Based on ti 3 c 2 Thrombin aptamer sensor and preparation method thereof

An aptamer sensor and thrombin technology, which is applied in instruments, scientific instruments, fluorescence/phosphorescence, etc., can solve the problems of complex and time-consuming reactions, difficult preparation and storage of antibodies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

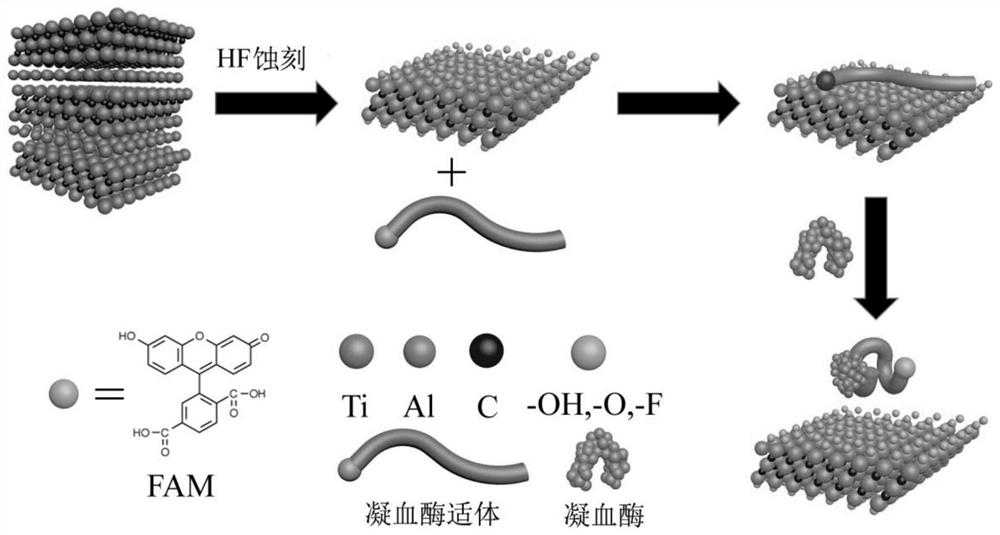

[0039] The present invention also provides a Ti-based 3 C 2 The preparation method of the thrombin aptamer sensor comprises the following steps:

[0040] (1) Monolayer Ti 3 C 2Preparation of:

[0041] Ti is prepared by sintering a mixture of titanium powder, aluminum powder, and graphite under argon 3 AlC 2 , will Ti 3 AlC 2 The powder was added to the LiF / HCl solution for etching under continuous stirring. After the reaction was complete, the acidic mixture was washed with ultrapure water by repeated centrifugation until the pH of the mixture exceeded 5. Finally, the slurry was sonicated and centrifuged to obtain a monolayer Ti 3 C 2 solution;

[0042] (2) Bind fluorescein-labeled thrombin aptamer to Ti 3 C 2 surface:

[0043] Add the fluorescein-labeled thrombin aptamer to the Ti prepared in step (1) at room temperature 3 C 2 In solution, after the reaction is complete, the composition is based on Ti 3 C 2 Thrombin aptamer sensor.

[0044] Preferably, the m...

Embodiment 1

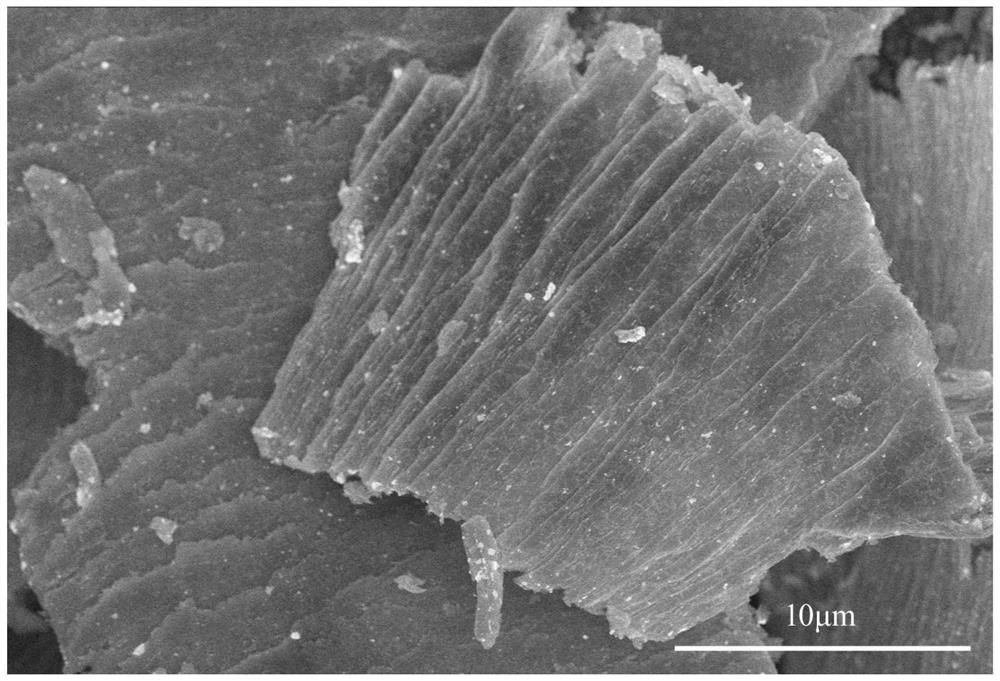

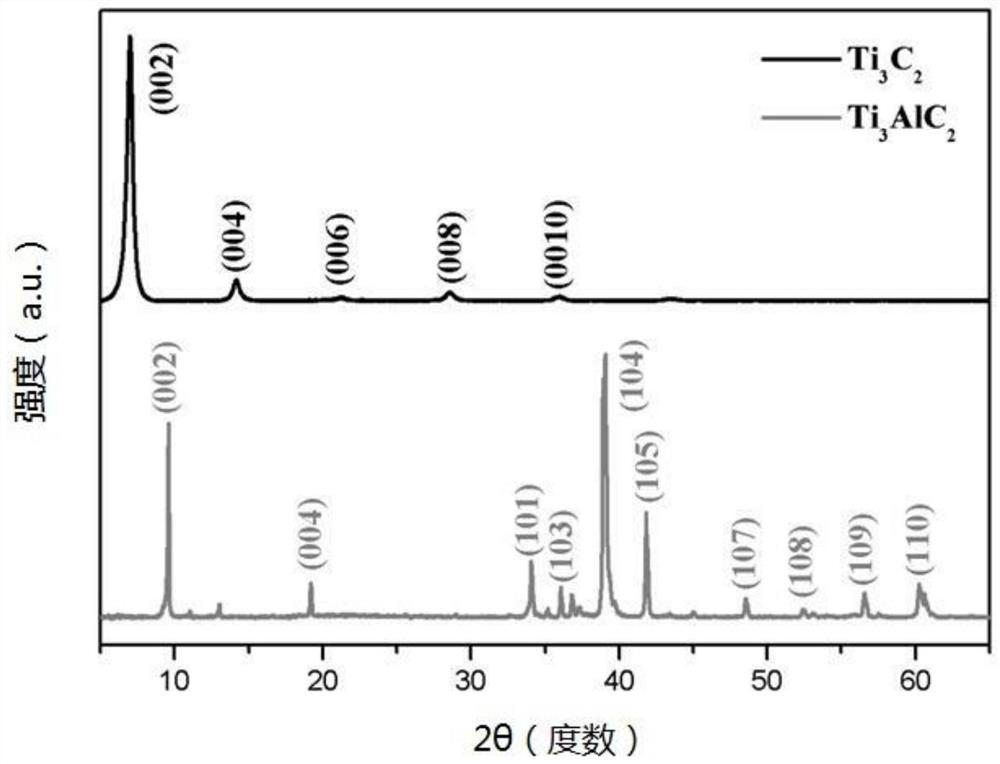

[0062] 1) Monolayer Ti 3 C 2 Synthesis: Ti was prepared by sintering a mixture of 7.368g titanium powder, 1.523g aluminum powder and 1.109g graphite under argon at 1650°C for 2 hours 3 AlC 2 . Fired Ti 3 AlC 2 The powder was ground in a mortar and passed through a 400-mesh sieve. 1gTi 3 AlC 2 It was added into a 12M LiF / 9M HCl solution for etching under continuous stirring, and reacted at room temperature for 24 hours. After the etching was completed, the centrifugation was repeated, and the mixture was washed with ultrapure water at 8000 rpm for 5 minutes per cycle until the pH of the mixture exceeded 5. Finally, the slurry was sonicated for more than 10 min and centrifuged at 3500 rpm for 1 h to obtain monolayer Ti 3 C 2 solution. To confirm Ti 3 C 2 concentration, filter 10mL Ti with a cellulose membrane with a pore size of 0.22 μm 3 C 2 Dispersions. Ti 3 C 2 After drying, the Ti 3 C 2 The film was peeled off and weighed, and Ti was calculated as 3 C 2...

Embodiment 2

[0067] 1) Monolayer Ti 3 C 2 Synthesis of Ti: Ti was prepared by sintering a mixture of 3.684 g titanium powder, 0.762 g aluminum powder and 0.555 g graphite at 1650 °C under argon for 2 hours 3 AlC 2 . Fired Ti 3 AlC 2 The powder was ground in a mortar and passed through a 400-mesh sieve. 1gTi 3 AlC 2 Add it into 8M LiF / 6M HCl solution under continuous stirring for etching, and react at room temperature for 24 hours. After the etching was completed, the centrifugation was repeated, and the mixture was washed with ultrapure water at 8000 rpm for 5 minutes per cycle until the pH of the mixture exceeded 5. Finally, the slurry was sonicated for more than 10 min and centrifuged at 3500 rpm for 1 h to obtain monolayer Ti 3 C 2 solution. To confirm Ti 3 C 2 concentration, filter 10mL Ti with a cellulose membrane with a pore size of 0.22 μm 3 C 2 Dispersions. Ti3 C 2 After drying, the Ti 3 C 2 The film was peeled off and weighed, and Ti was calculated as 3 C 2 co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com