Automatic get-on system and excavator

An excavator, automatic technology, applied in the direction of earth mover/excavator, construction, etc., can solve the problems of the driver's difficulty in getting on the car, stepping on the empty injury, etc., so as to avoid climbing, easy to get on the car, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

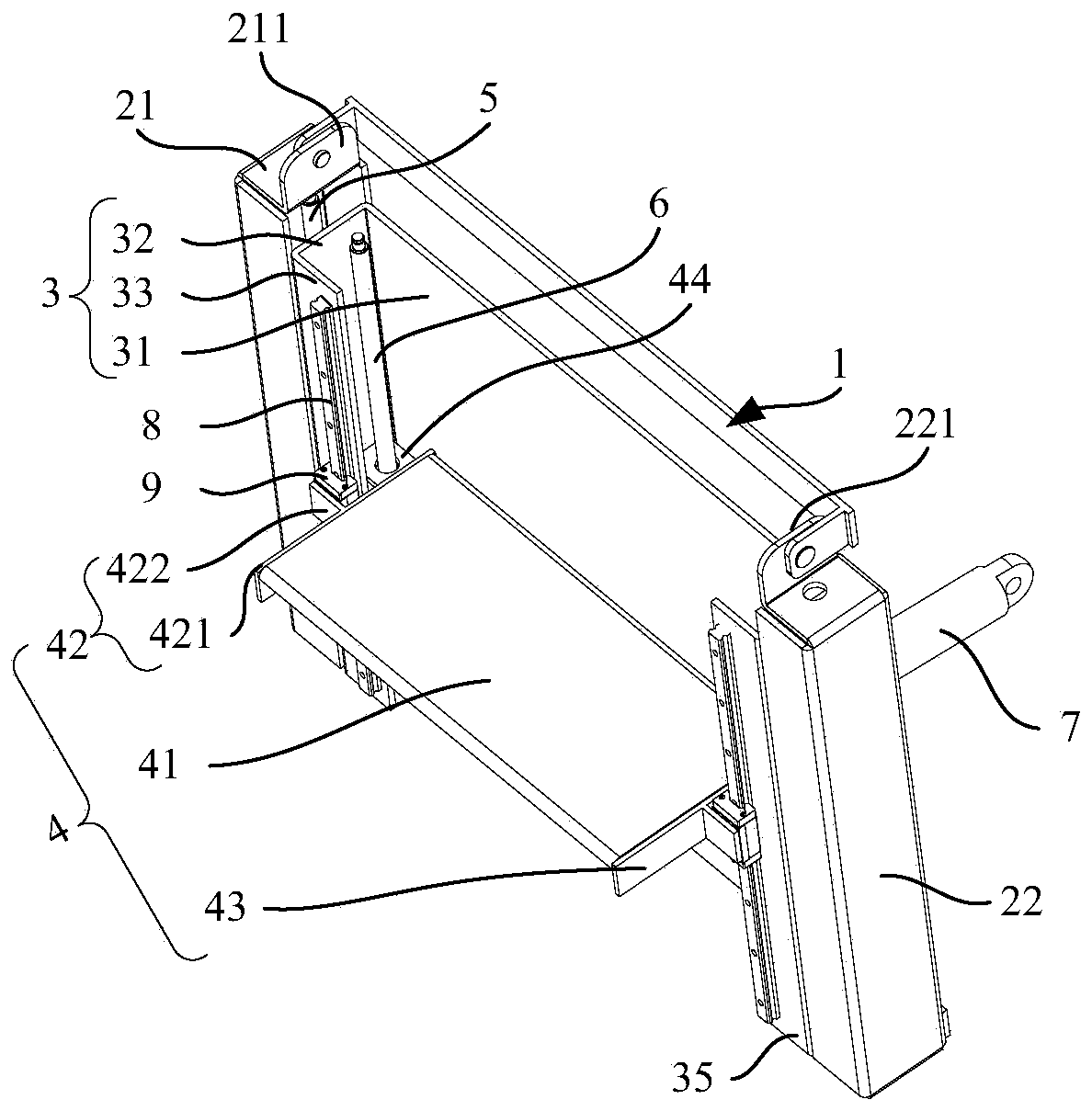

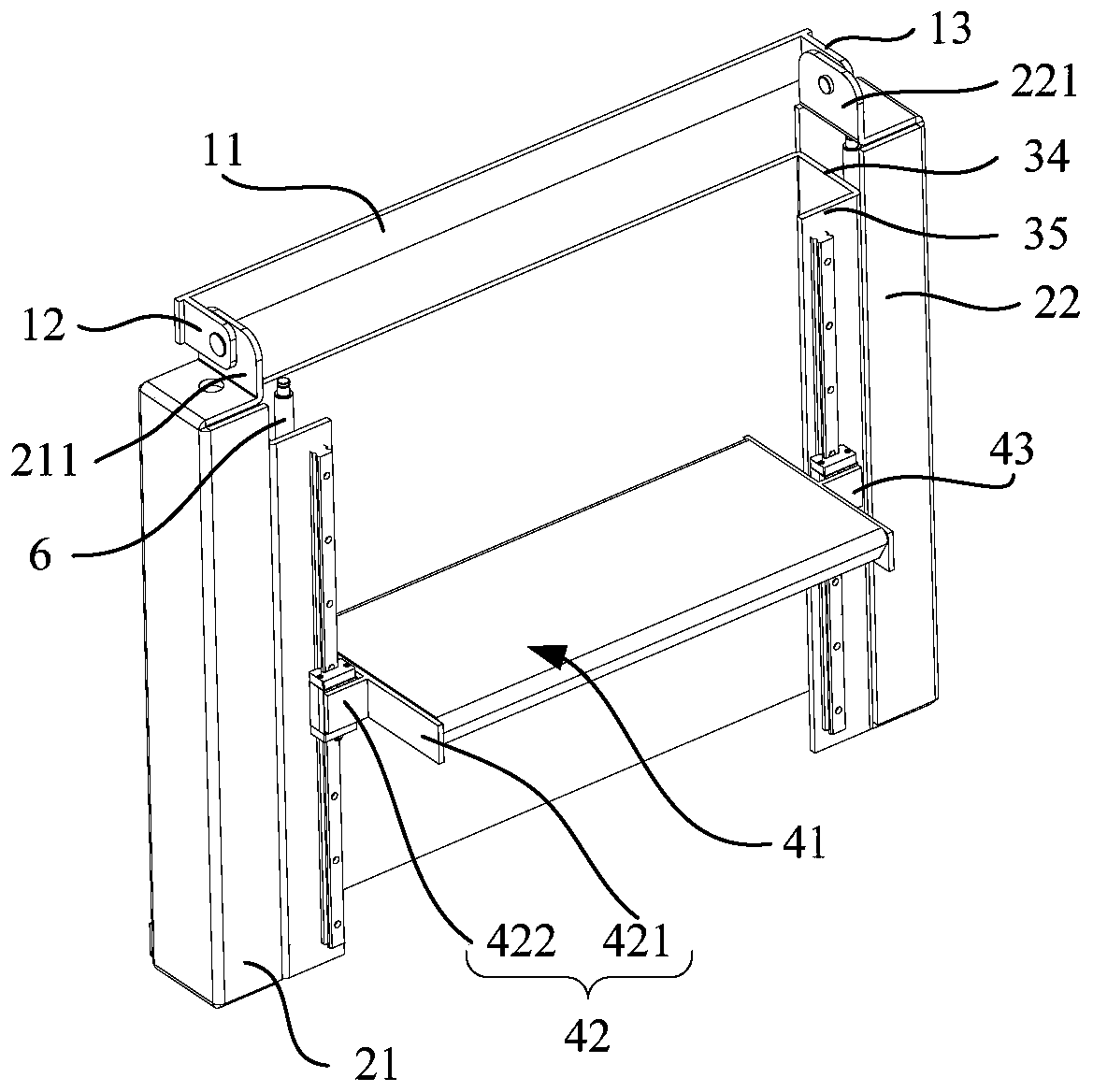

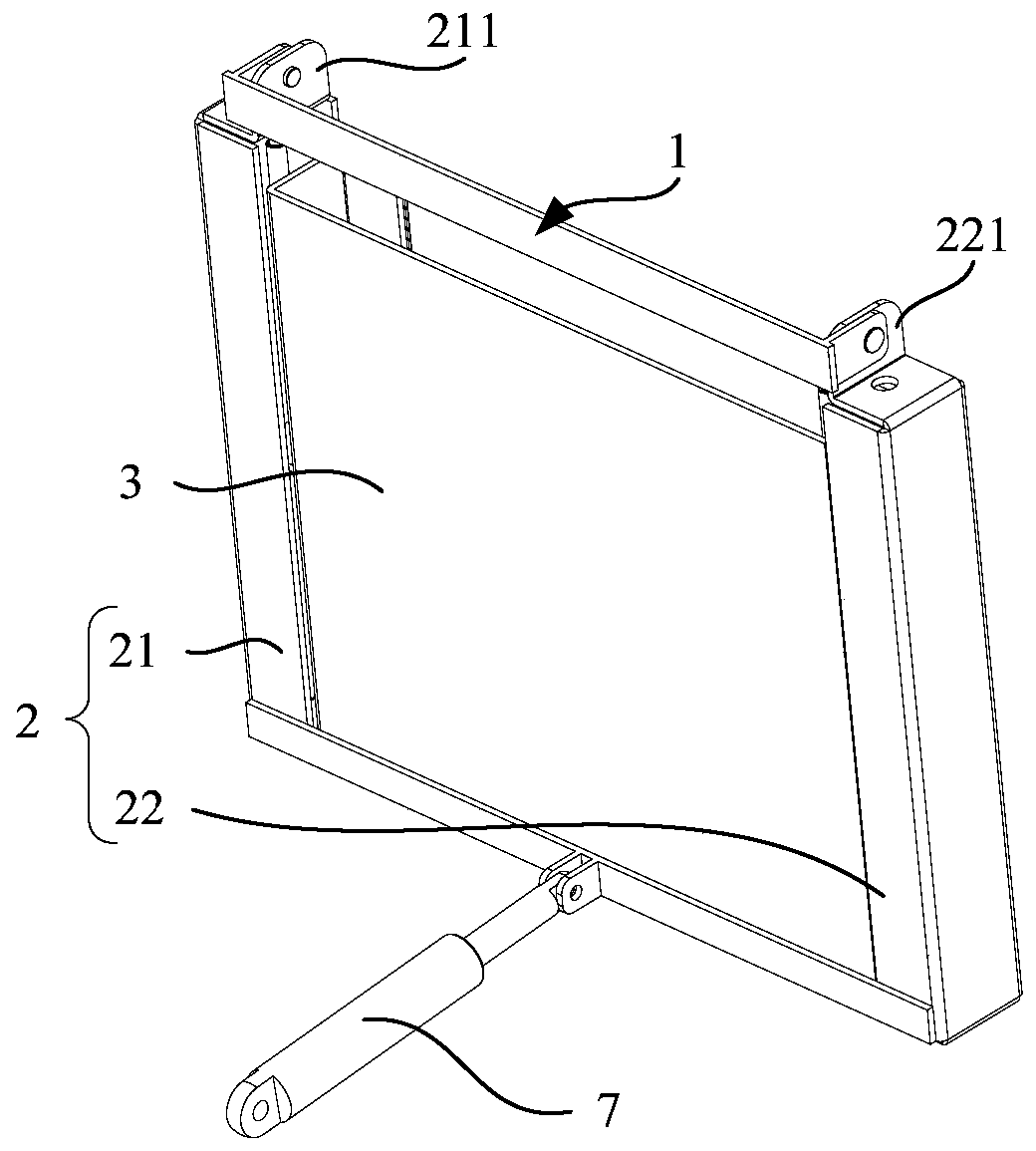

[0045] see Figure 1 to Figure 3 As shown, the embodiment of the present application provides an automatic boarding system for an excavator, the excavator includes a vehicle body, the vehicle body includes a cab, and the automatic boarding system includes: a first support member 1, a second support member 2, The third supporting member 3, the carrying member 4, the first driving device, the first transmission mechanism 5, the second driving device, the second transmission mechanism 6 and the driving mechanism 7;

[0046] Wherein, the first supporting member 1 is fixedly arranged on the vehicle body of the excavator; the second supporting member 2 is rotationally connected with the first supporting member 1 (for example, through a pin shaft), of course, it is not limited thereto; the driving mechanism 7 is arranged on the excavator On the vehicle body, the driving mechanism 7 can be arranged especially under the cab, and the driving mechanism 7 is connected with the second supp...

Embodiment 2

[0097] The embodiments of the present application provide an automatic boarding system, which is an improvement on the basis of the first embodiment. For ease of understanding, the labels in the first embodiment can be used. Figure 1 to Figure 3 As shown, the automatic loading system is used for an excavator, the excavator includes a body, and the automatic loading system includes: a first support member 1, a second support member 2, a third support member 3, a bearing member 4, and a first drive device , the first transmission mechanism 5 and the drive mechanism 7;

[0098] The first support member 1 is fixed on the body of the excavator; the second support member 2 and the first support member 1 are rotatably connected through a rotating shaft, of course, not limited to this; the drive mechanism 7 is provided on the body of the excavator, and the drive mechanism 7 can especially be arranged below the cab, and the driving mechanism 7 is connected with the second supporting m...

Embodiment 3

[0102] The embodiments of the present application provide an automatic loading system, which is an improvement on the basis of the first embodiment. The automatic loading system is used for an excavator, and the excavator includes a body. The automatic loading system includes: provided on the body the bearing components and drive components;

[0103] It can be seen that the system can drive the carrying assembly to move relative to the vehicle body through the driving assembly, so that the driver or the like placed on the carrying assembly can ascend or descend.

[0104] Among them, the driving component can be two cylinders, both of which are fixed on the vehicle body, the bearing component can be a bearing plate, and the ends of the cylinder rods of the two cylinders are connected to the bearing plate, and with the expansion and contraction of the cylinder, the bearing plate can be move.

[0105] Of course, it is not limited to the above structure, and the drive assembly may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com