Bottle body transfer device

A conveying device and bottle technology, applied in packaging, conveyors, conveyor objects, etc., can solve problems such as bottle skew, and achieve the effect of avoiding skew and ensuring bottle quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

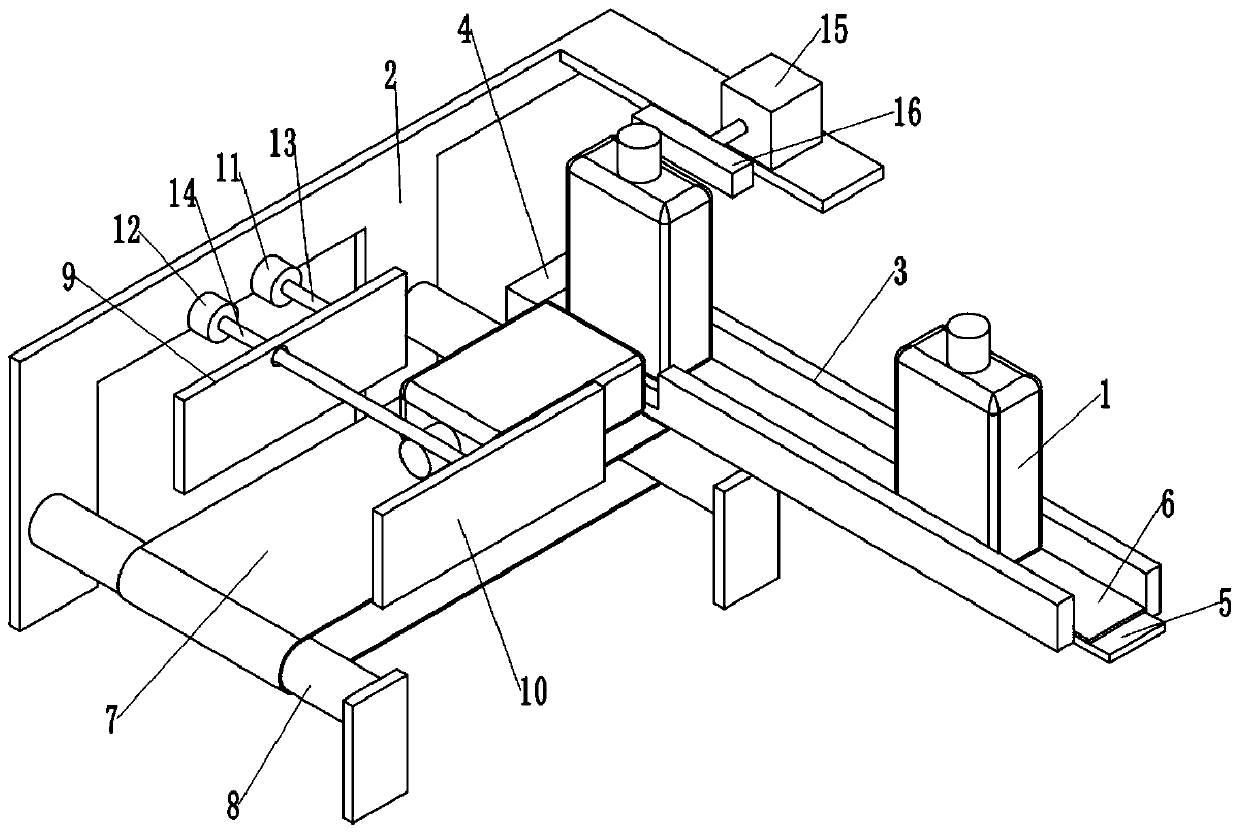

[0031] as attached figure 1 Shown: a bottle conveying device, including a frame 2, a first conveying unit and a second conveying unit, the first conveying unit is a conveying rail, the conveying rail includes an outer frame and a first conveyor belt 6, and the outer frame includes a stopper at the left end Plate 4 and the limit plate 3 on both sides, the baffle plate 4 and the limit plate 3 are fixed by bolts, the limit plate 3 is provided with a gap for transferring the bottle body; A first conveying roller (not shown in the figure), the first conveying roller is positioned between two spacer plates 3, and the first conveying belt 6 is tightened on the first conveying roller; One side of the first conveying roller is provided with for The first motor (not shown) that drives the first transmission roller to rotate, the first motor is fixed to the frame 2 by bolts, the output shaft of the first motor is fixed to the first transmission roller; A first support plate 5 for provid...

Embodiment 2

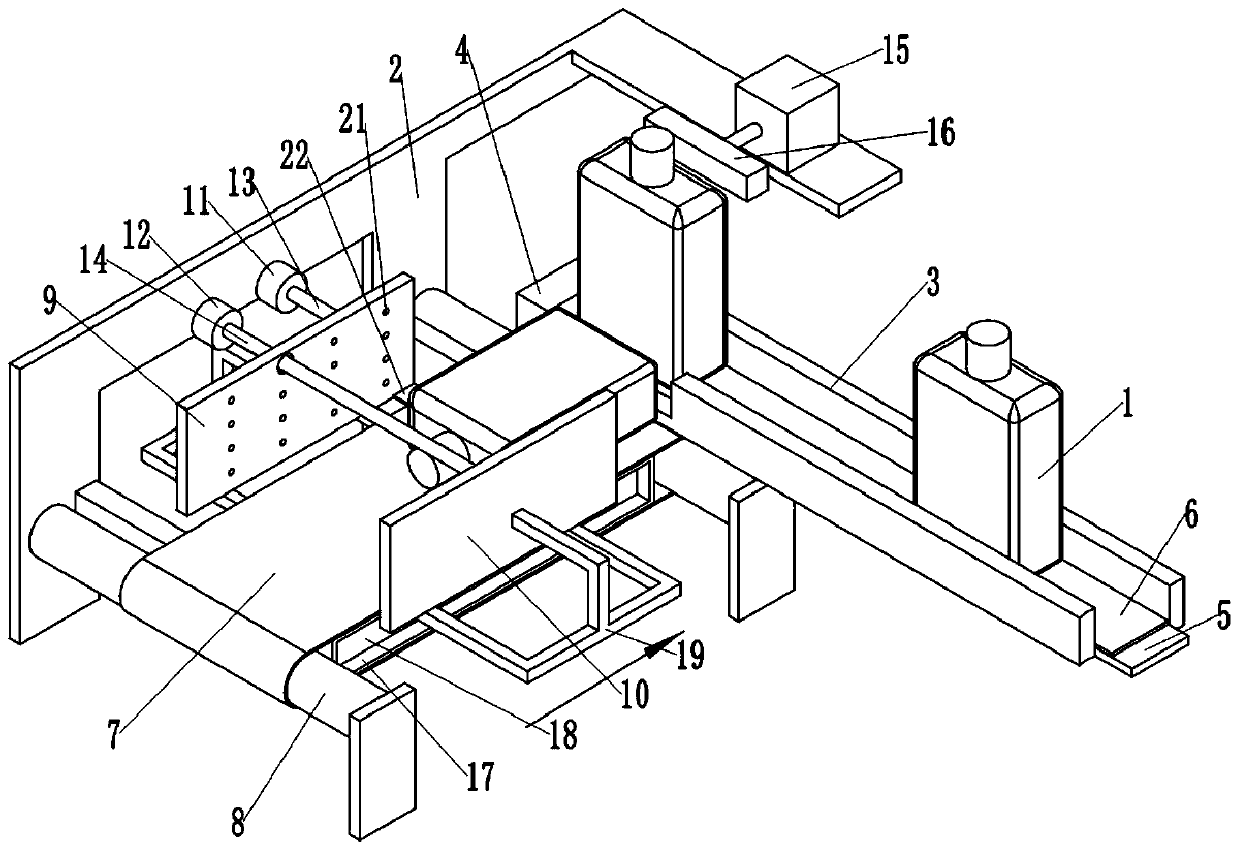

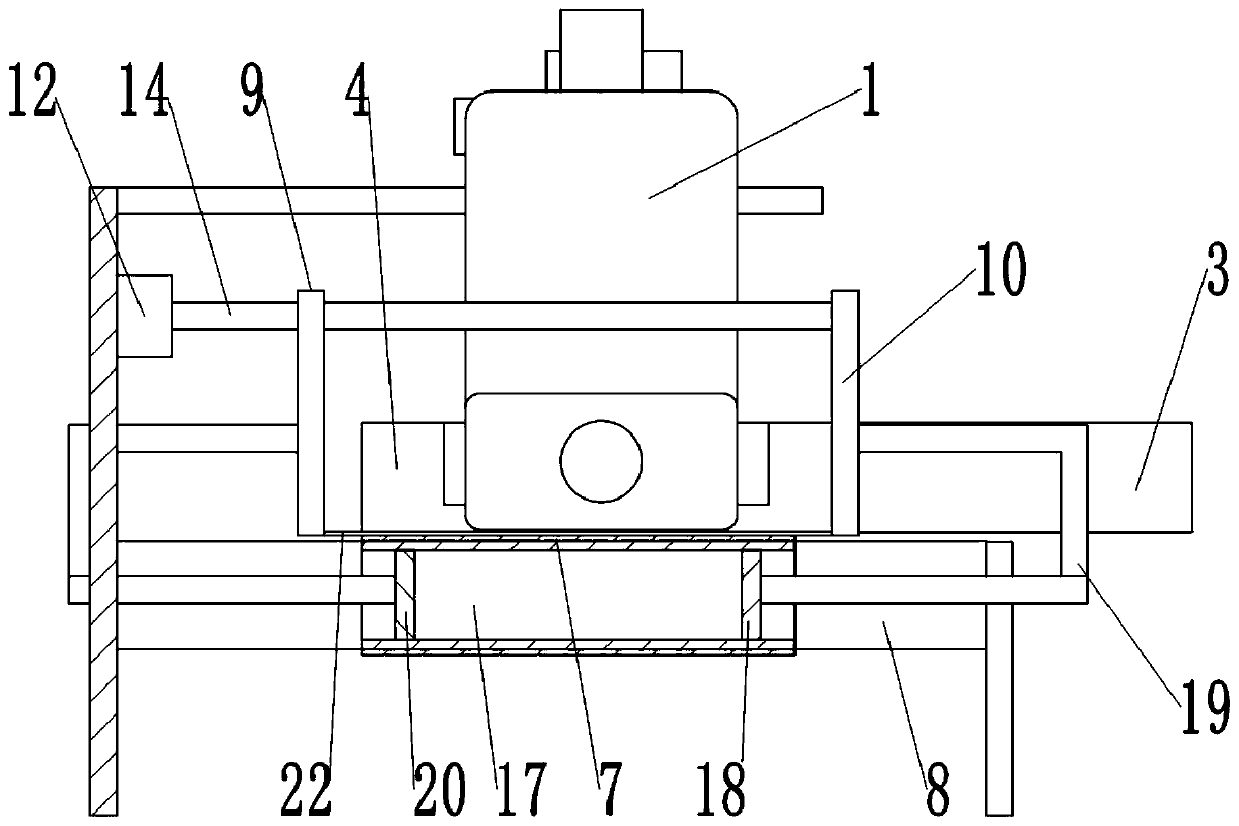

[0036] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the frame 2 is fixedly connected with a sealed box 17 by bolts, and the sealed box 17 is located in the closed area formed by the second conveyor belt 7, and as image 3As shown, the upper surface of the sealing box 17 is flush with the lower surface of the second conveyor belt 7 . A first piston 20 and a second piston 18 are slidably connected in the sealing box 17, and the first piston 20 and the second piston 18 are arranged oppositely. The sealing box 17, the first piston 20 and the second piston 18 jointly form a sealed space. The arrangement of the first piston 20 and the second piston 18 is the same, here the first piston 20 is taken as an example for illustration, as image 3 As shown, the left end of the first piston 20 is welded and fixed with a connecting rod 19, and the upper end of the connecting rod 19 is fixed with the first slide block 9 by bolts; the first slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com