Electric motor

An electric motor and electric conductor technology, applied in electric components, electromechanical devices, electrical components, etc., can solve the problems of increased particle load, cooling to ambient temperature, etc., to achieve the effects of improved cleanliness, simplified disassembly, and low overhead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

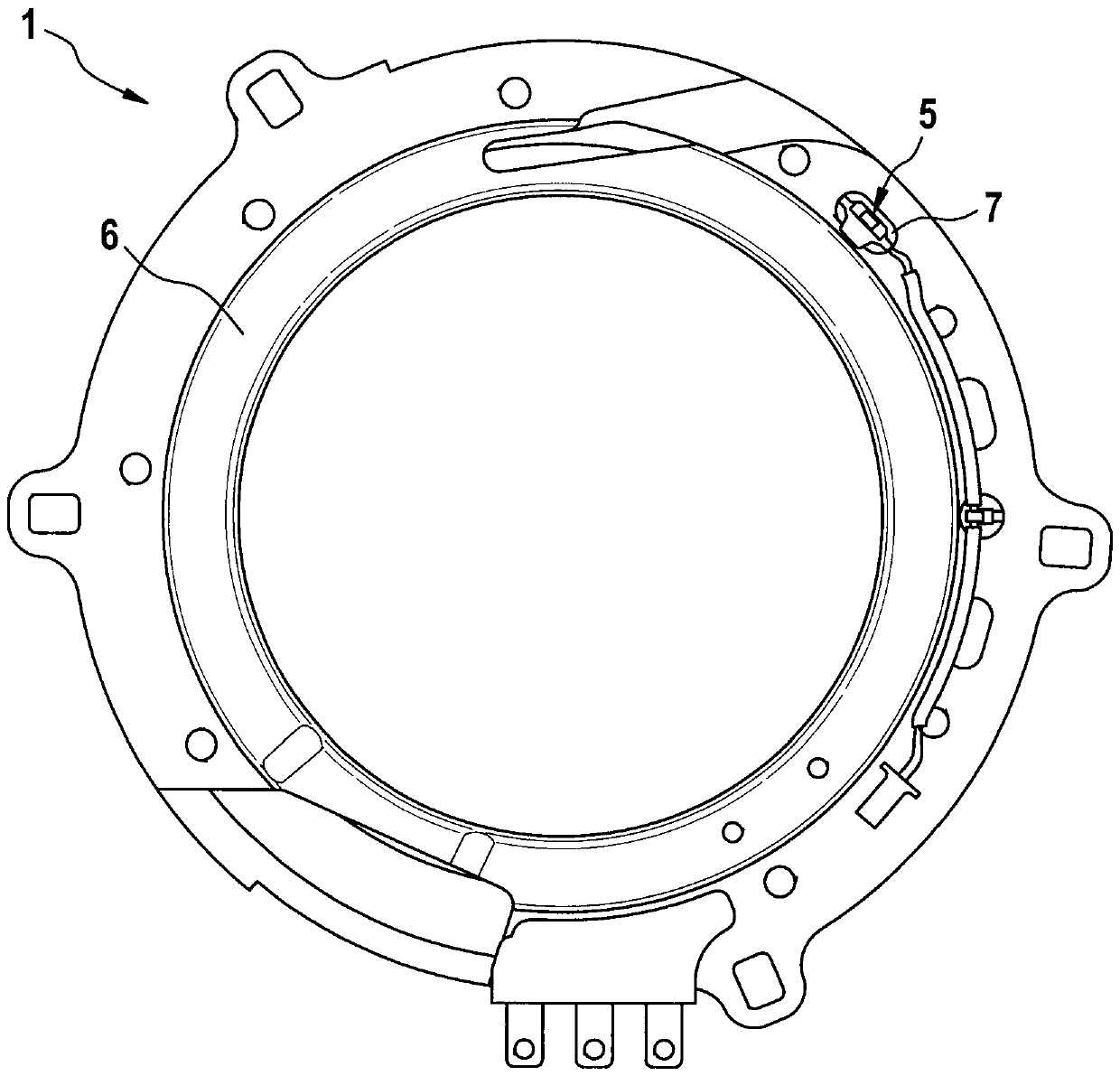

[0043] FIG. 1 schematically shows a detail of an electric motor 1 according to the prior art. The electric motor has already been described at the outset.

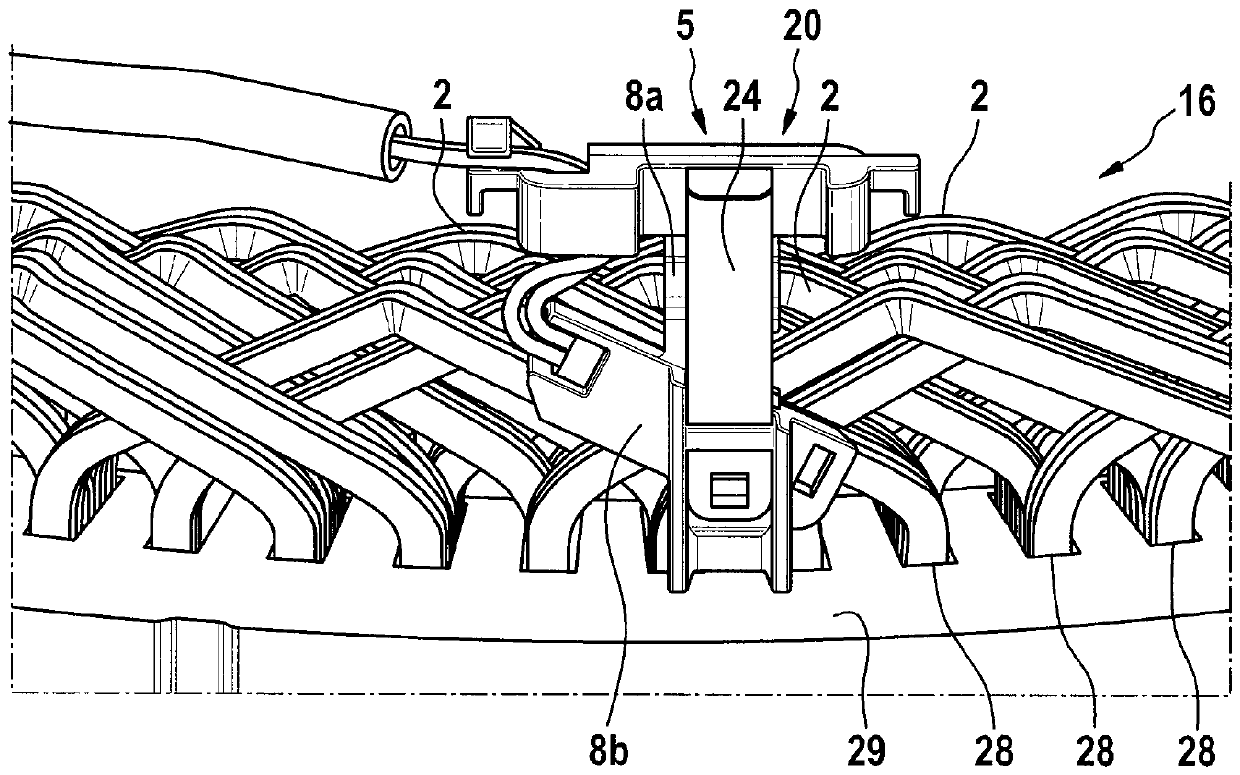

[0044] figure 2 A section of an electric motor 1 according to a first exemplary embodiment of the invention is shown schematically. The electric motor 1 includes a coil winding 16 with a plurality of conductors 2 for generating an electric field. Furthermore, the electric motor 1 includes a surrounding housing 6 .

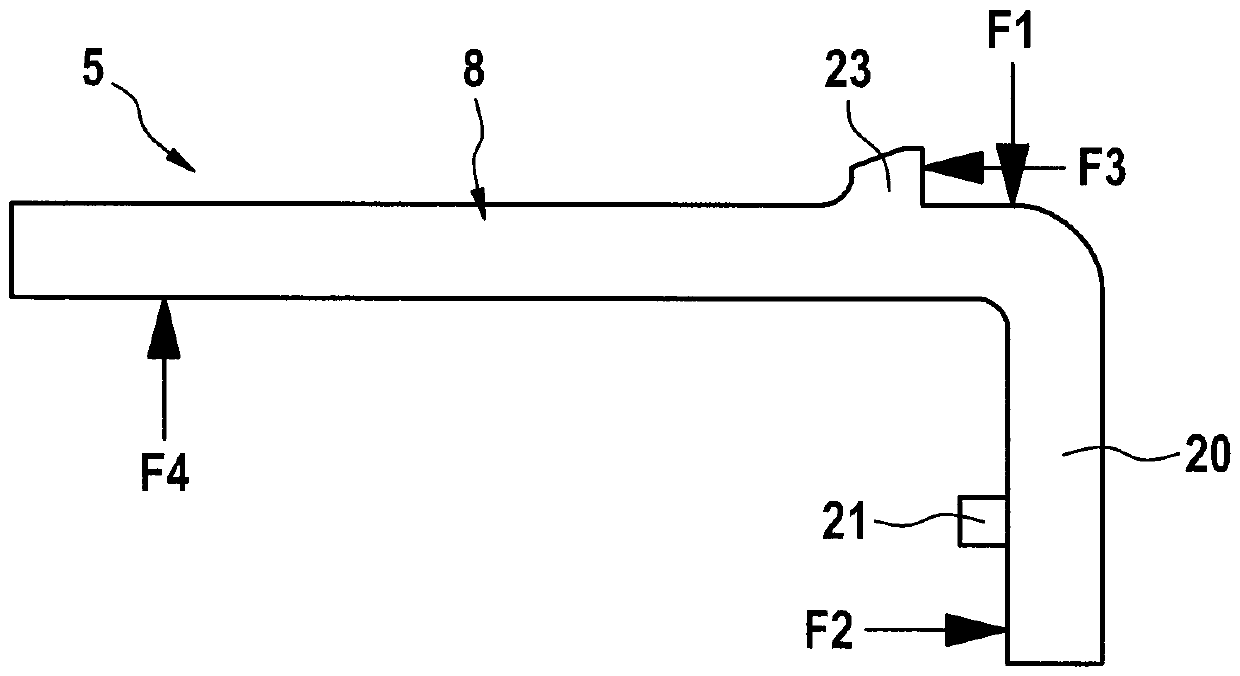

[0045] The temperature sensor 4 for detecting the temperature of the conductor 2 of the coil winding 16 is not connected, for example glued, to the conductor 2 of the coil winding 16 , as in the prior art, but via a support 5 clamping force is pressed onto the conductor 2 of the coil winding 16 . The coil winding 16 comprises a plurality of electrical conductors 2 wound around the sheet pack 3 so that the coil winding 16 is produced by winding the sheet pack 3 with the conductors 2 . The temperature sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com