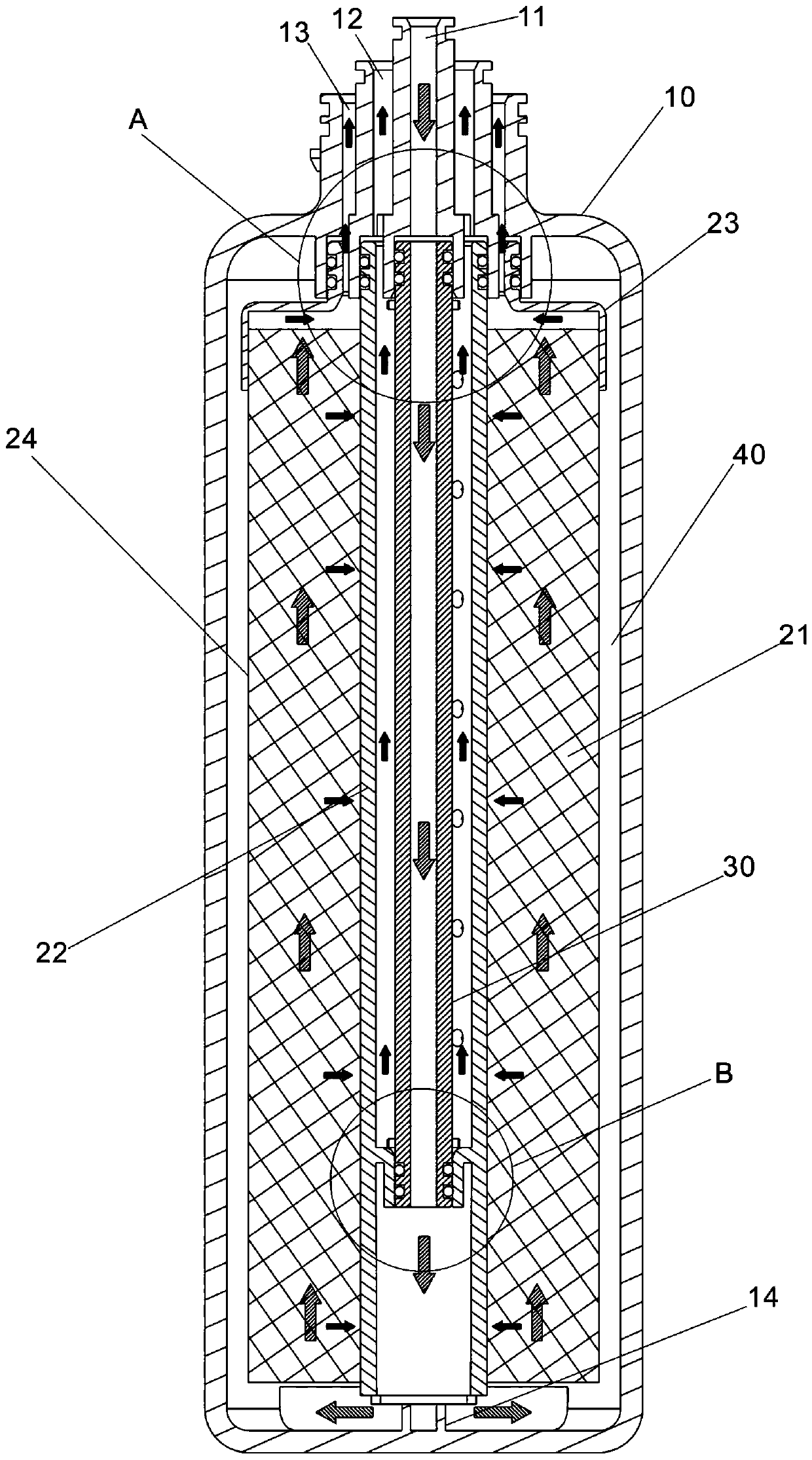

Filtering device and filtering system

A filter device and filter element technology, applied in chemical instruments and methods, water/sludge/sewage treatment, reverse osmosis, etc., can solve problems such as high TDS value, reduce excessive TDS value, reduce manufacturing cost, and reduce structural complexity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

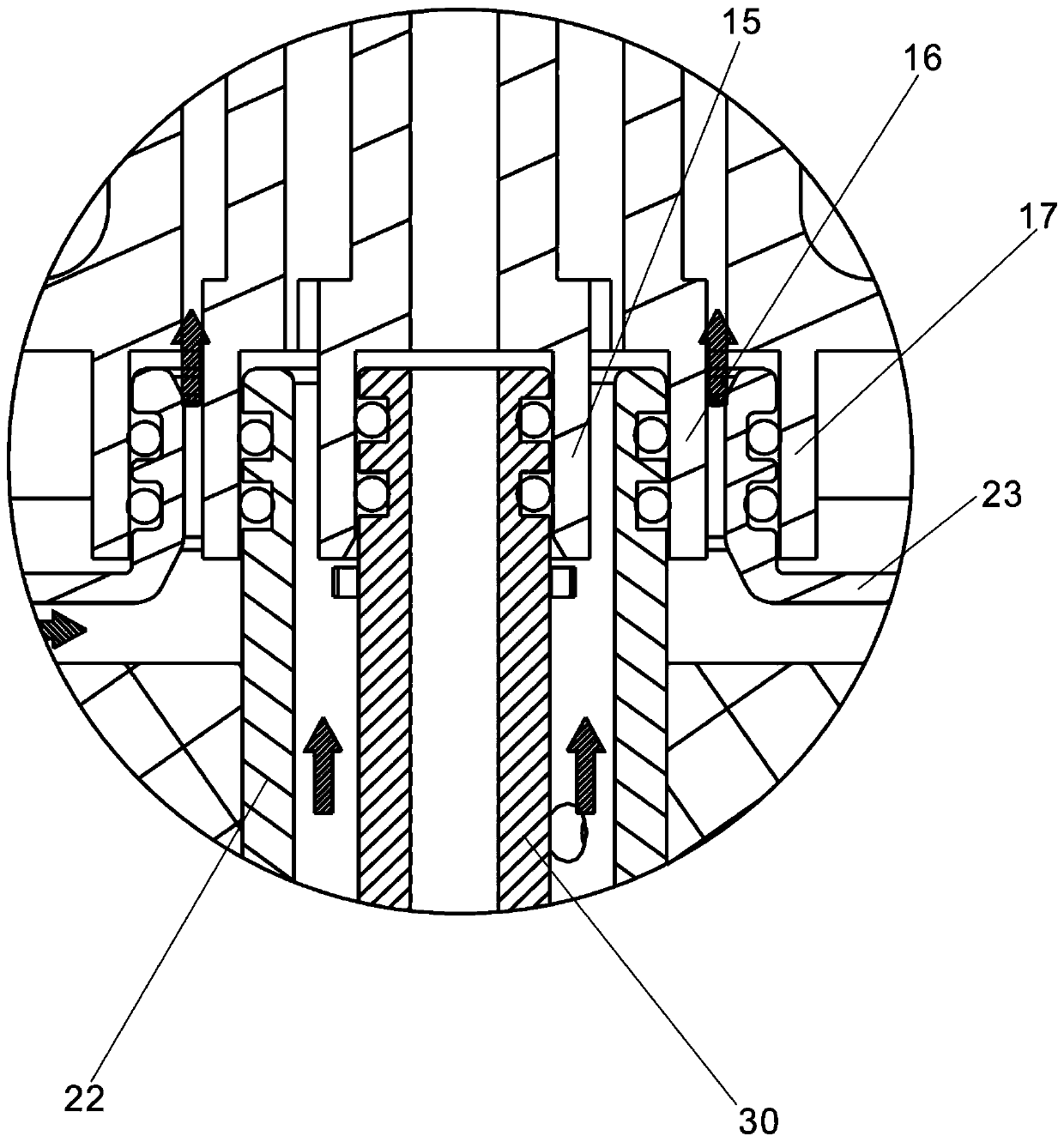

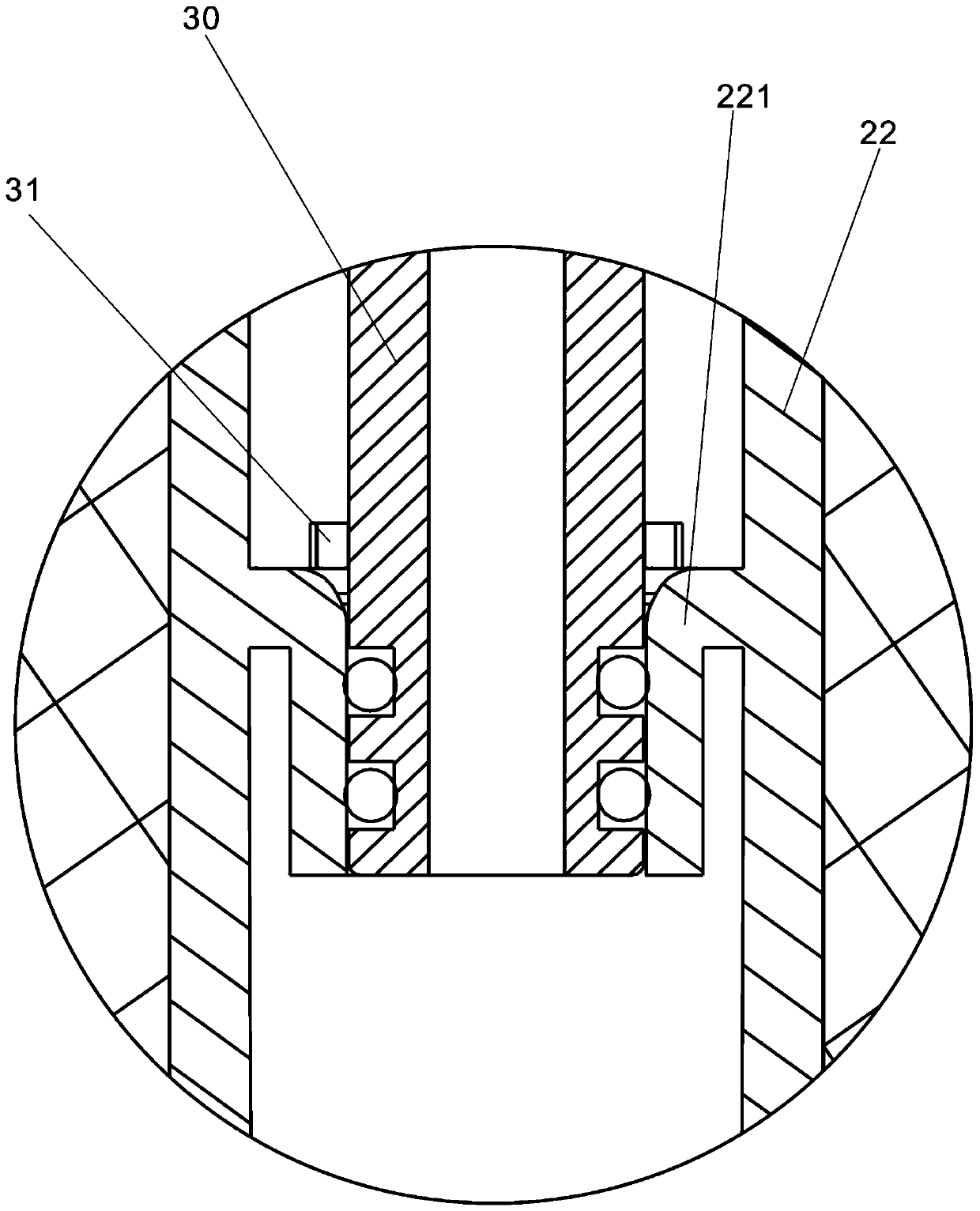

Method used

Image

Examples

Embodiment 2

[0060] The present invention also provides Embodiment 2, which is different from Embodiment 1 in that the structure of the water storage component is different. In Embodiment 2, the water storage component is an air bag water tank 41 arranged outside the casing 10 and communicated with the raw water inlet 11 , specifically, such as Figure 6 As shown, the air bag water tank 41 includes a water tank shell, and a cavity is formed inside the shell, and the cavity has an opening, and the opening is directly connected to the raw water inlet 11 on the shell 10, so that the raw water can reach the raw water inlet 11 At the same time, it can enter the cavity in the water tank shell at the same time. At the same time, an elastic film is arranged in the cavity, and the elastic film divides the cavity into a closed air cavity and a connection with the raw water inlet 11. Raw water enters the water storage chamber, and because there is a large pressure at the raw water end when the filter...

Embodiment 3

[0061] The present invention also provides Embodiment 3, which differs from Embodiment 2 in that the water storage component further includes a water storage cavity 42 , and the airbag water tank 41 communicates with the water storage cavity 42 . Specifically, such as Figure 7 As shown, the structure of the air bag water tank 41 is the same as that of Embodiment 2, and the structure of the water storage chamber 42 is the same as that of the raw water chamber 40 in Embodiment 1, but the water storage chamber 42 is a vacuum. The opening of the airbag water tank 41 is set to communicate with the top of the water storage chamber 42. When the filter device is running, the raw water enters the water storage chamber 42 after passing through the water inlet pipe 30, and then enters the water storage chamber of the airbag water tank 41 to compress the air. The volume of the cavity shrinks; when the filter device stops running, the pressure becomes unbalanced, and the air cavity recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com