Welding fixture for network transformer

A technology of network transformers and welding fixtures, which is applied in the field of fixtures and fixtures, can solve problems such as single clamping method of fixtures, inability to combine fixation, welding errors, etc., and achieve the effect of improving welding quality, improving fixing quality, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

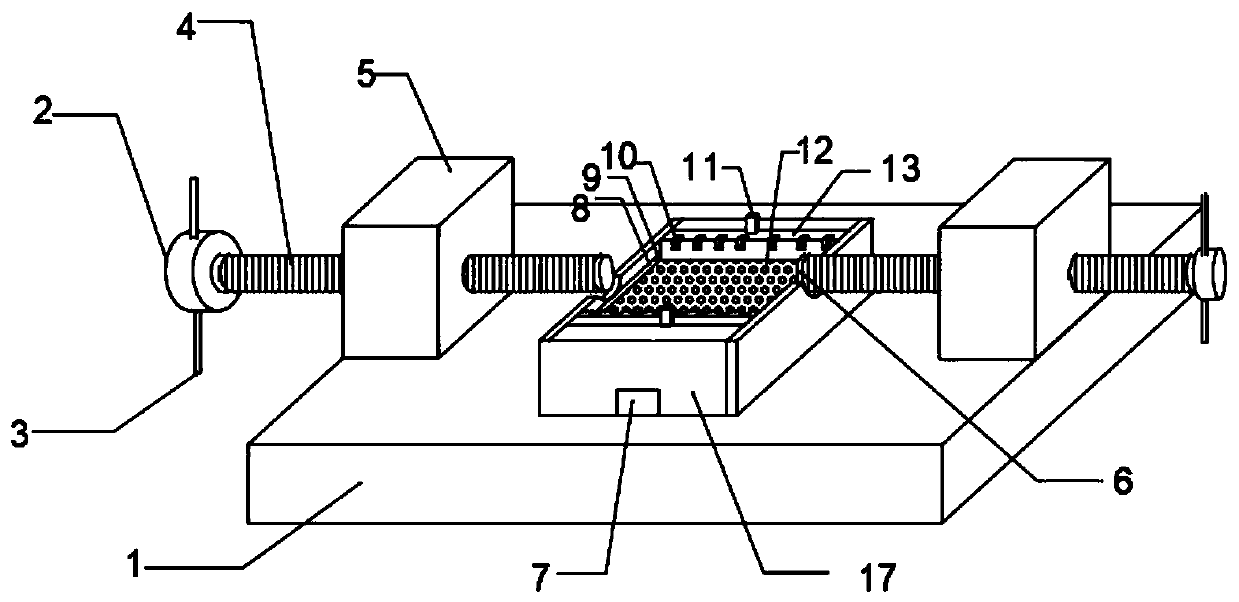

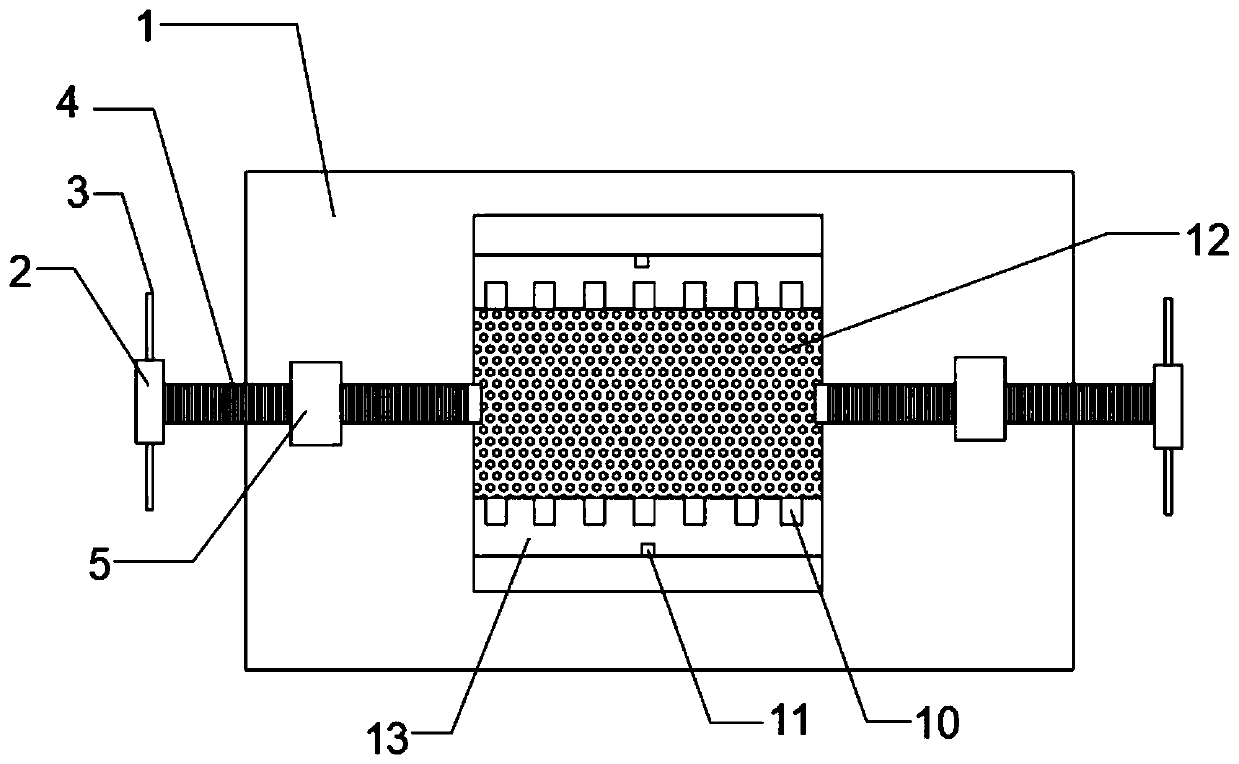

[0020] refer to Figure 1-2 , a network transformer welding fixture tooling, including a base 1, the outer walls of both ends of the top of the base 1 are fixedly connected with nuts 5, the inside of the nut 5 is provided with a screw 4, the screw 4 and the nut 5 are rotatably connected, and the screw 4 is away from the nut 5. One end is fixedly connected with a rotating block 2, the outer wall of the rotating block 2 is fixedly connected with a plurality of rotating rods 3, a workbench 17 is arranged between the two sides of the nut 5, the outer wall of the bottom of the workbench 17 is fixedly connected with the outer wall of the top of the base 1, and the workbench Both sides of the top of 17 are provided with a mobile platform 13, the top of the mobile platform 13 is provided with a plurality of card slots 10, the bottom of the mobile platform 13 is provided with a groove, and the inside of the groove is provided with a magnetic strip 7. 10 and the magnetic strip 7 triple ...

Embodiment 2

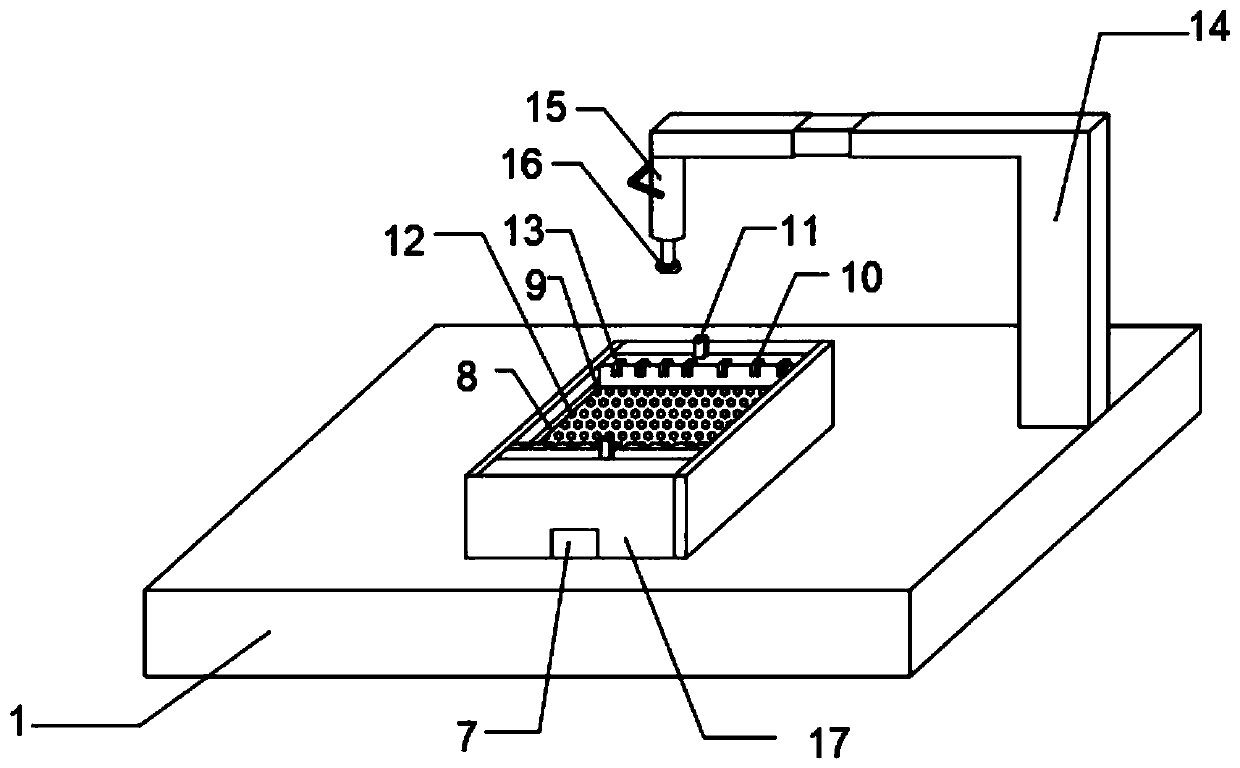

[0027] refer to image 3 , a network transformer welding fixture tooling, the outer wall of the top end of the base 1 is fixedly connected with a fixed frame 14, the fixed frame 14 is far away from the outer wall of the base 1, and the bottom outer wall is provided with a hand-pressed hydraulic rod 15, and the bottom of the hand-pressed hydraulic rod 15 is fixedly connected with a The second rubber pad 16.

[0028] When in use, just put the object between the mobile platforms 13, and then snap it into the card slot 10. After fixing the object, use the hand-pressed hydraulic rod 15 to press the object, and then put the magnetic strip 7 at the bottom of the workbench 17, and the whole is completely fixed. Afterwards just can carry out welding, by being provided with the fixing mechanism of hand pressure type hydraulic rod 15 fixing mechanism, draw-in groove 10 and magnetic strip 7 triple compound, can effectively improve fixing quality, thereby improve welding quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com