Double guide-bar telescoping mechanism for motor vehicle equipment

A telescopic mechanism, double guide rod technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of increased production cost, troublesome operation, damage of parts, etc., to avoid damage to parts, reduce floor space, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

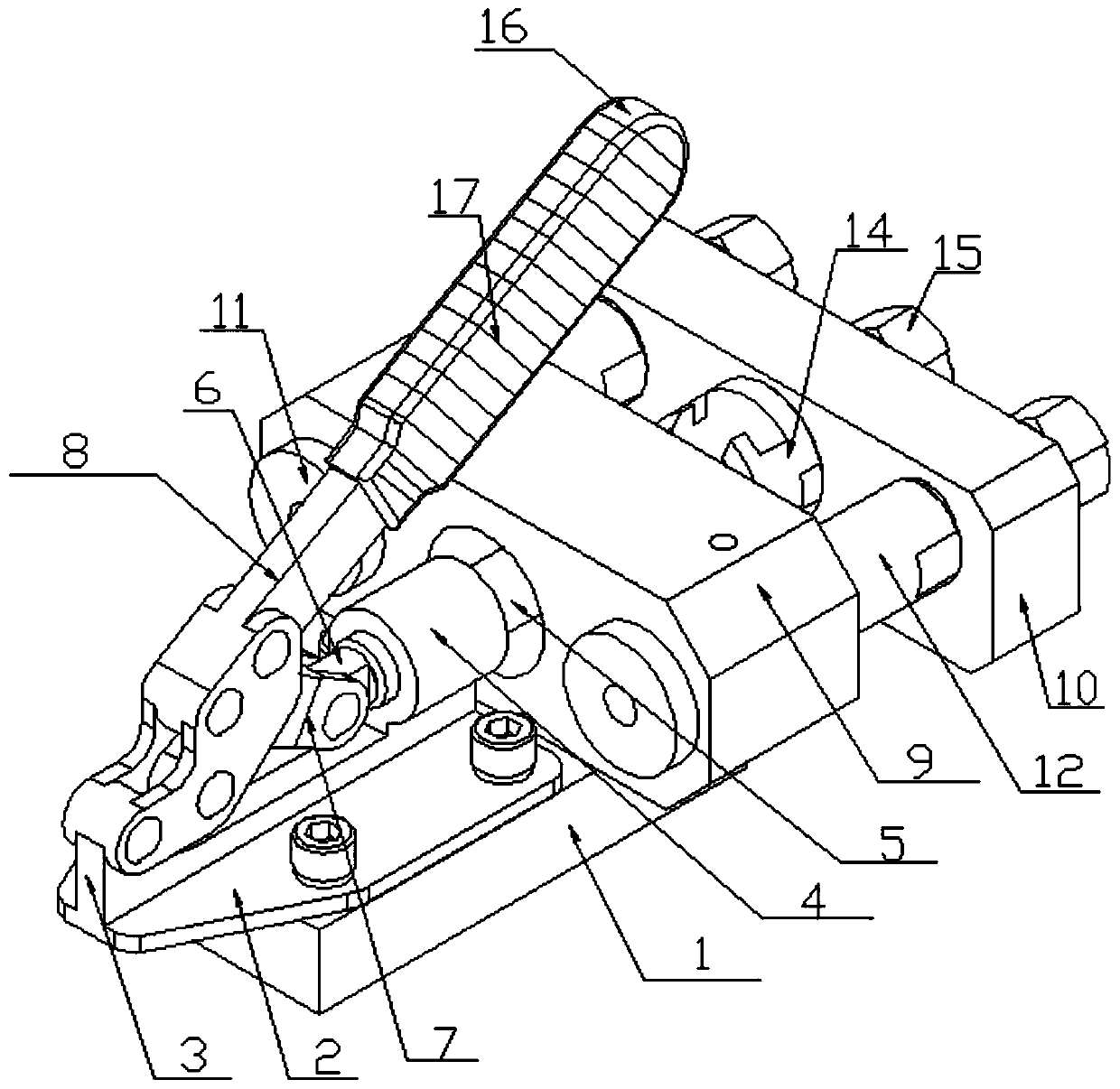

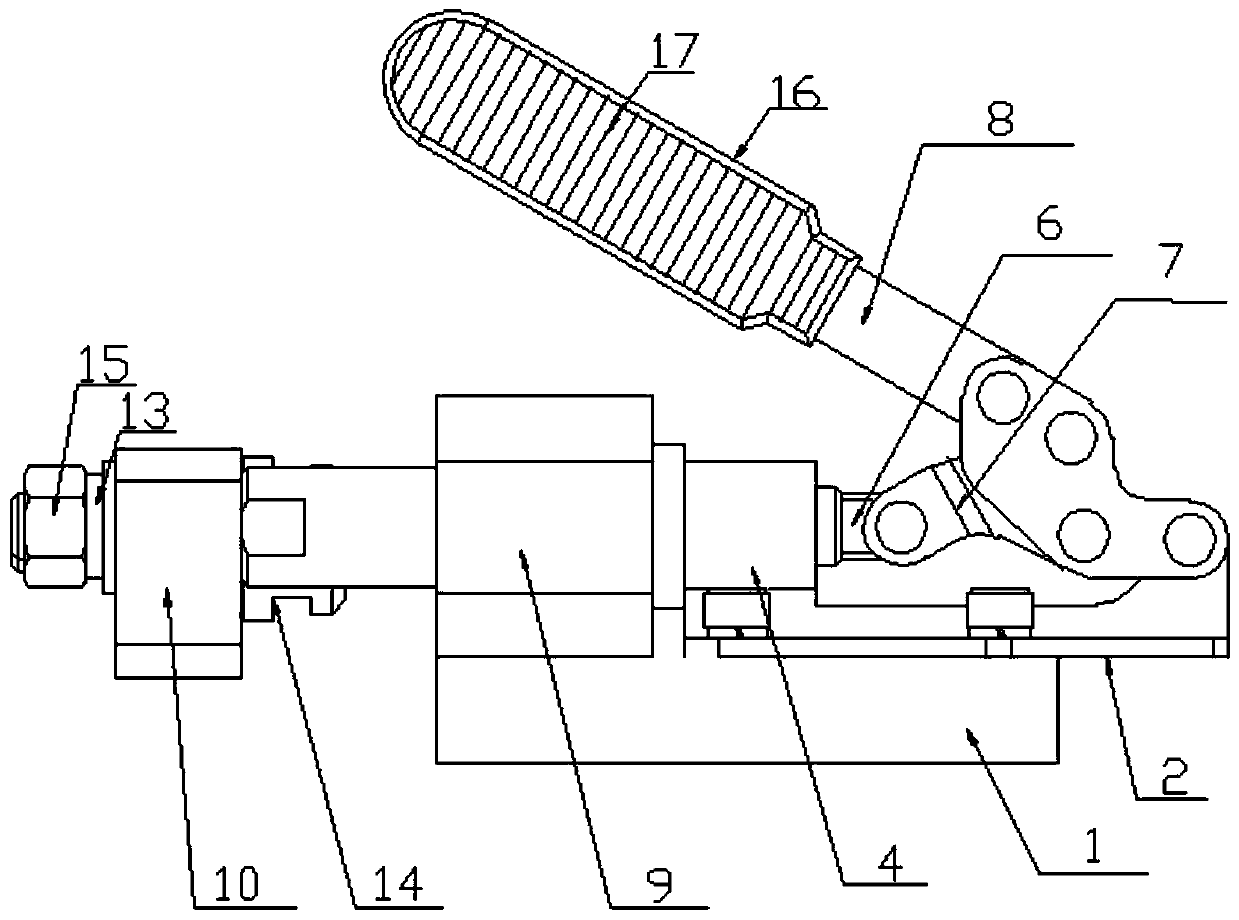

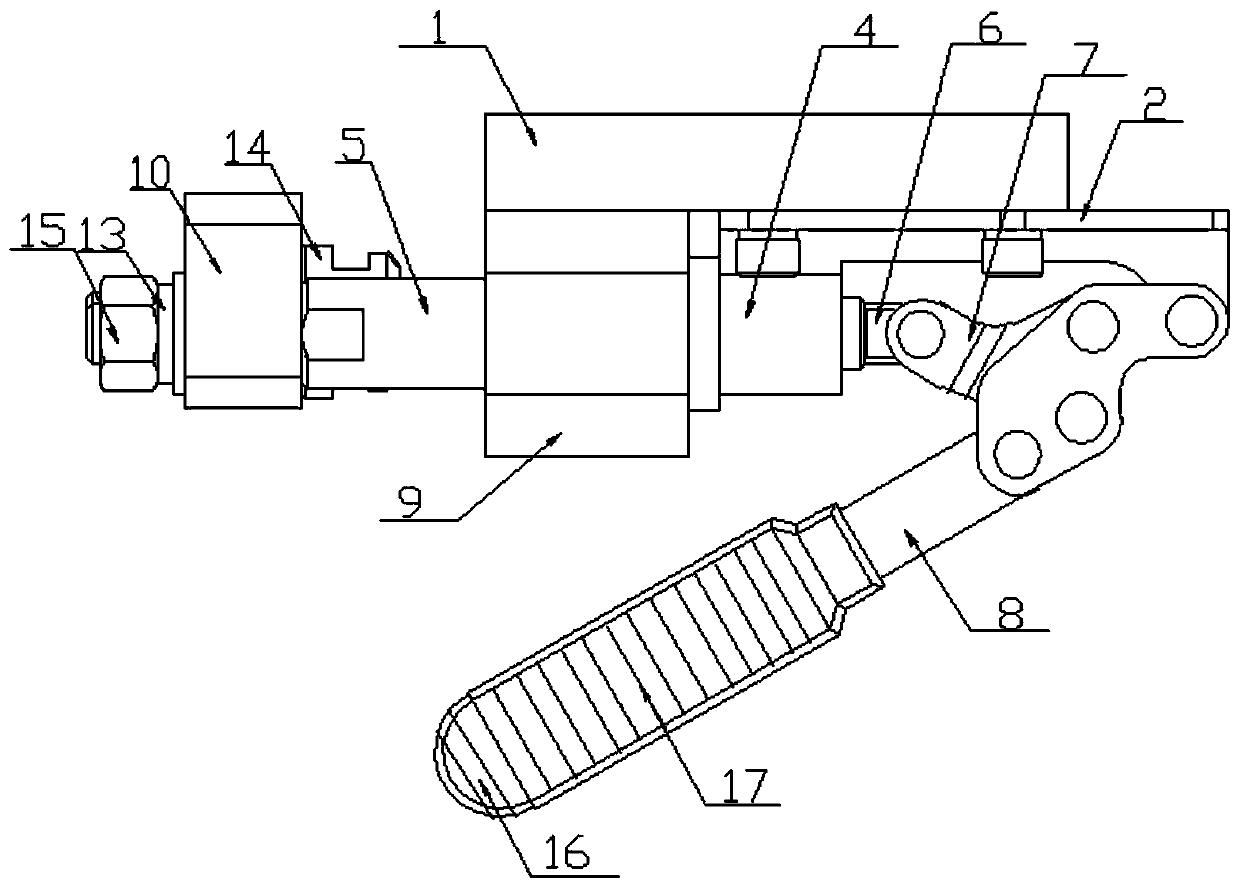

[0014] The invention provides a double guide rod telescopic mechanism for automobile equipment, which is characterized in that it includes a bottom plate 1, a mounting plate 2, a mounting block 3, a connecting column 4, a push rod 5, a connecting block 6, a pulling member 7, and a clamp 8 , piercing plate 9, vertical plate 10, perforation, mounting hole, stopper 11 in place, guide rod 12, mounting rod 13, movable joint 14, nut 15, the upper side of bottom plate 1 is installed with mounting plate 2 through bolts, and mounting plate 2 is "Inverted T-shaped" structure, one end of the mounting plate 2 is installed with a mounting block 3, the mounting block 3 and the mounting plate 2 are integrated, the mounting block 3 is equipped with a clamp 8, and the outer side of the clamp 8 is covered with a plastic shell 16, The plastic shell 16 is provided with anti-slip lines 17, the other end of the mounting plate 2 is welded with a connecting column 4, the connecting column 4 is connect...

Embodiment 2

[0016] The installation process of the present invention: first install the mounting plate 2 on the base plate 1, the through plate 9 is installed on the front side of the mounting plate 3, the through plate 9 is provided with two mounting holes and a perforation, and the pulling member 7 is installed on the On the mounting plate 2, the clamp 8 is installed on the mounting block 3 of the mounting plate 2, the clamp 8 is covered with a plastic shell 16, and the plastic shell 16 is provided with anti-slip lines 17, the clamp 8 is connected with the pulling block 7, and then Connect the connecting block 6 at one end of the push rod 5 with the puller 7, the inside of the push rod 5 is a hollow structure, the inside of the push rod 5 is provided with internal threads, the push rod 5 passes through the through hole of the through plate 9, and the vertical plate 10 Installed on the front side of the through-board 9, the vertical board 10 is provided with two installation holes and a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com