A Locking Mechanism for CubeSat Separation and Evacuation

A technology of locking mechanism and separating mechanism, which is applied in the field of satellite launch, can solve the problems of infinite position, complex limit mechanism, low redundancy, etc., and achieve the effect of high limit reliability, convenient limit angle and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

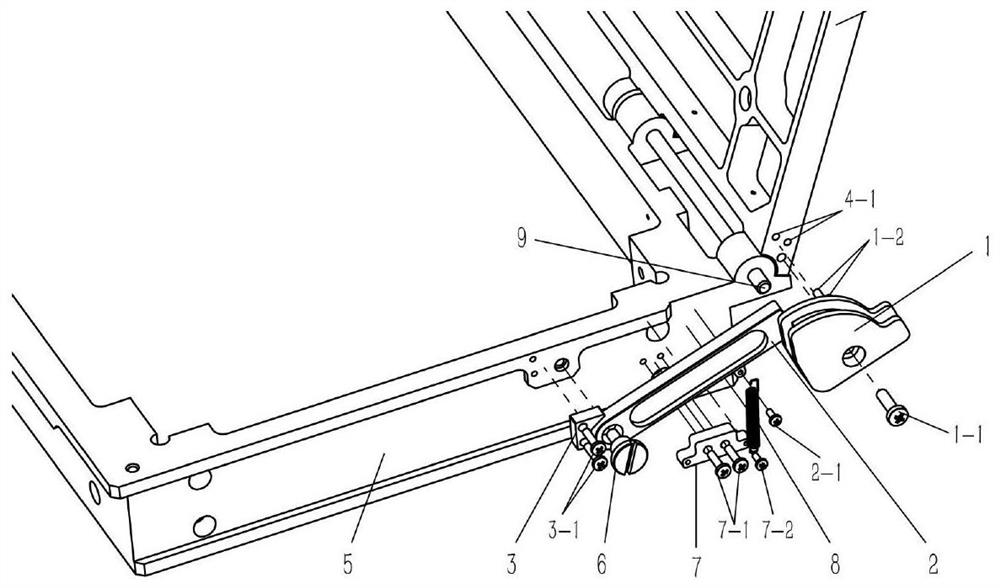

[0038] Embodiment 1, the locking mechanism for the separation of the CubeSat is in the launching stage.

[0039] Such as figure 2 , is a schematic diagram of the launch stage, the cube star is locked inside the separation mechanism, and the flip-limiting long plate (2) is in a static state under the joint action of the semicircular locking block (1), the tension spring (8) and the long plate shaft (6) .

Embodiment 2

[0040] Embodiment 2, the locking process of the cubic star separation and departure locking mechanism.

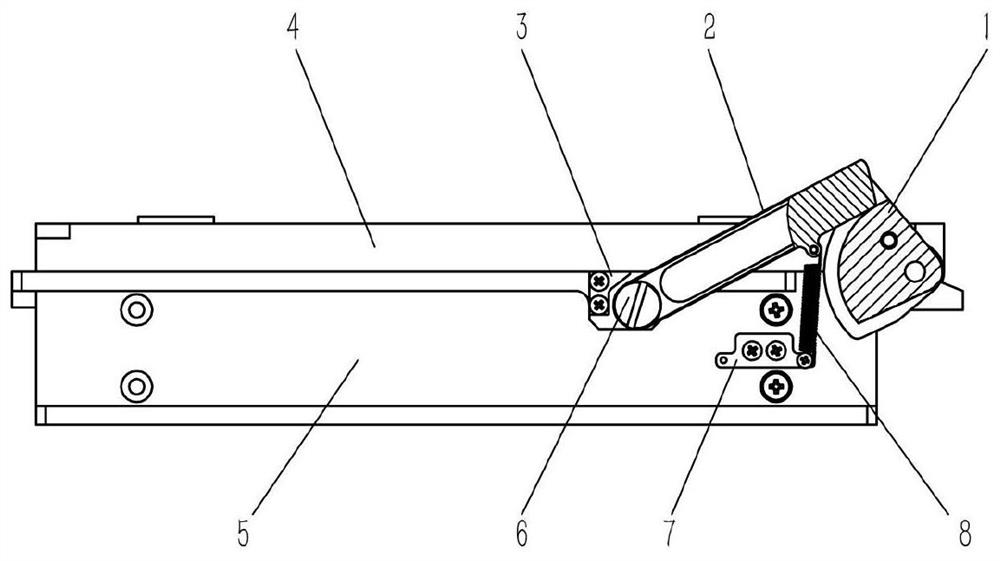

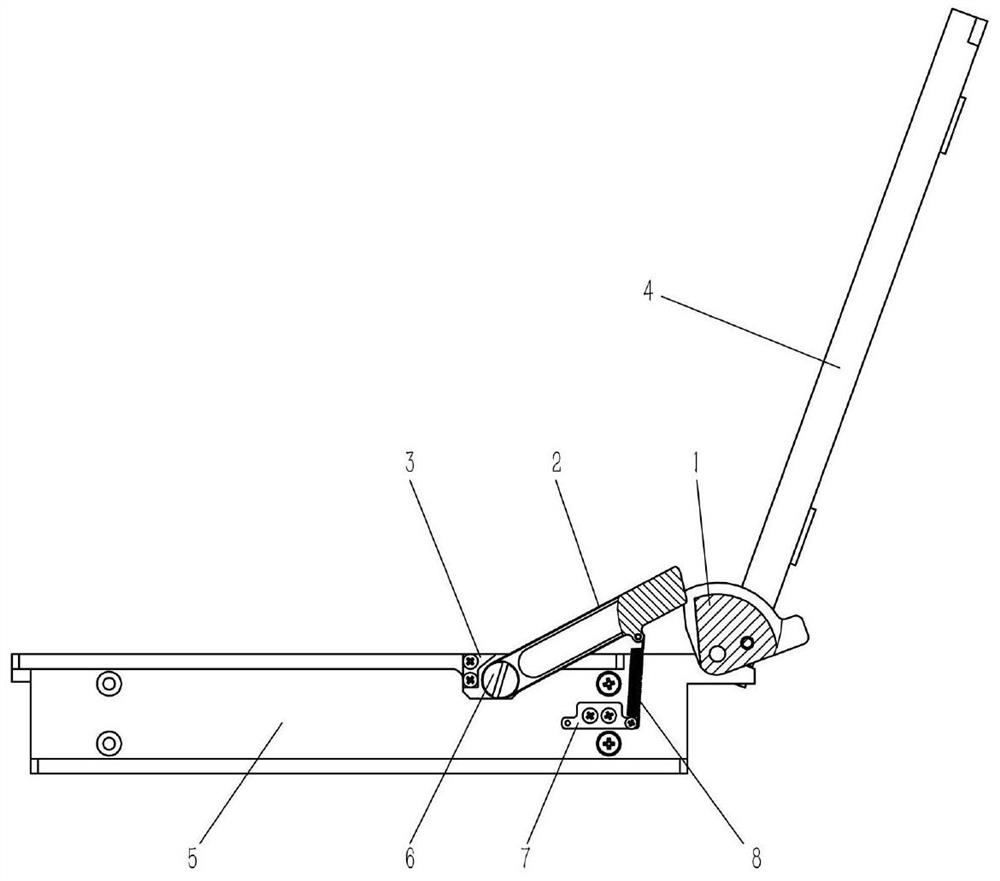

[0041] Such as Figure 3-5 , when the separation mechanism receives the separation signal, the flip cover (4) opens, and when the set angle is reached, the extension spring (8) shrinks, driving the flip limit long plate (2) to rotate around the long plate shaft (6), thereby moving along the Slide down the vertical inner surface of the semicircle locking block (1) to realize clamping of the semicircle locking block (1).

[0042] Such as image 3 As mentioned above, when the flip cover does not reach the maximum limit angle, the flip limit long plate (2) enters the redundant area in advance, so that the flip cover rotating plate moves downward to realize the limit, and the design of the redundant area reduces the required processing precision.

[0043] Such as Figure 4 As mentioned above, the tension spring (8) pulls the flip limit long plate (2) into the limit locking a...

Embodiment 3

[0051] Embodiment 3, the recovering stage of the locking mechanism for separation and departure of the cubesat after the ground test.

[0052] After the ground operator completes the test of opening the hatch, lift the flip limit long plates (2) on both sides of the separation mechanism with the middle fingers of both hands, and then press the hatch (4) together with the index fingers of both hands to complete the closing action.

[0053] Further, after the flip limit long plate (2) is lifted, it will be in contact with the limit stopper (3) such as Figure 7 Contact with the surface (3-2) in the center, thereby limiting its excessive displacement, protecting the extension spring (8) from being damaged by misoperation.

[0054] Further, as Figure 8 , the limit stopper (3) is positioned by the two through holes of (3-1) with screws and the separation mechanism top frame (5).

[0055] The working principle of the present invention is:

[0056] The semicircular locking block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com