Method for calculating gas content of thin seam

A technology with gas content and thin coal seam, applied in the field of coalbed methane exploration and development, it can solve the problems of many types of parameters, small scope of application of models, large volume of data, etc., and achieves simplified formula form and parameters, widely applicable value, and accurate prediction. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe in detail the embodiments of the present invention in conjunction with the accompanying drawings.

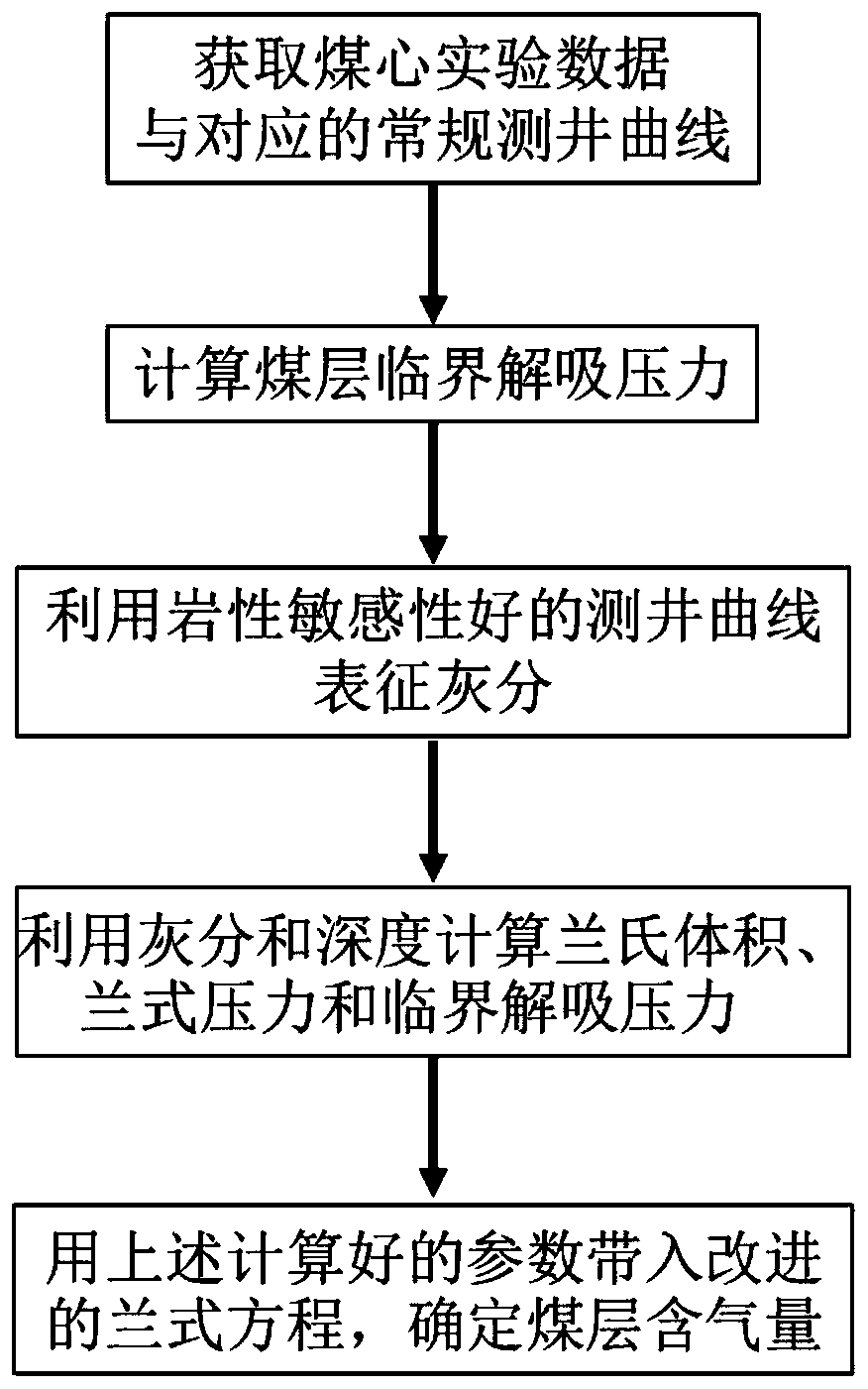

[0055] see figure 2 , the embodiment of the present invention provides a method for determining the gas content of a thin coal seam, which is carried out according to the following steps:

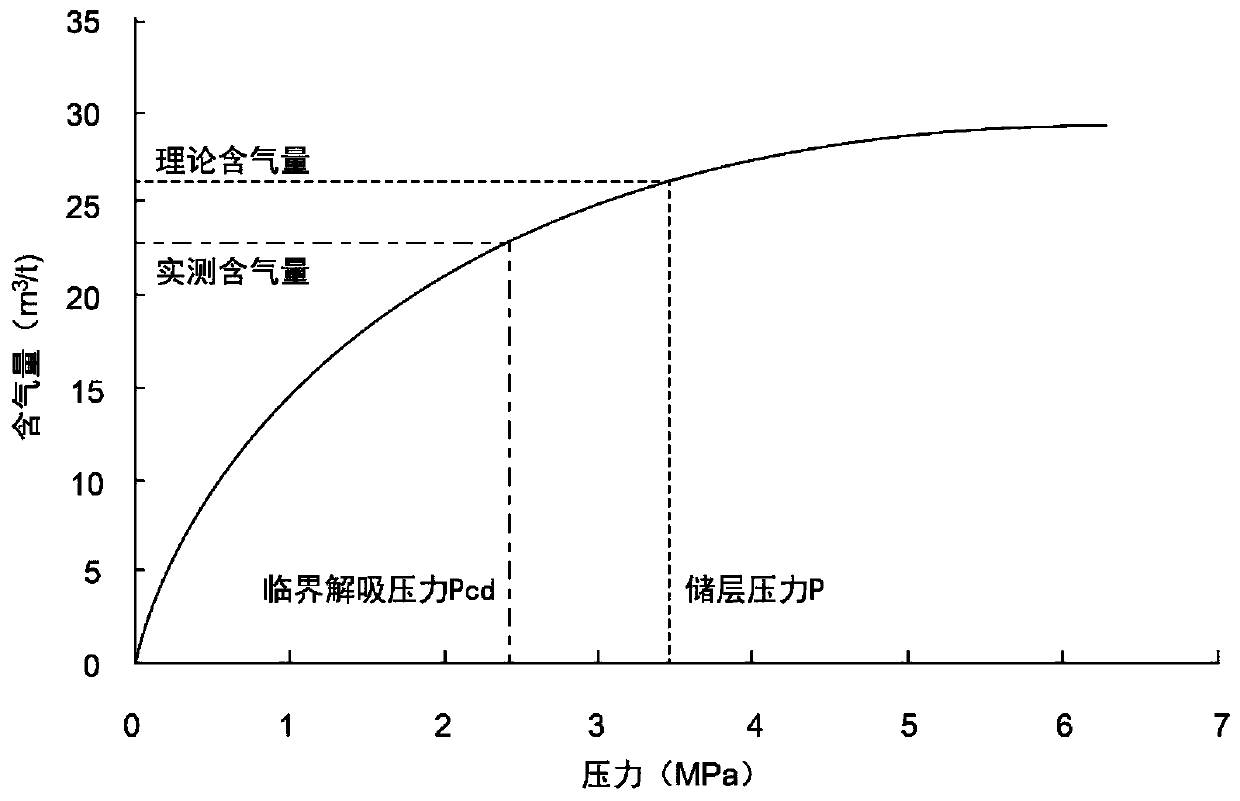

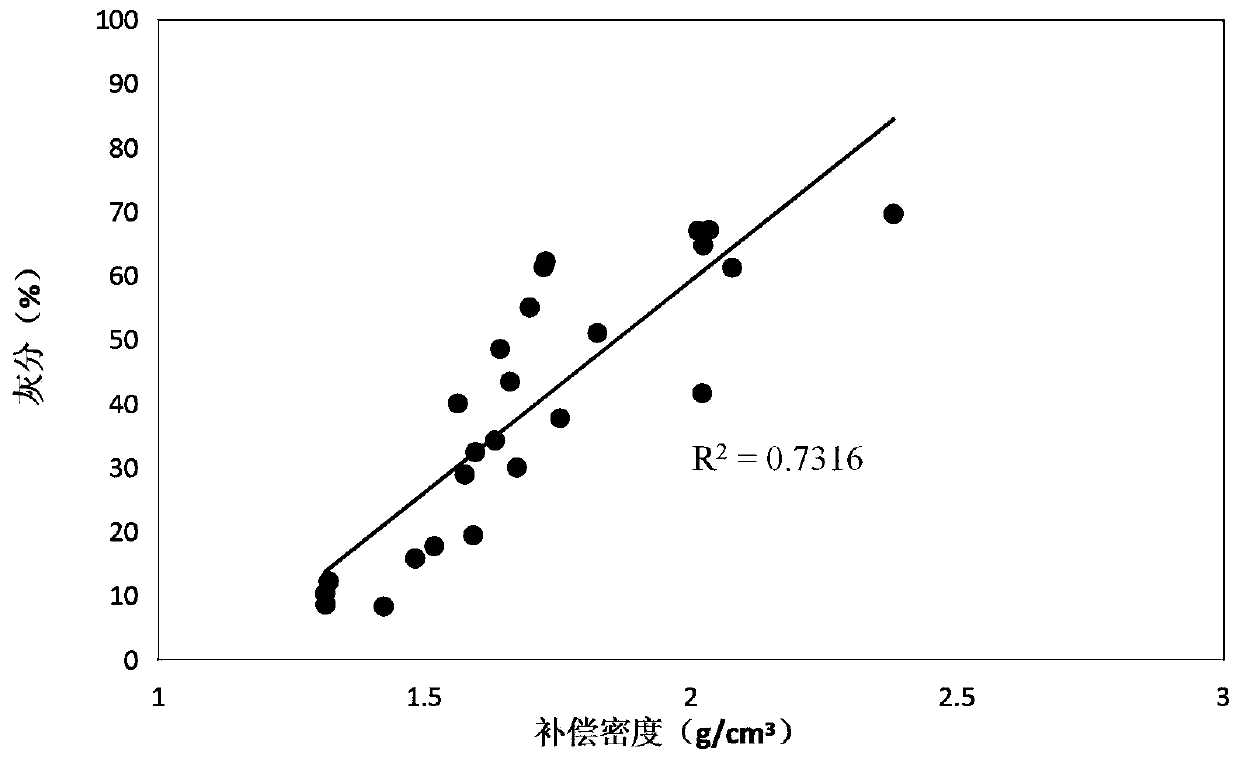

[0056] Step 1. Evenly select 25 core samples from 10 core wells in the Bowen Basin block of Australia, and follow the "Methods for Determination of Coalbed Gas Content GB / T19559-2008", "Industrial Analysis Methods for Coal GB / T212-2008" and "High Pressure of Coal Isotherm adsorption test method GB / T19560-2008"The process stipulated in the standard conducts experimental analysis on coal core samples, including gas content, industrial components and isothermal adsorption tests, to obtain the measured gas content G, ash content Aad, and Rankine volume V L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com