A positioning and installation fixture for knock sensor

A knock sensor, positioning and installation technology, applied in the direction of machine/structural component testing, instruments, measuring devices, etc., can solve the problem of damage to other parts of the engine, the installation of knock sensors is not suitable, and the direction of manual fixation cannot be unified, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and implementation.

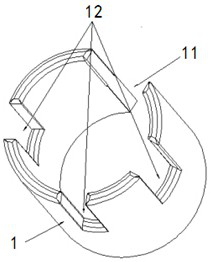

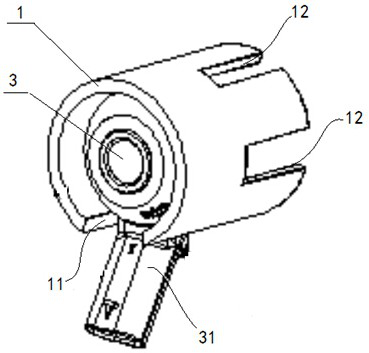

[0022] see figure 1 and figure 2 , a positioning and installation fixture for a knock sensor is shown, including a fixture body 1, which is characterized in that: the fixture body 1 is cylindrical and one side is provided with a limit notch 11 passing through the cylinder. One end of the clamp body 1 is provided with a plurality of bayonet slots 12 . This positioning installation fixture is an integral structure. Through the bayonet design, it is fixed on the engine by the ribs of the engine block. The limit notch is used to limit the direction of the harness connector of the knock sensor to ensure the consistency of orientation. During the tightening process, the wire harness connector is guaranteed not to rotate through the limiting action of the limiting notch.

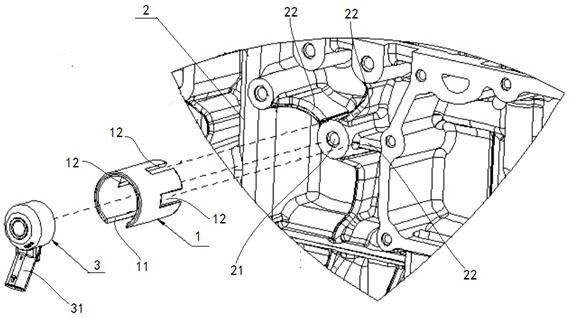

[0023] see image 3 and Figure 4 , the plurality of bayonet sockets 12 on one end of the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com