Teding and air drying device for rice

An air-drying device and tumbling technology, which is applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of low tumbling efficiency and long time, and achieve high tumbling efficiency, avoid shelling, and accelerate air-drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

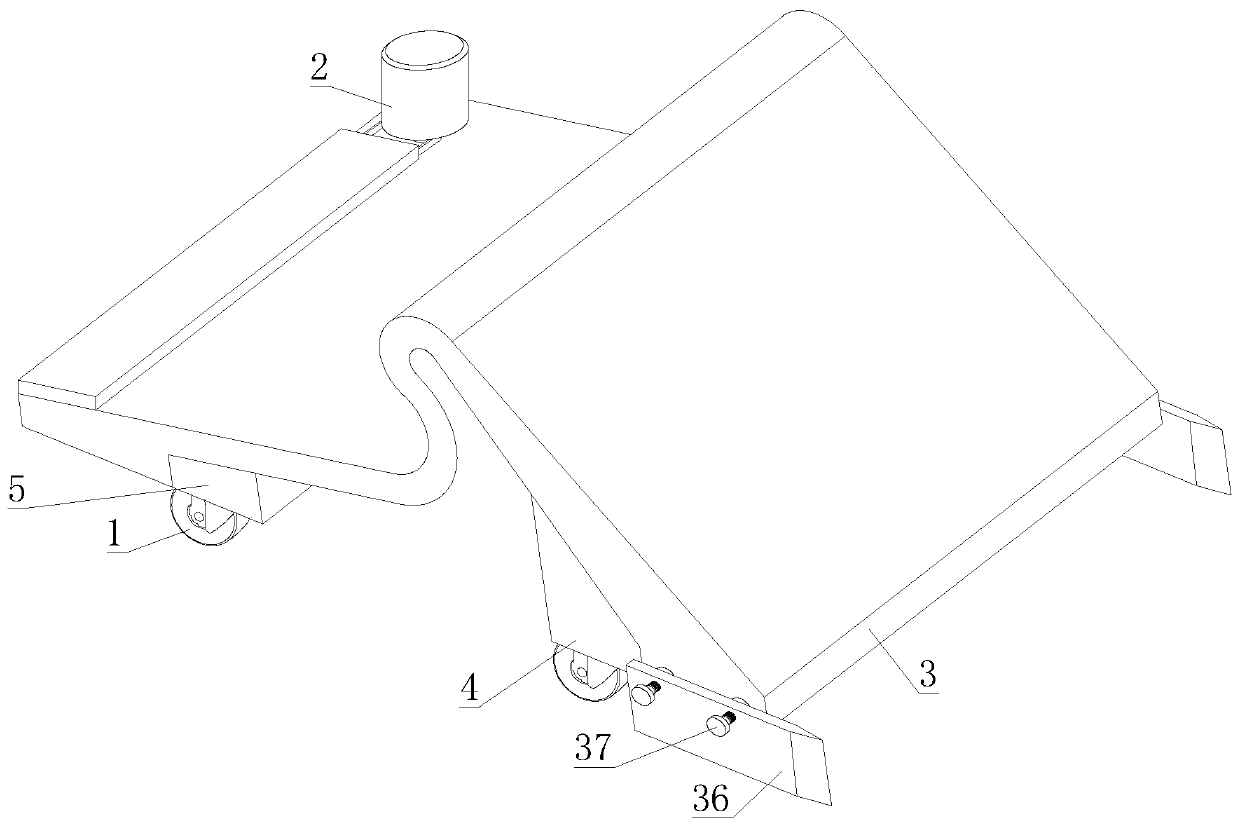

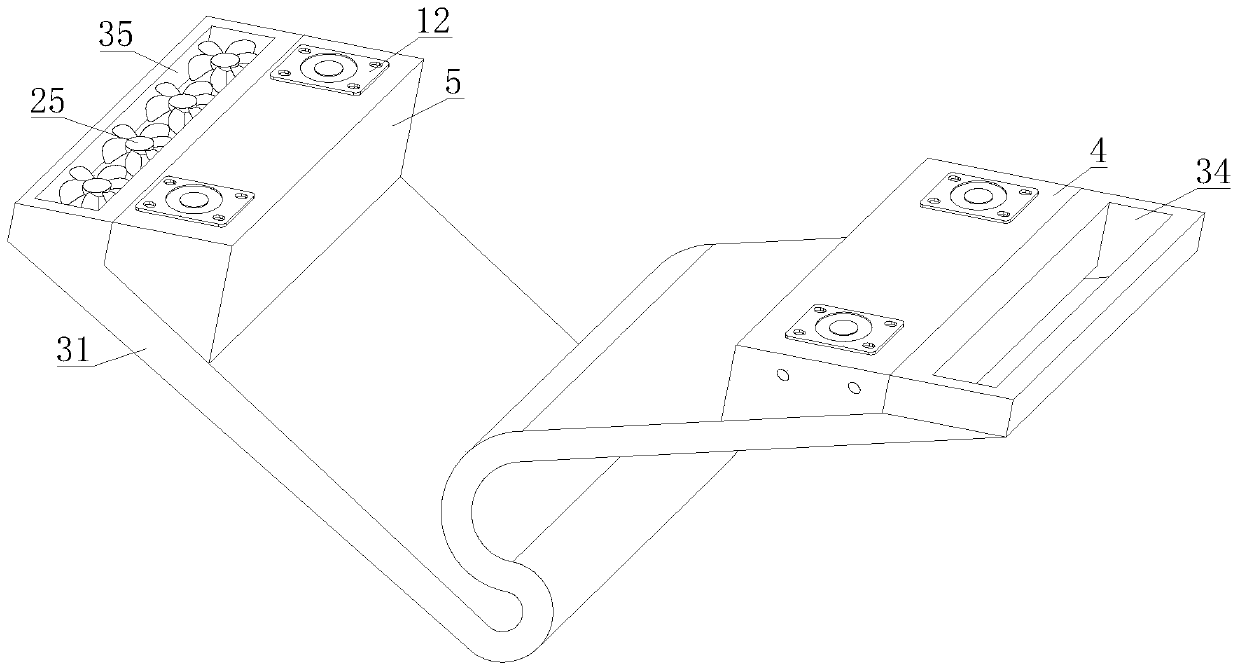

[0025] see Figure 1-4 , a rice drying device, comprising a walking mechanism 1, a suction mechanism 2, a device body 3, a front mounting plate 4 and a rear mounting plate 5, the front end of the device body 3 is welded with a front mounting plate 4, and the rear end of the device body 3 A rear mounting plate 5 is installed, and the lower end of the front mounting plate 4 and the rear mounting plate 5 is equipped with a traveling mechanism 1, and the rear end of the device main body 3 is equipped with a suction mechanism 2; the device main body 3 includes a cylinder 31, an air duct 33, Feed port 34, discharge port 35 and electric heater 32, the middle part of cylinder body 31 is air duct 33, and air duct 33 is S-shaped, when device main body 3 walks on the top of paddy rice by walking mechanism 1, feed port 34 and the discharge port 35 are all facing the ground, and move forward with the device body, the feed port 34 absorbs the rice into the air duct 33, and the electric heat...

Embodiment 2

[0029] see Figure 7, a rice drying device, comprising a walking mechanism 1, a suction mechanism 2, a device body 3, a front mounting plate 4 and a rear mounting plate 5, the front end of the device body 3 is welded with a front mounting plate 4, and the rear end of the device body 3 A rear mounting plate 5 is installed, and the lower end of the front mounting plate 4 and the rear mounting plate 5 is equipped with a traveling mechanism 1, and the rear end of the device main body 3 is equipped with a suction mechanism 2; the device main body 3 includes a cylinder 31, an air duct 33, Feed port 34, discharge port 35 and electric heater 32, the middle part of cylinder body 31 is air duct 33, and air duct 33 is U-shaped, when device main body 3 walks on the top of paddy by walking mechanism 1, feed port 34 and the discharge port 35 are all facing the ground, and move forward with the device body, the feed port 34 absorbs the rice into the air duct 33, and the electric heater 32 he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com