Stacking device for steel inspection laboratory of metallurgical enterprise

A technology of stacking device and steel wire rope, which is applied in the field of stacking device to achieve the effect of convenient charging and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

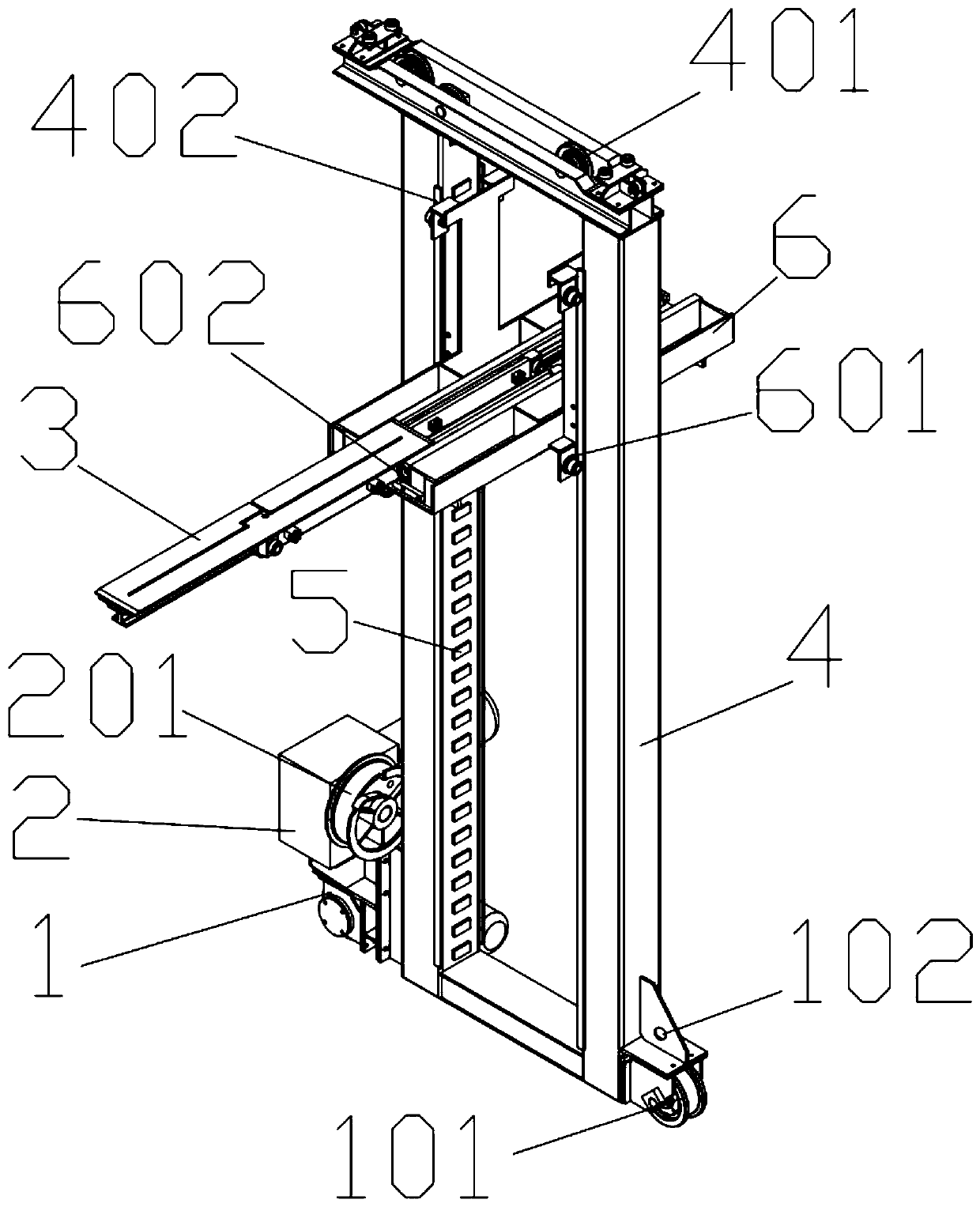

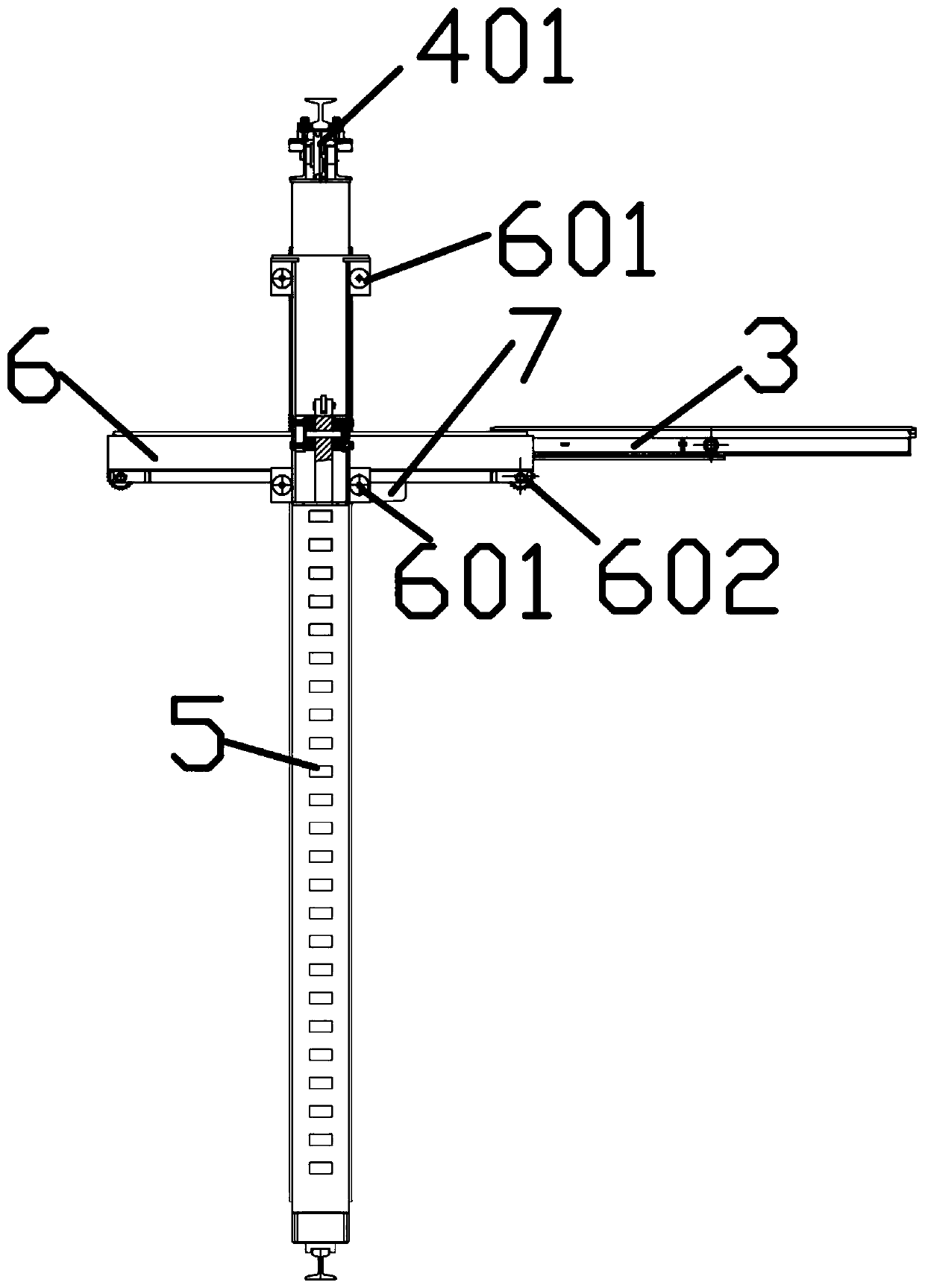

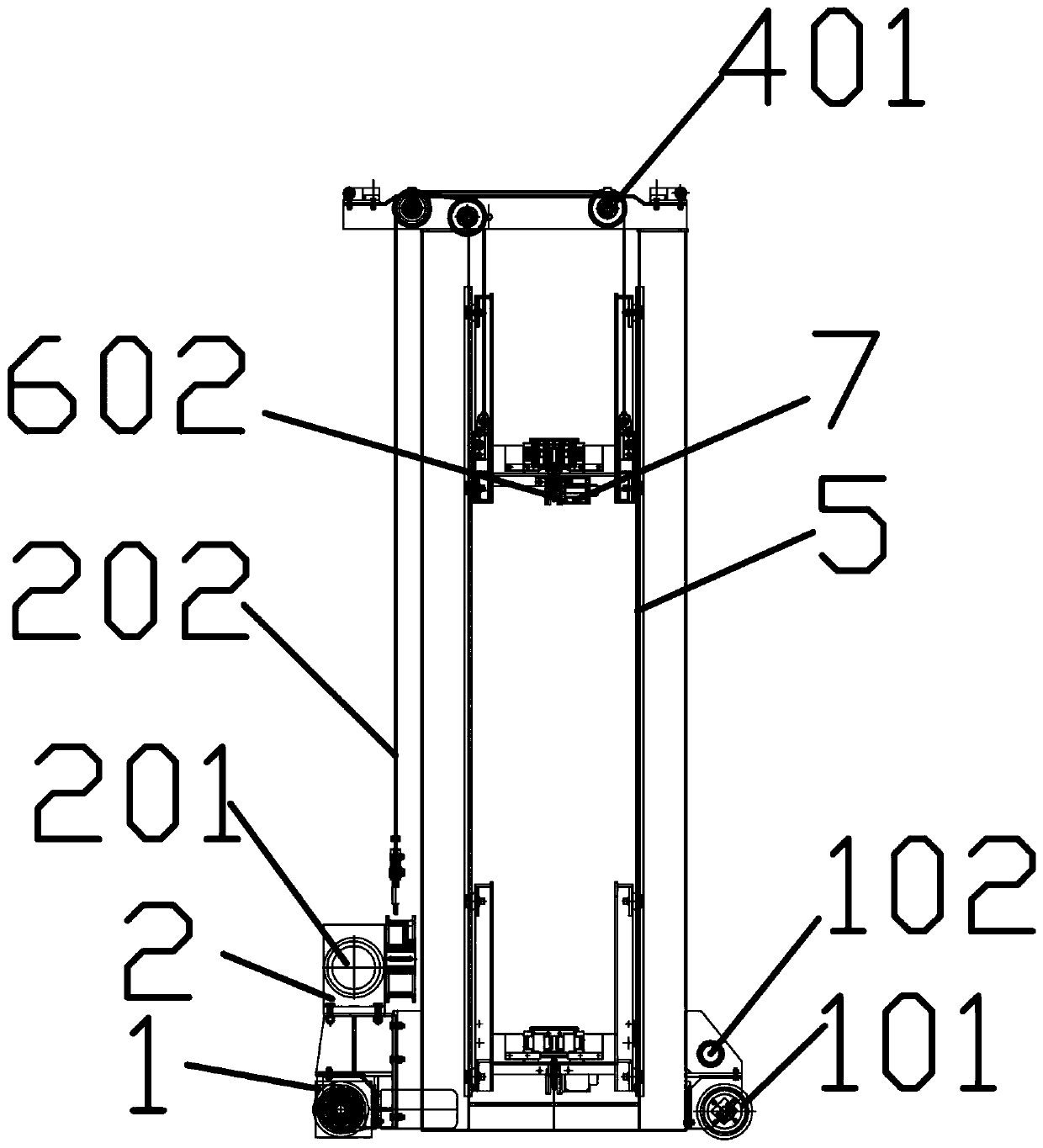

[0023] Below will combine the appended in the embodiment of the present invention Figure 1-4 The technical solutions in the embodiments of the present invention are described.

[0024] see Figures 1 to 4 , the present invention provides a technical solution: a stacking device for metallurgical enterprise iron and steel inspection and laboratory comprising: horizontal traveling mechanism 1, lifting mechanism 2, upper tray 3, door-shaped frame 4, lifting mechanism encoder 5, lower Pallet 6, motor 7, electric box 8, roller 101, hanging hole 102, reel 201, wire rope 202, fixed pulley 401, pallet 402, pallet wheel 601, gear 602, limit table 801, connecting piece 802, electric box Taiwan 803.

[0025] In the present invention, the stacking device mainly includes a horizontal walking mechanism 1, a lifting mechanism 2, an upper tray 3, a door-shaped frame 4, and a lower tray 6, and the door-shaped frame 4 is a door-shaped rectangular structure, and the lower end of the lower tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com