Shared actuator of clutch and parking mechanism

A parking mechanism and clutch technology, applied in the automotive field, can solve the problem of high power consumption of the actuator, and achieve the effects of reducing the return stroke, reducing the stroke and reducing the time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

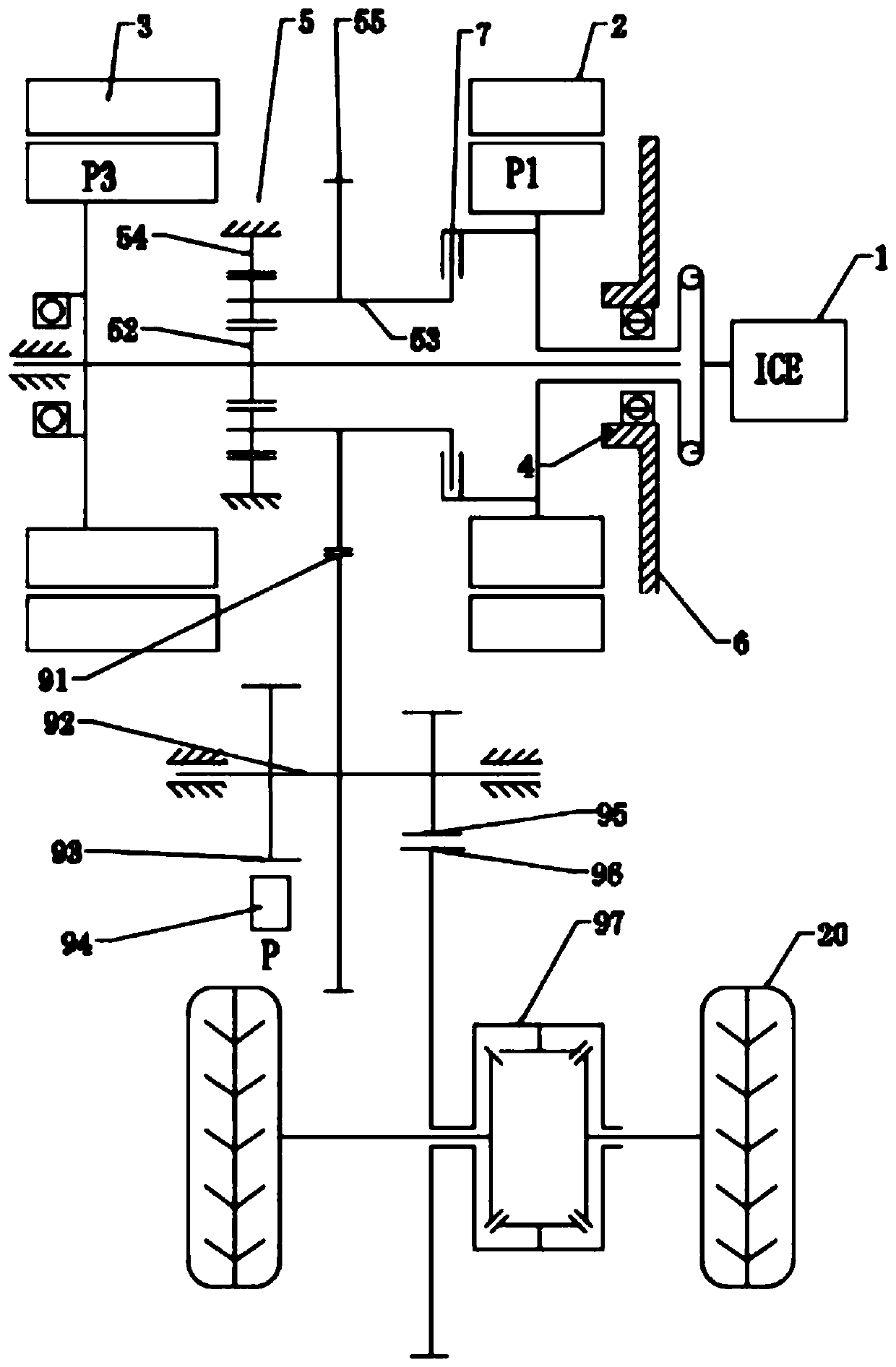

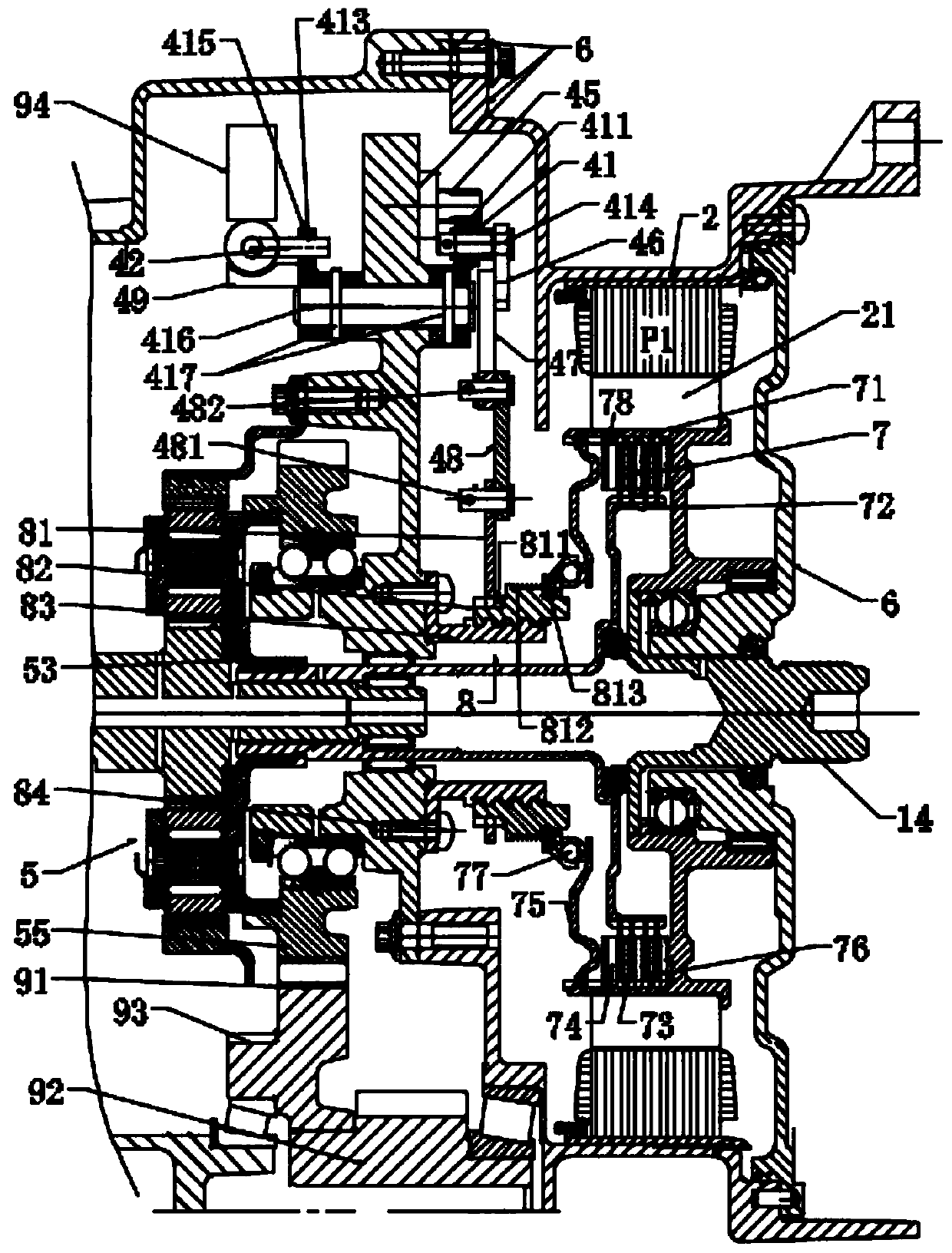

[0032] combine Figure 1 to Figure 6 , the present embodiment provides an actuator shared by a clutch and a parking mechanism, including a drive motor 45 and a gear arc 41, the drive motor 45 is provided with a drive gear 451, and the gear arc 41 is provided with a The transmission gear 411 matched with the gear 451, the drive gear 451 meshes with the transmission gear 411 so that the drive motor 45 drives the tooth arc 41 to rotate around the fixed axis 416, and the tooth arc 41 is provided with a first pin hole 413 and a second pin hole 414, the first pin hole 413 is rotatably connected with the parking actuating lever 42, the second pin hole 414 is rotatably connected with the clutch drive lever 46, and the parking actuating lever 42 is used The parking mechanism is driven under the action of the tooth arc 41 , and the clutch drive lever is used to drive the clutch 7 under the action of the tooth arc 41 . That is, the tooth arc 41 can drive the clutch 7 and the parking mec...

Embodiment 2

[0057] combine Figure 1 to Figure 6 , this specification provides a vehicle including the clutch described in Embodiment 1 and the actuator shared by the parking mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com