Energy-saving electronic cable winding device

A technology of winding device and cable, applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of complicated device, inconvenient to popularize and implement, increase manufacturing and production cost, etc. The effect of simplification, easy promotion and implementation, and reduction of manufacturing and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

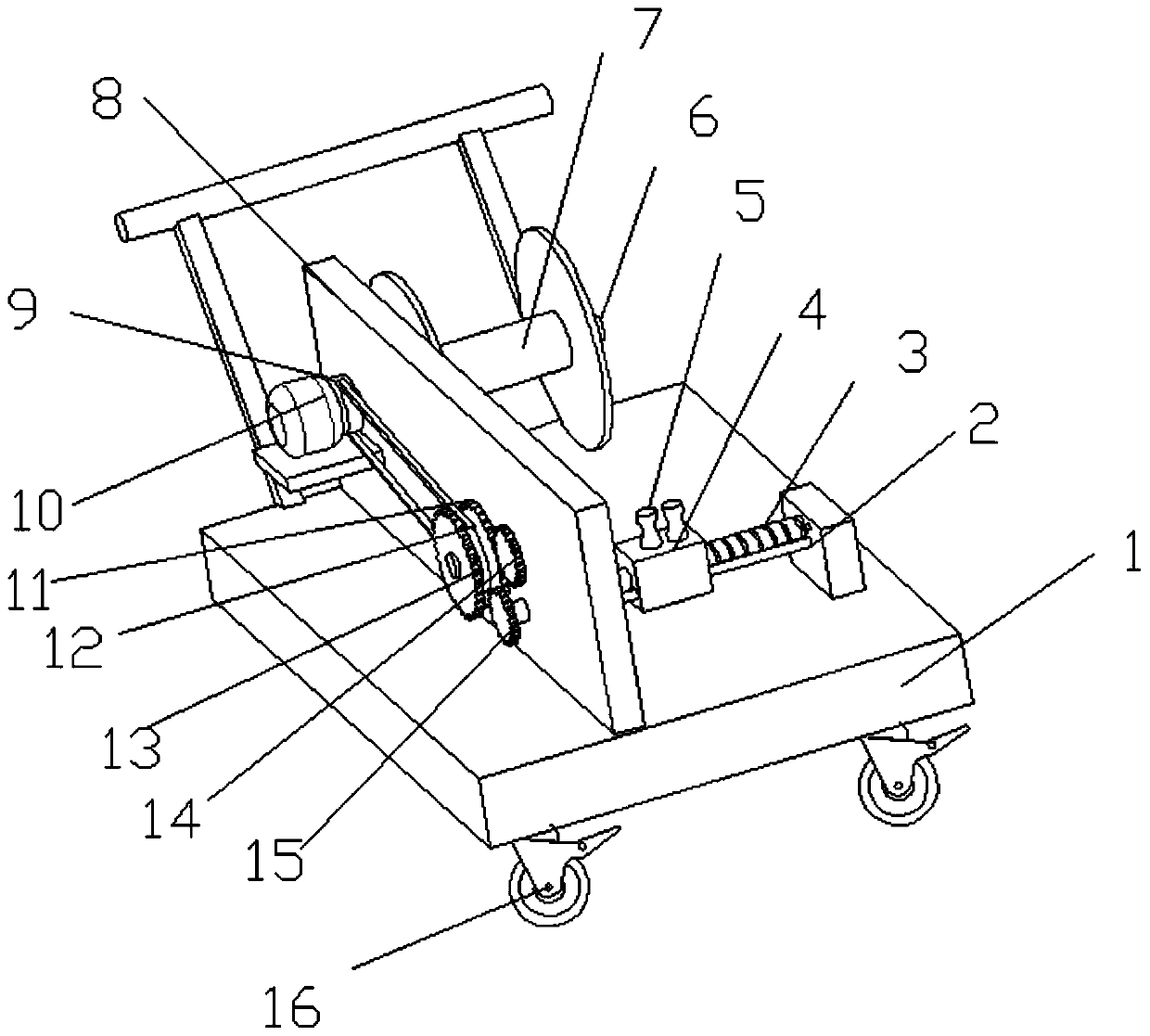

[0024] see Figure 1-2 , an energy-saving electronic cable winding device, comprising a base 1 and a cable roller 7, the four corners of the bottom of the base 1 are provided with universal wheels 16, the universal wheels 16 are provided with clamping plates, and the clamping plates have Braking effect, the setting of universal wheel 16 facilitates the movement and fixing of base 1. The upper surface of the base 1 is fixedly provided with a support frame 8, and one end side wall of the support frame 8 is fixedly mounted with a motor 10, and the output shaft of the motor 10 is coaxially fixedly connected with a driving pulley 9 and a rotating shaft 6, and the rotating shaft 6 is located in the support frame 8. On the other side of the rotating shaft 6, a cable roller 7 is sheathed. The rotating shaft 6 has a polygonal column structure, thereby preventing the cable roller 7 from rotating on the rotating shaft 6 . The other end side wall of support frame 8 is provided with inne...

Embodiment 2

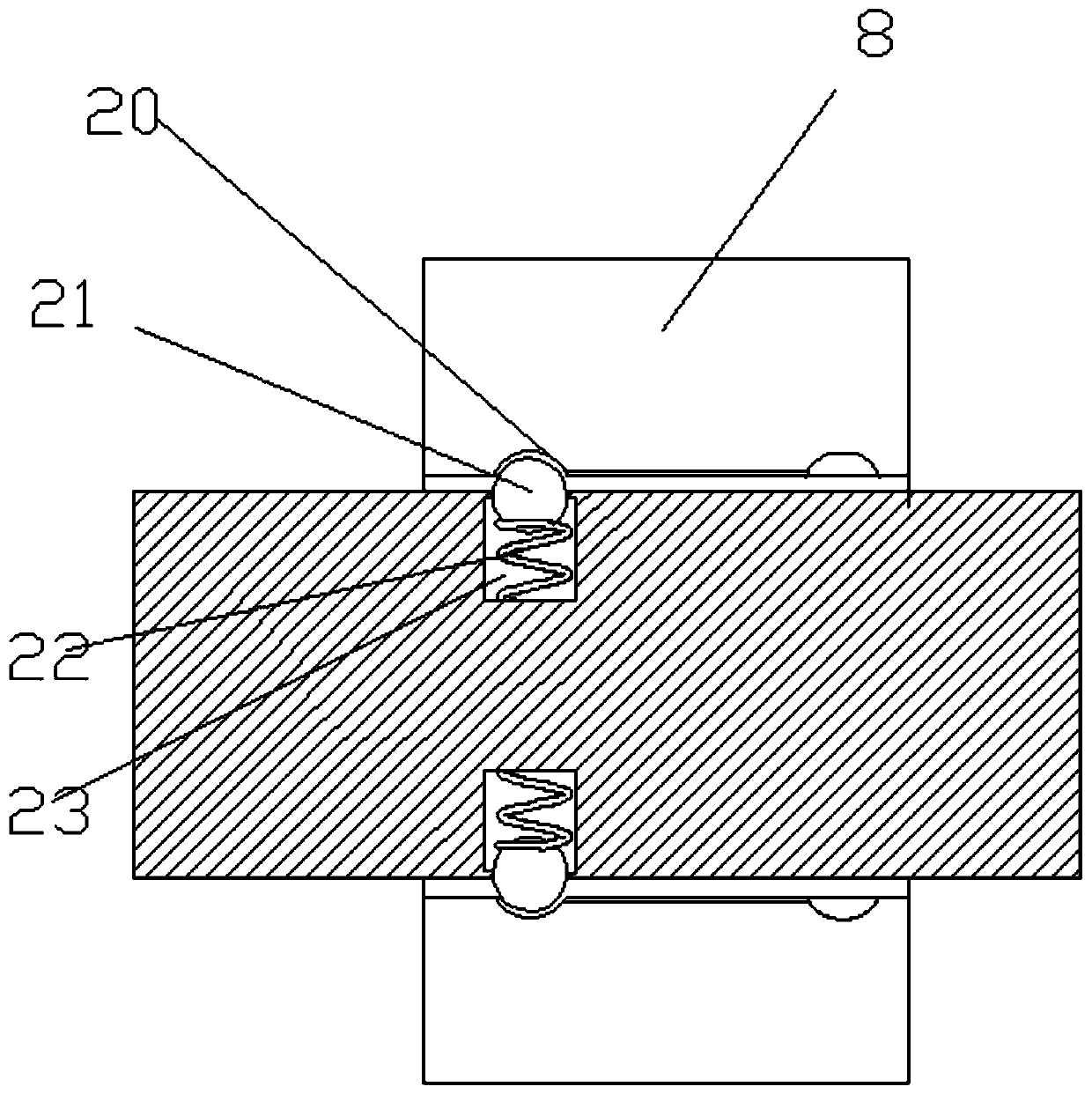

[0028] see image 3 , on the basis of Embodiment 1, the side wall of the sliding rod 17 is provided with a nesting groove 23, and the inside of the nesting groove 23 is slidingly nested with a ball 21, and the ball 21 can slide inside the nesting groove 23, and the nesting groove 23 is a cylindrical structure with a convex cross-section, thereby preventing the ball 21 from slipping out of the nesting groove 23. A spring 22 is placed inside the ball 21 inside the nesting groove 23, and the spring 22 makes the ball 21 slide outwards. The support frame 8 and There are two sets of grooves 20 inside the support seat, and the balls 21 are nested inside the 2, and the sliding rod 17 is subjected to the jacking force, so that the balls 21 are converted and slid inside the two grooves 20, thus avoiding the free movement of the rotating rod 19. The stability of the meshing of the driven gear 15 with the external driving gear 13 and the transmission gear 14 is ensured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com