Method for extinguishing fire by utilizing fuel oil inert gas generator to directly convey inert gas to local ventilator

A local ventilation and generator technology, which is applied in mine/tunnel ventilation, earthwork drilling, fire prevention, etc. It can solve problems such as gas explosion, large closed area of fire area, and influence on normal production of mines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

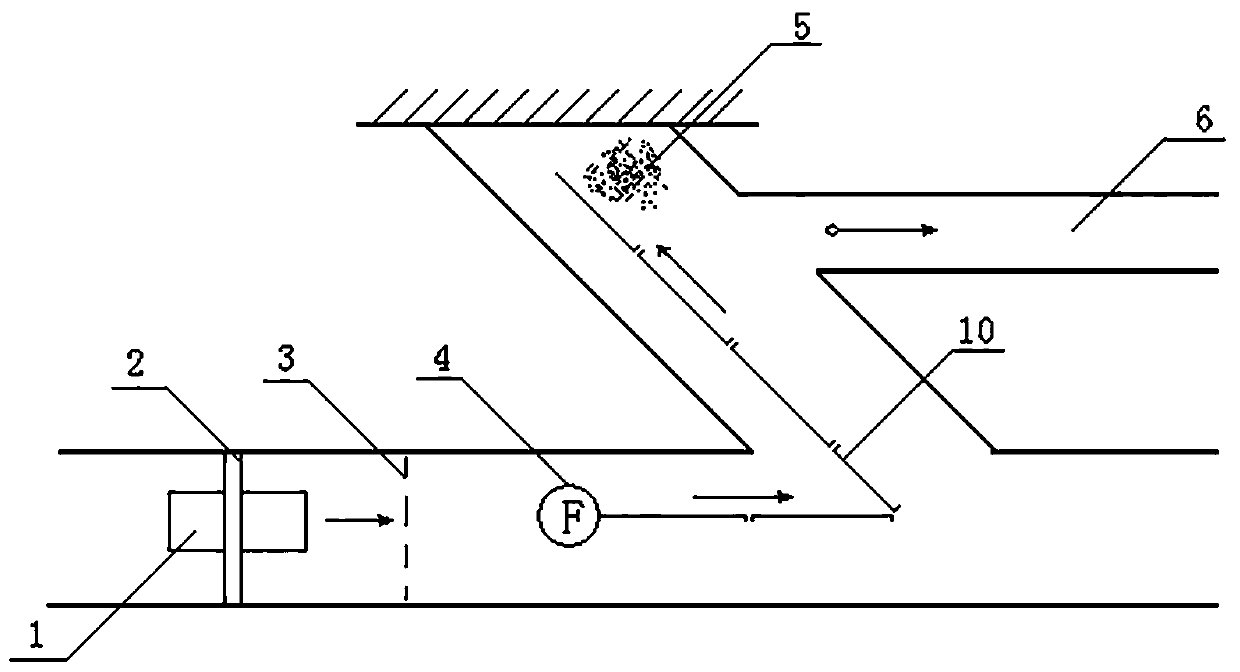

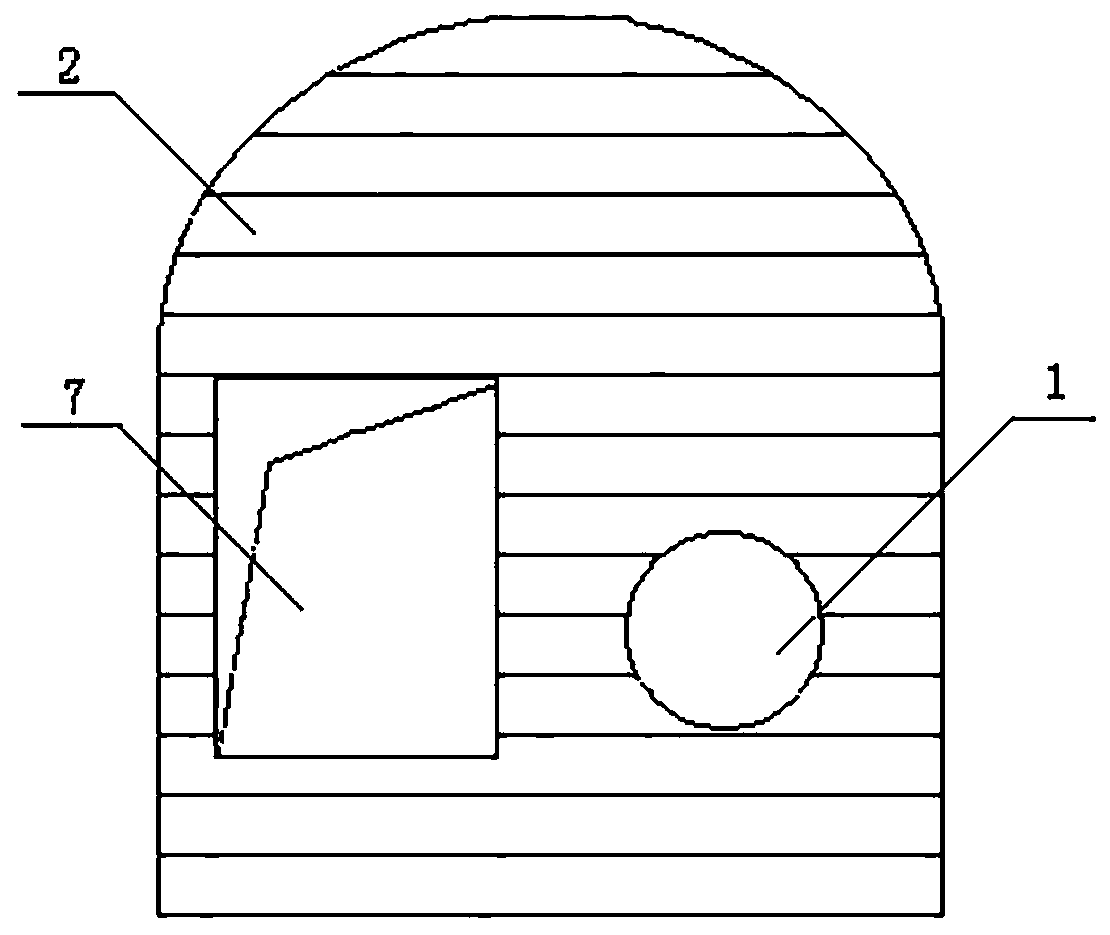

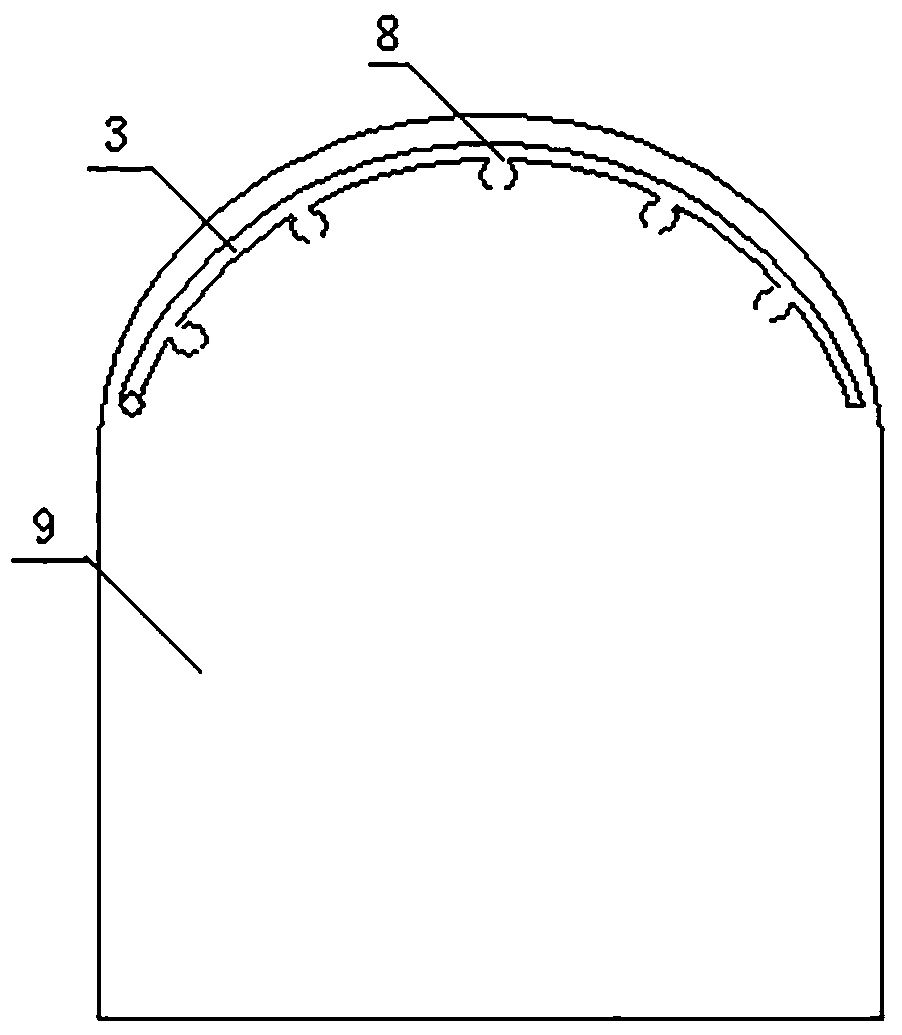

[0009] Install the inert gas generator 1 in the full negative pressure roadway on the windward side of the fan on the excavation face, build a temporary board wall 2 on top of the inert gas generator 1, leave the temporary board wall 2 to adjust the damper 7, and keep the damper 7 in the The open state ensures that the local ventilator 4 sucks enough air volume, keeps the ventilation stable, and closes the damper 7 after sending out the inert gas, so that the fan 4 inhales all the inert gas and transports it to the ignition point 5 through the blower 10. Before the inert gas is inhaled by the local ventilator 4, an annular water curtain 3 is set in the roadway, and the water curtain 3 is opened to cool down the inert gas during the process of inert gas generation, so as to ensure that the temperature of the inert gas will not melt the air duct, fan cable, fan blades and excavation. Equipment and facilities such as working face cables affect normal operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com