Straightening device based on screw compression adjustment and using method

A screw compression and straightening technology, applied in the field of straightening devices based on screw compression adjustment, can solve the problems of equipment volume, weight, inconvenient handling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0042] The method for using the straightening device based on screw compression adjustment is characterized in that it includes the following steps:

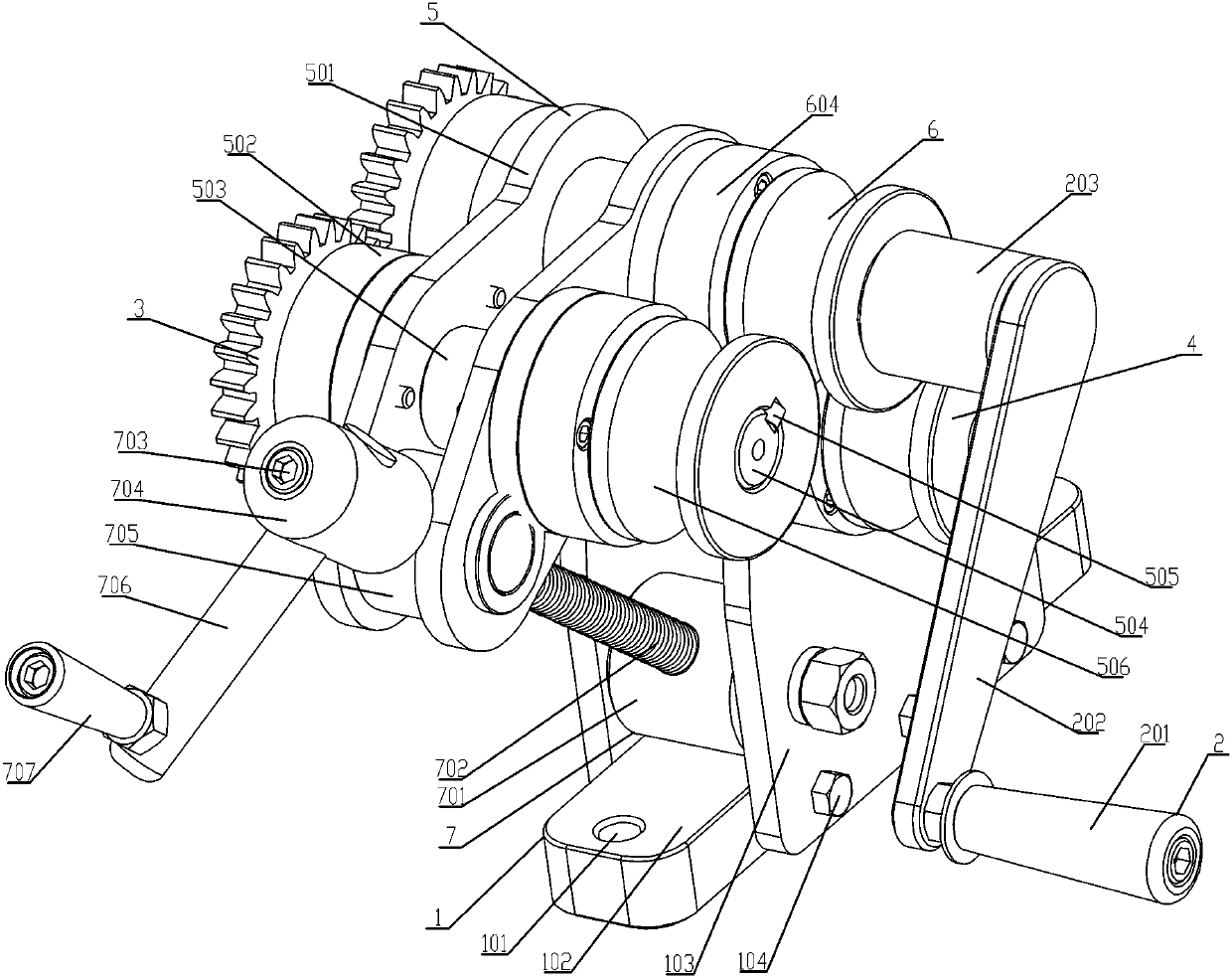

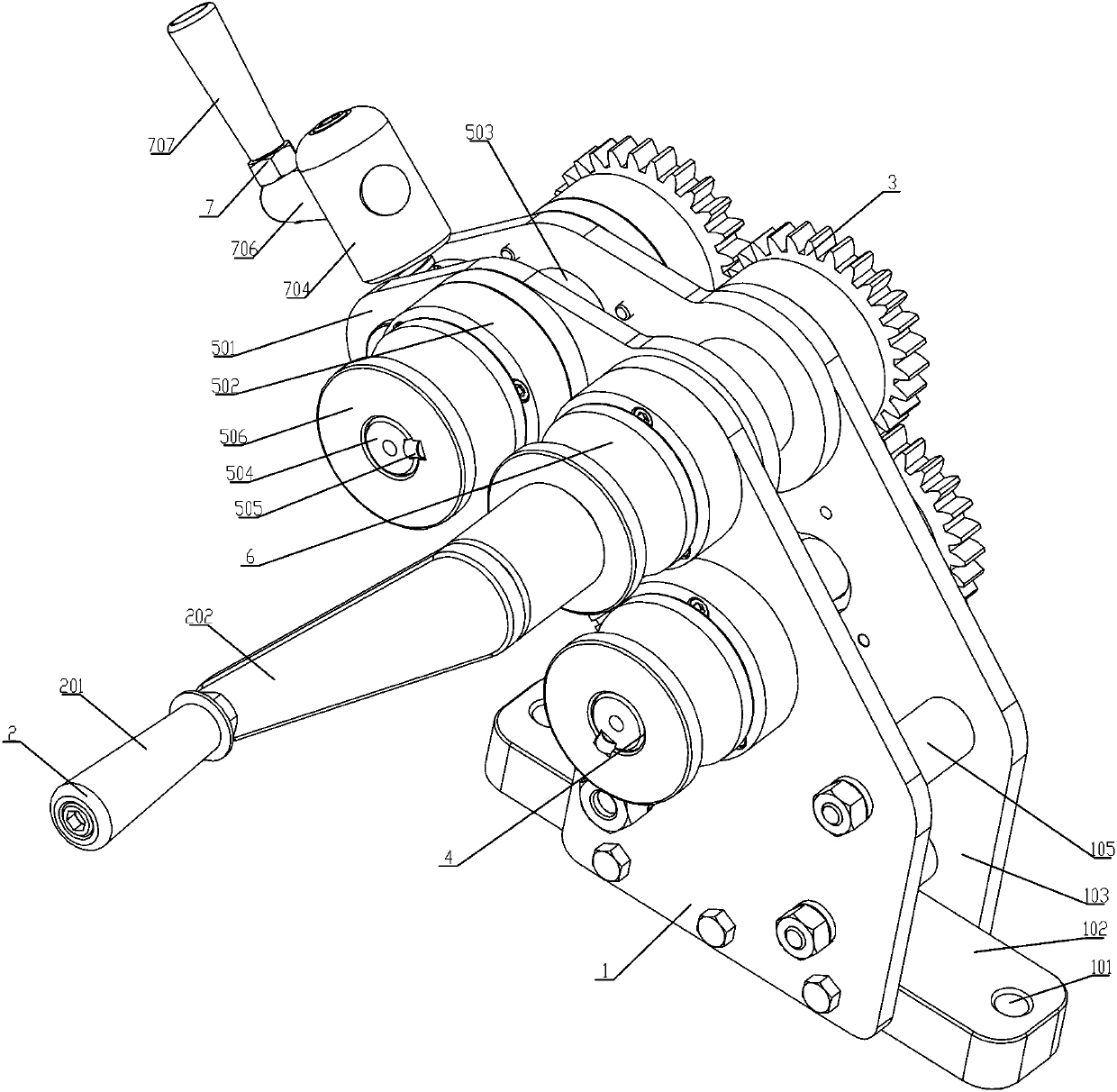

[0043] Step1: Adjust the position of the swinging roller mechanism 5 according to the diameter of the pipe or bar to be straightened, and ensure that the pipe or bar to be straightened can pass through the bottom roller structure 4, the swinging roller mechanism 5 and the top roller Triangular straightening mechanism composed of structure 6;

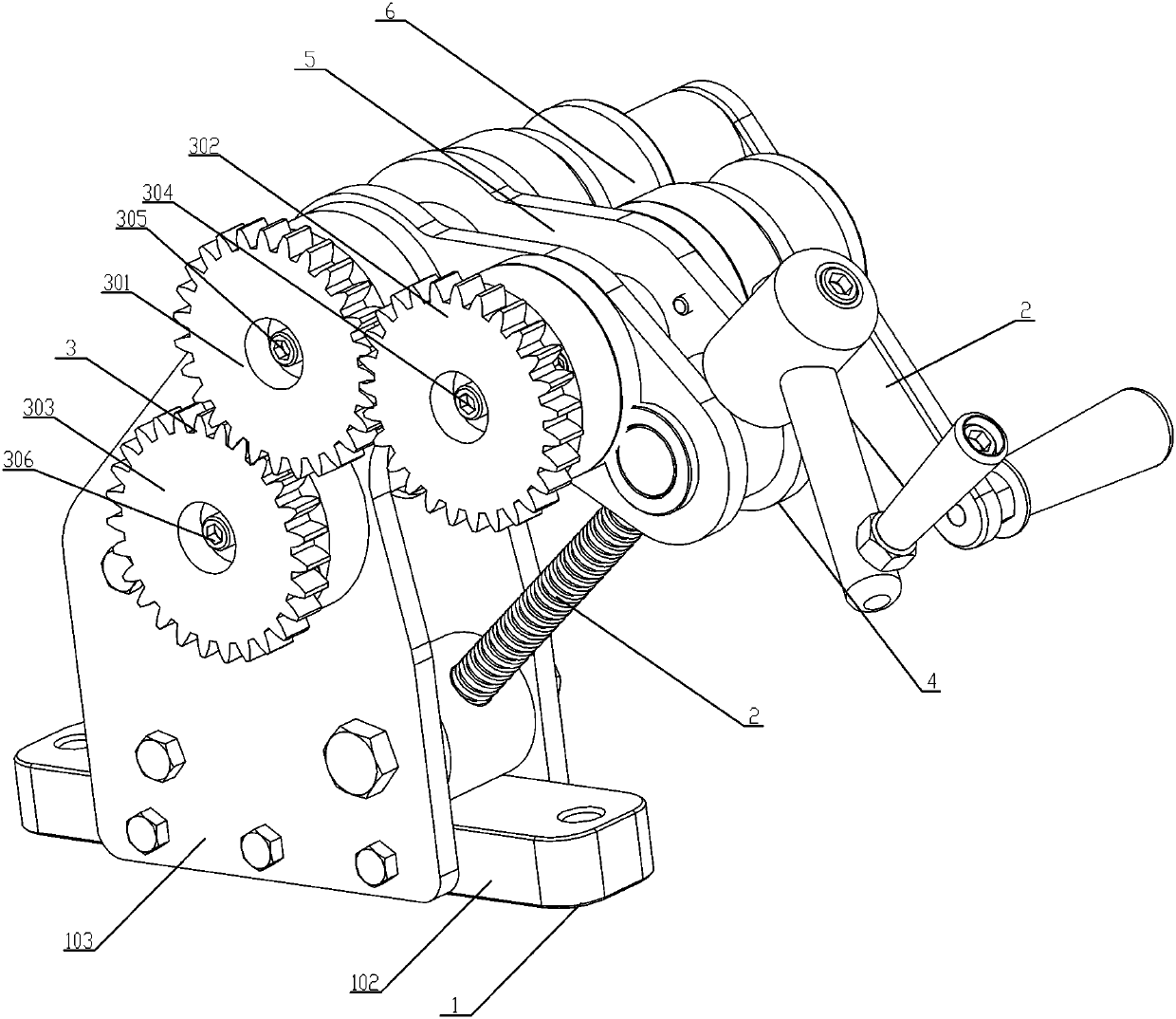

[0044] Step2: Drive the power mechanism 2, manually rotate the first handle 201, drive the first rotating arm 202 to rotate through the first handle 201, and then drive the second straightening roller 602 of the top pressure roller structure 6 to rotate through the first rotating arm 202;

[0045] Step3: The second main shaft 601 where the second straightening roller 602 is located will drive the gear transmission mechanism 3 including the first gear 301. The second gear 303 and the third gear 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com