Wafer transmission device and method for reaction chamber

A transmission device and reaction chamber technology, which is applied in transportation and packaging, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of not being able to meet the needs of 12-inch and above wafers, increase debugging costs, and improve transmission stability , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

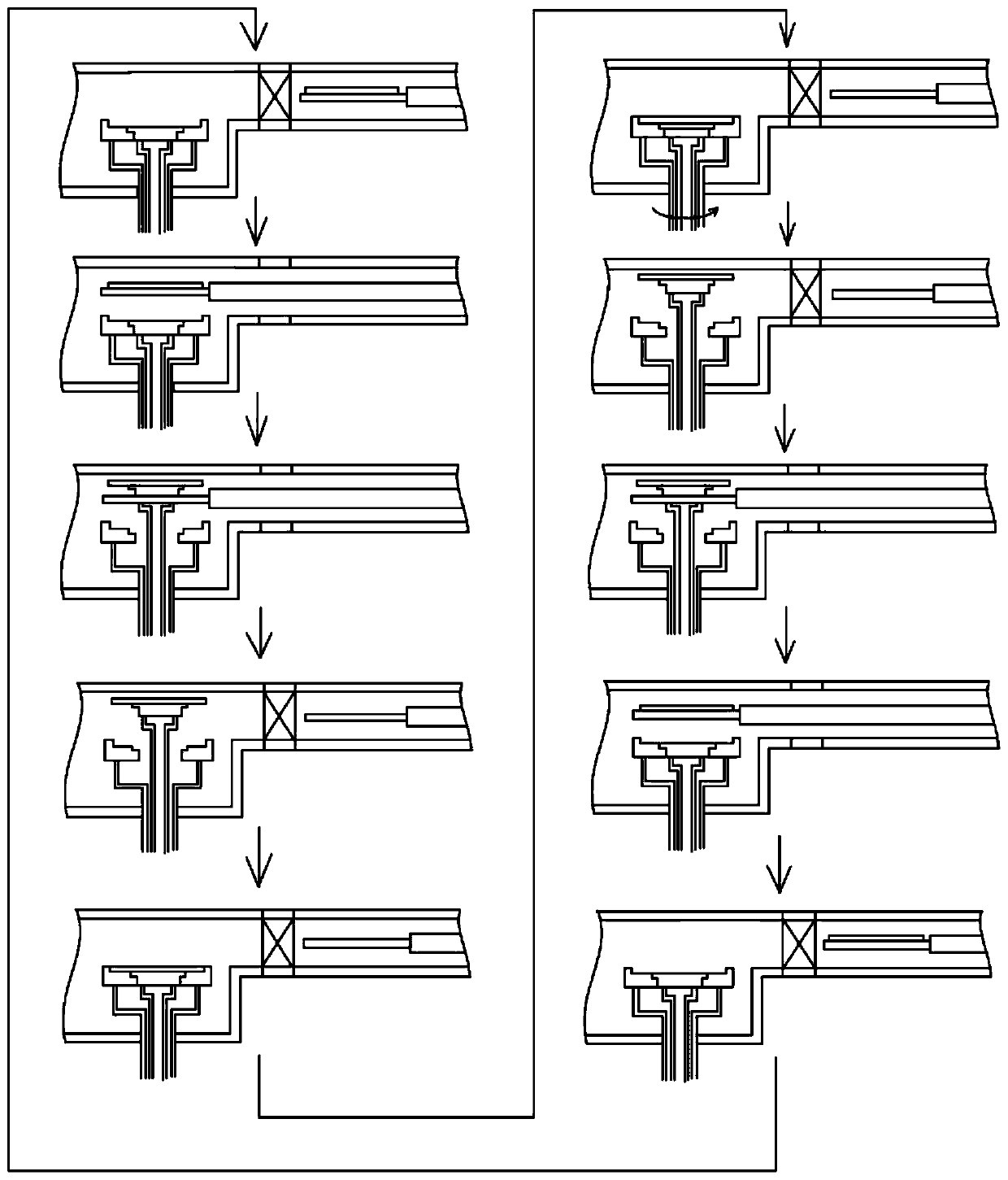

[0033] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

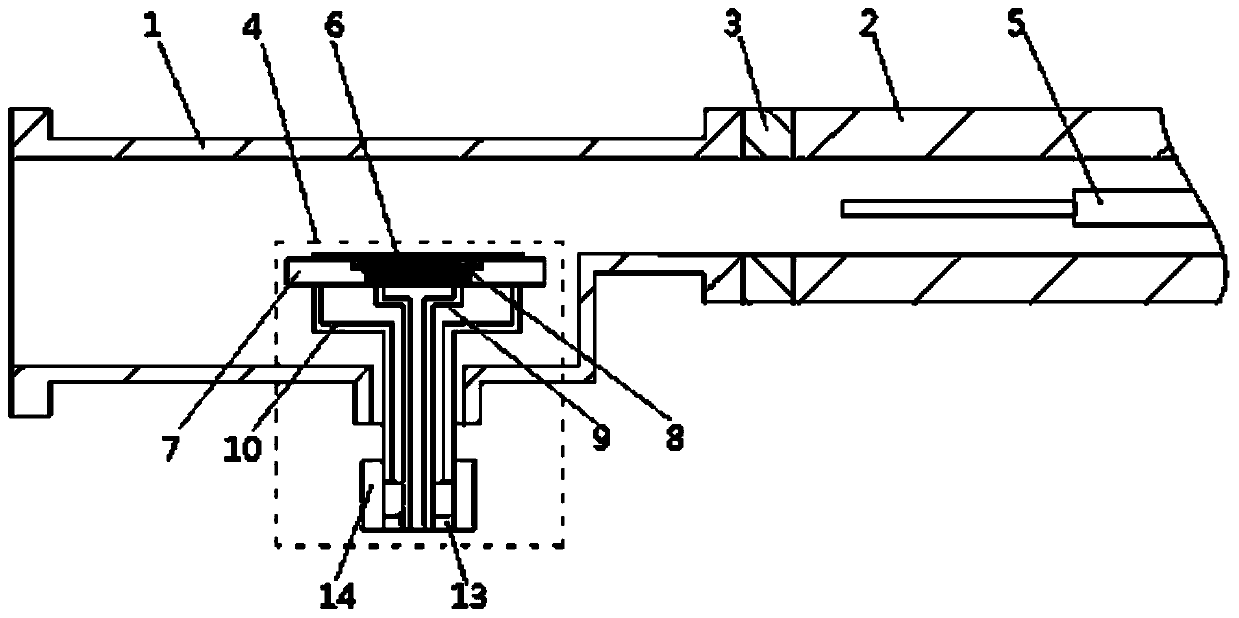

[0034] figure 1 Shown is a cross-sectional view of the front view of the entire structure of the wafer handling device for the reaction chamber. A wafer transmission device for a reaction chamber, comprising: a reaction chamber 1 , a transfer chamber 2 , a gate valve 3 , a wafer support part 4 , a mechanical transfer part 5 and a wafer 6 . Both the reaction chamber 1 and the transfer chamber 2 have a square cavity structure, and they are connected by a gate valve 3 .

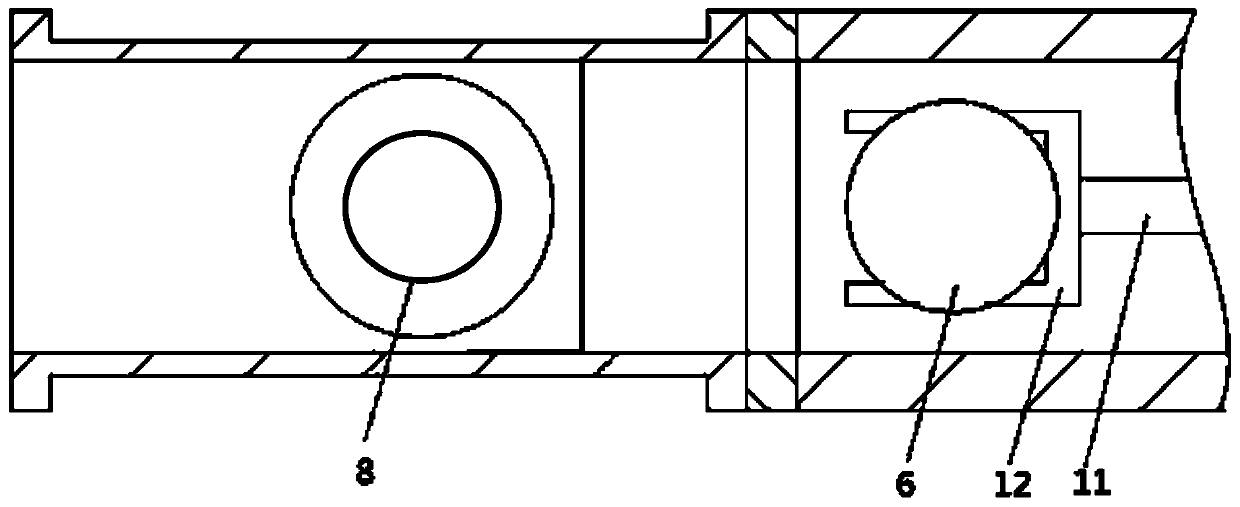

[0035] The wafer supporting part 4 includes: an outer ring base 7 , an inner ring base 8 , an inner ring support frame 9 and an outer ring support frame 10 . The inner ring base 8 includes a disc main body, a cylindrical boss is provided on the lower end of the disc, and the overall cross-section is T-shaped. The outer ring base 7 is circular, the inner ring of the outer ring base 7 is step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com