An air gap painting device for furniture

An atmosphere and gap technology, applied in the direction of spraying device, spraying device, liquid spraying device, etc., can solve the problem of wasting paint water and achieve the effect of protecting health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

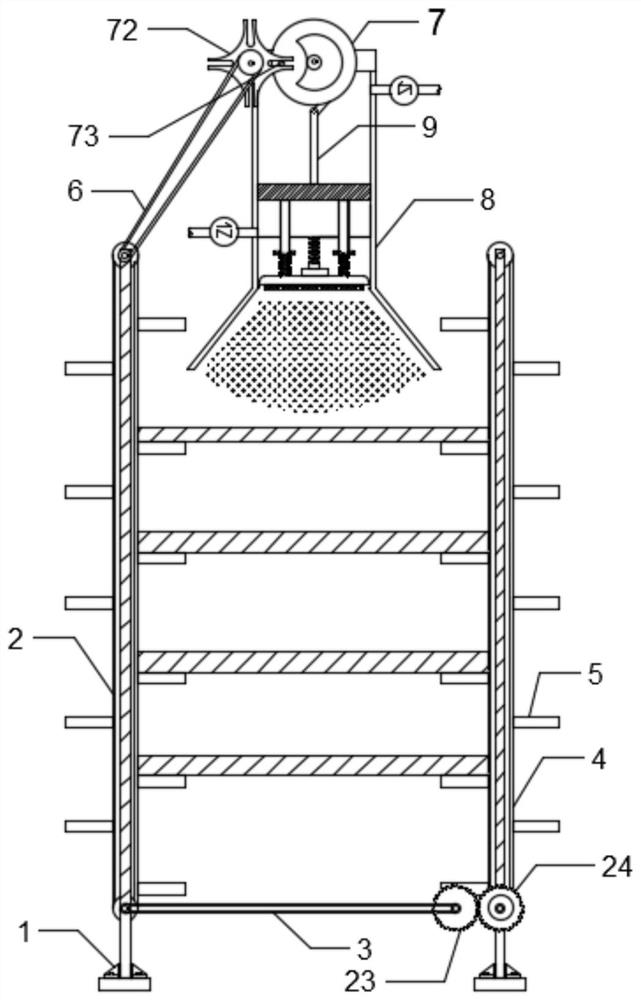

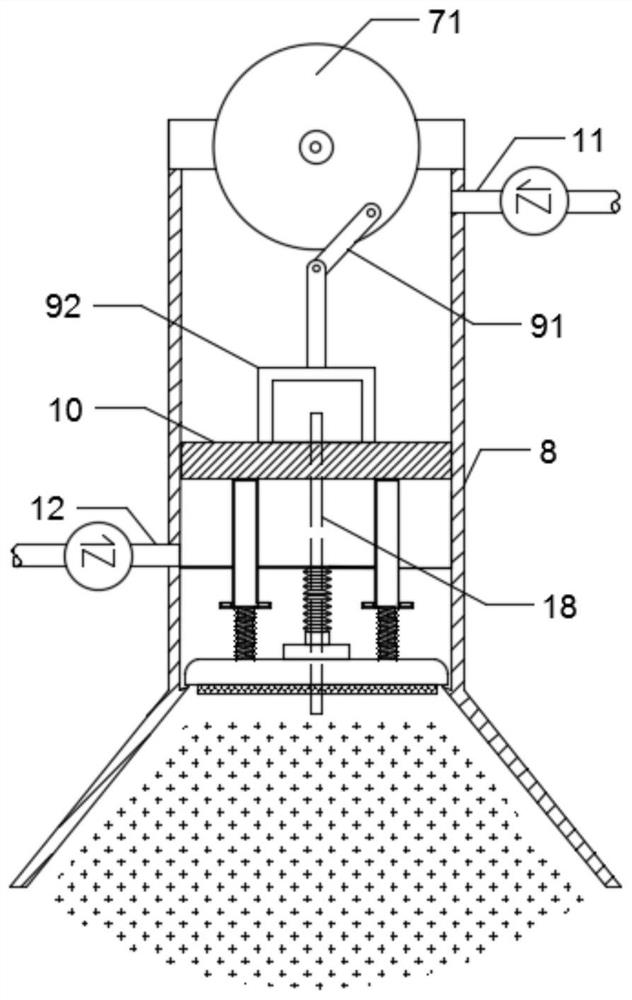

[0028] refer to Figure 1-4 , an atmosphere gap painting device for furniture, comprising a bracket 1, a discharge mechanism is provided on one side of the bracket 1, the discharge mechanism includes a support rod 20, a cylinder 21 and a push plate 22, and the support rod 20 is fixedly connected to the support 1 , the cylinder 21 is fixedly connected to the pole 20, and the push plate 22 is fixedly connected to the output shaft of the cylinder 21.

[0029] The middle part of the bracket 1 is provided with a moving mechanism, and the moving mechanism includes a first conveyor belt 2, a second conveyor belt 3, a third conveyor belt 4, a first gear 23, a second gear 24 and a pallet 5, and the first gear 23 and the second gear 24 are all Rotationally connected to the bracket 1, the first gear 23 meshes with the second gear 24, the first conveyor belt 2 and the third conveyor belt 4 are respectively rotatably connected to both sides of the bracket 1, and one end of the second conve...

Embodiment 2

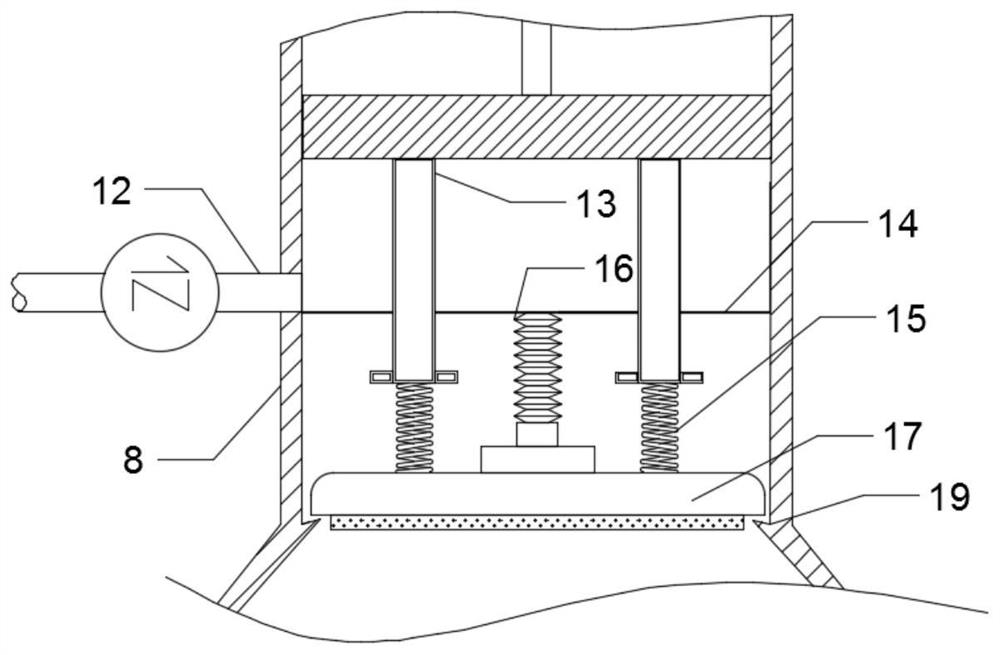

[0037] On the basis of Embodiment 1, it is further set as follows: an exhaust pipe 18 is fixedly connected to the middle of the circular plate 10, and the exhaust pipe 18 passes through the telescopic pipe 16 and the nozzle 17. When the circular plate 10 moves upward, the piston cylinder 8 The gas above the inner circular plate 10 is sprayed downward at the nozzle 17 through the exhaust pipe 18, so that the remaining paint water in the air above the wooden board can be sprayed onto the wooden board, and at the same time, the air flow above the wooden board is accelerated to dry the paint water. faster; and the vertical placement of the exhaust pipe 18 has a position-limiting effect, which can keep the spray head 17 moving in the vertical direction, avoiding the horizontal shaking of the spray head 17, thereby preventing the spray head 17 from spraying paint water to The waste of paint water caused by places other than planks; and the exhaust pipe 18 has passed through the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com