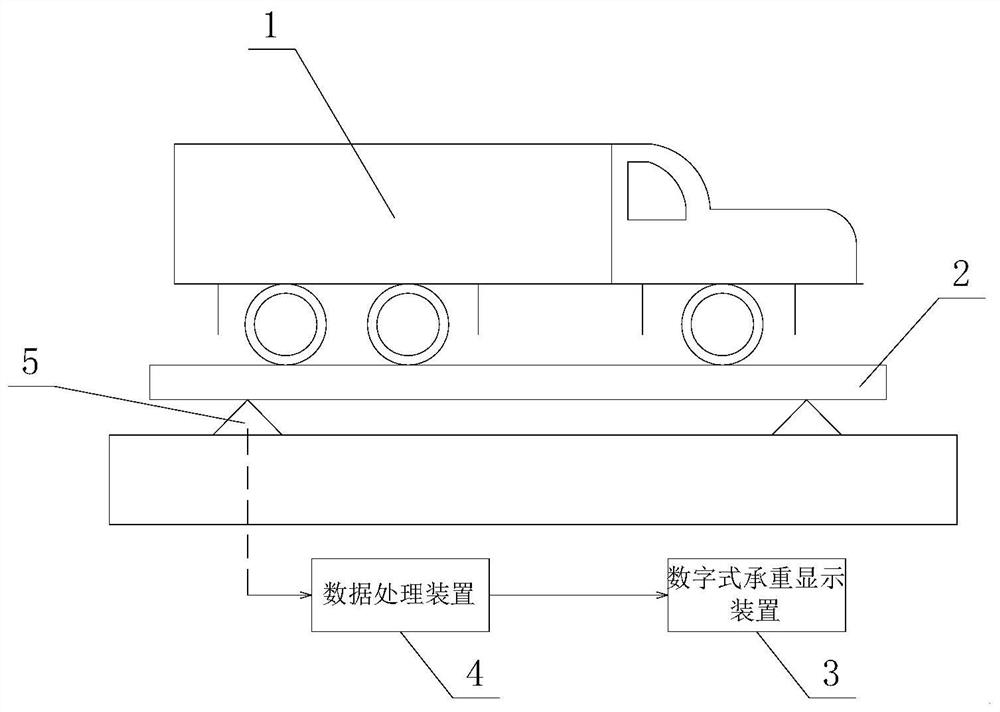

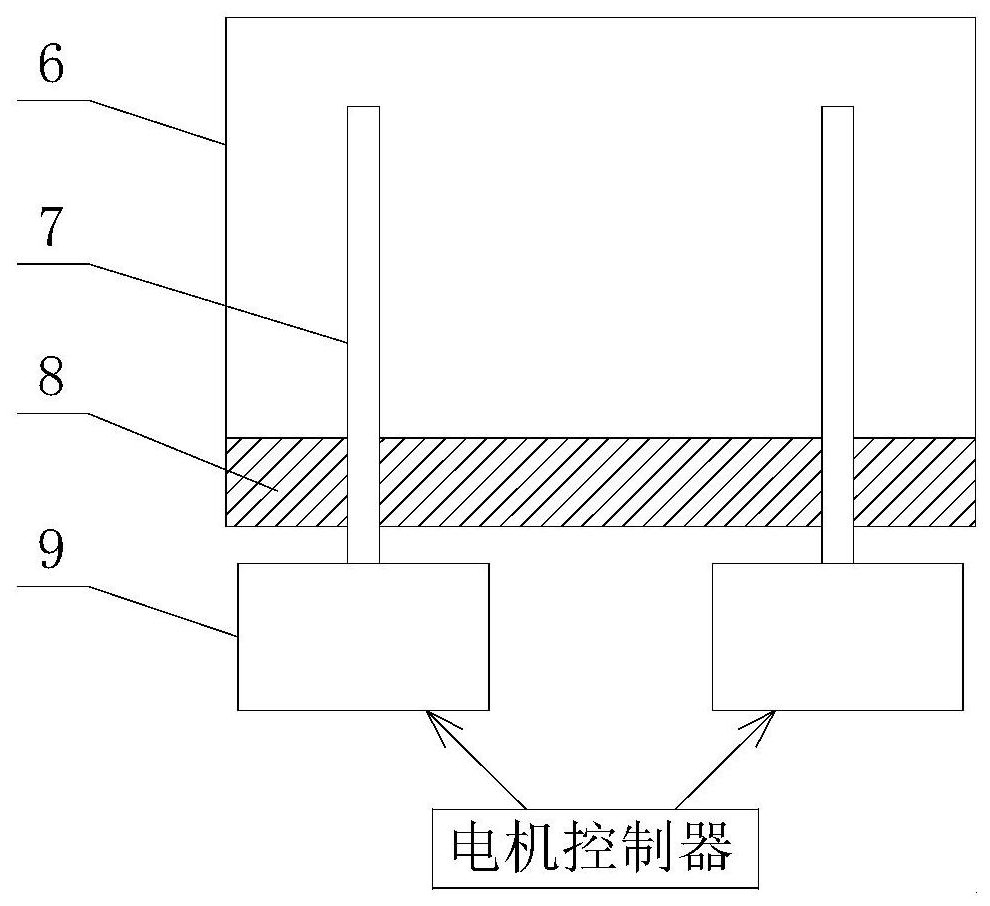

[0037] figure 1 , figure 2 , image 3 , Figure 4 Schematically shows the structure of an electronic truck scale weighing system and lightning protection method based on Internet of Things technology according to an embodiment of the present invention.

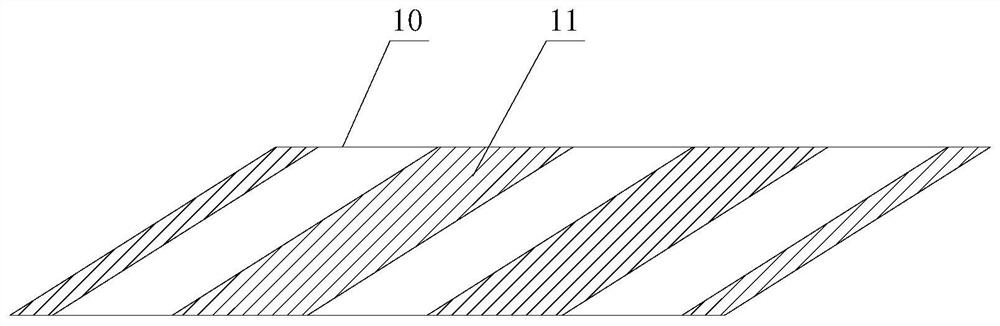

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an electronic truck scale weighing system based on Internet of Things technology is characterized in that it includes a weighing body, a weighing sensor, a data processing device and a digital load-bearing display device, and the weighing body includes a load-bearing platform and a steel plate, The load-bearing platform is a three-section all-steel frame structure, and the load-bearing platform structure is a U-shaped steel beam, and the steel plate is welded on the load-bearing platform; Overlapping, the output end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com