Malfunction detection device for passenger conveyor

A technology for passenger conveyors, anomaly detection, used in transportation and packaging, escalators, etc., to solve problems such as injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

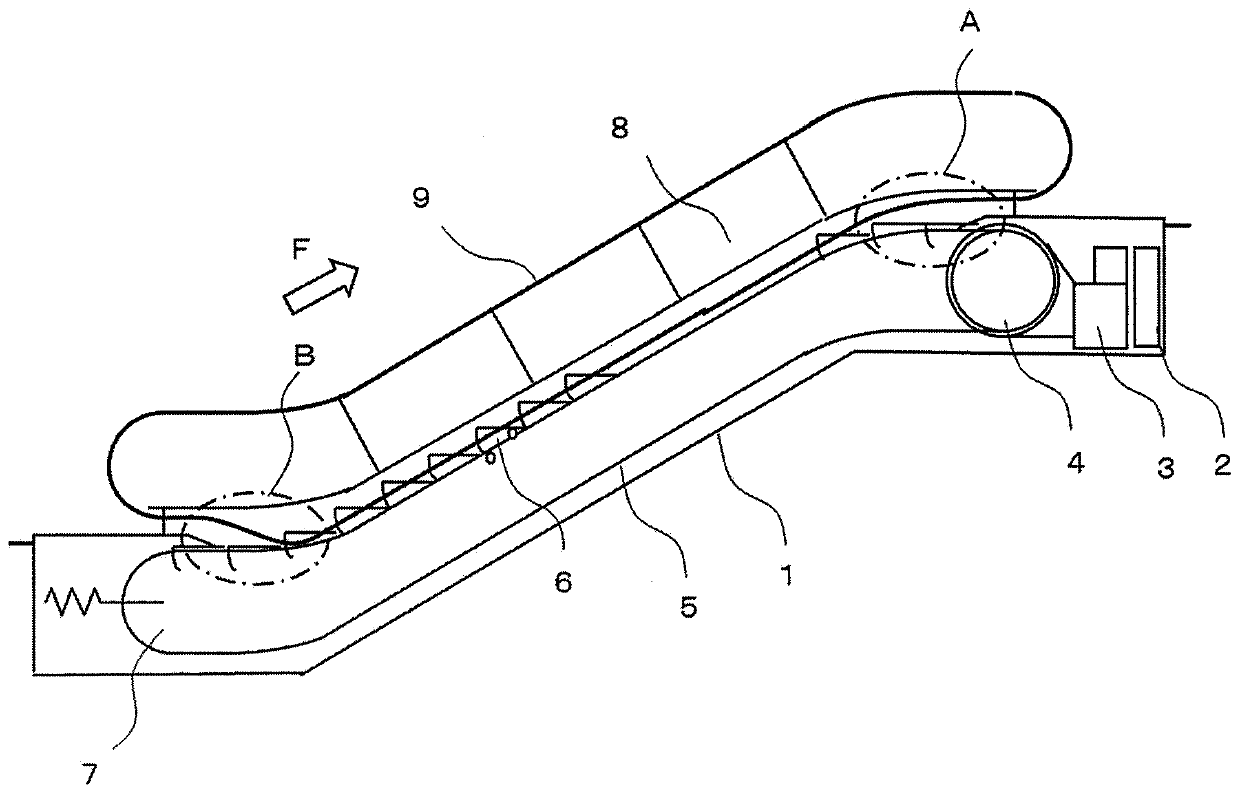

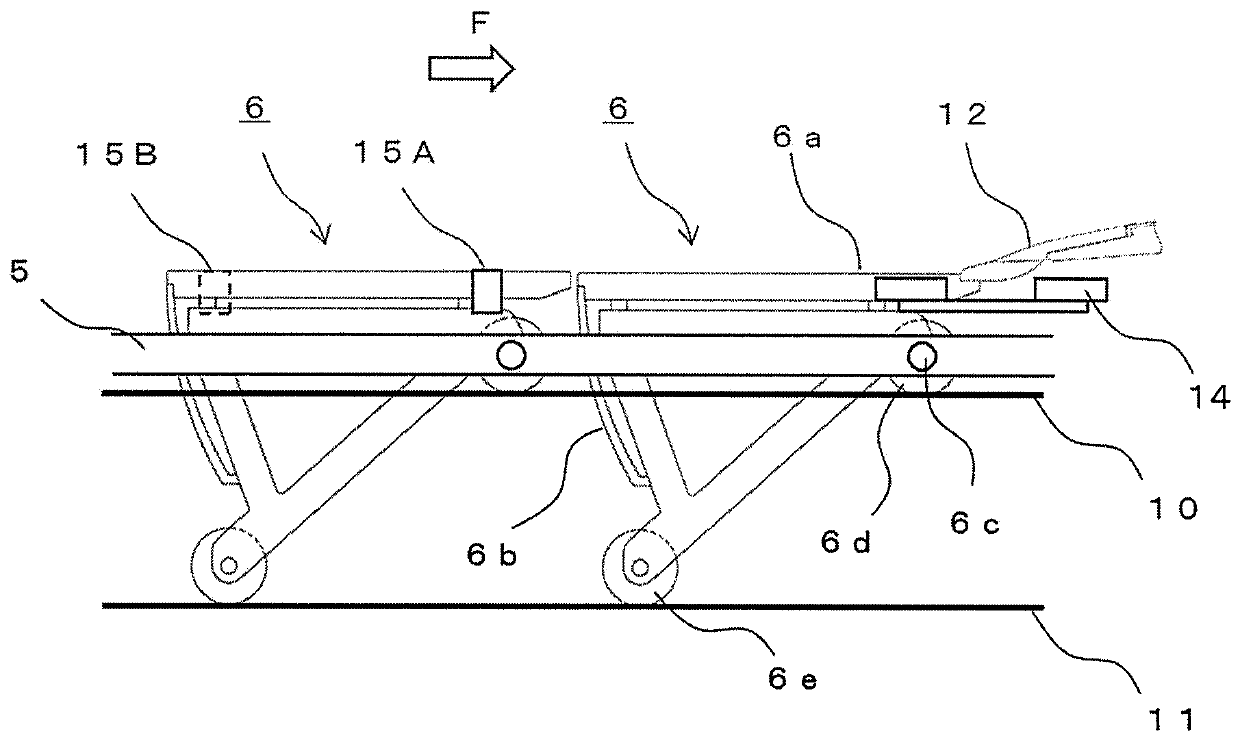

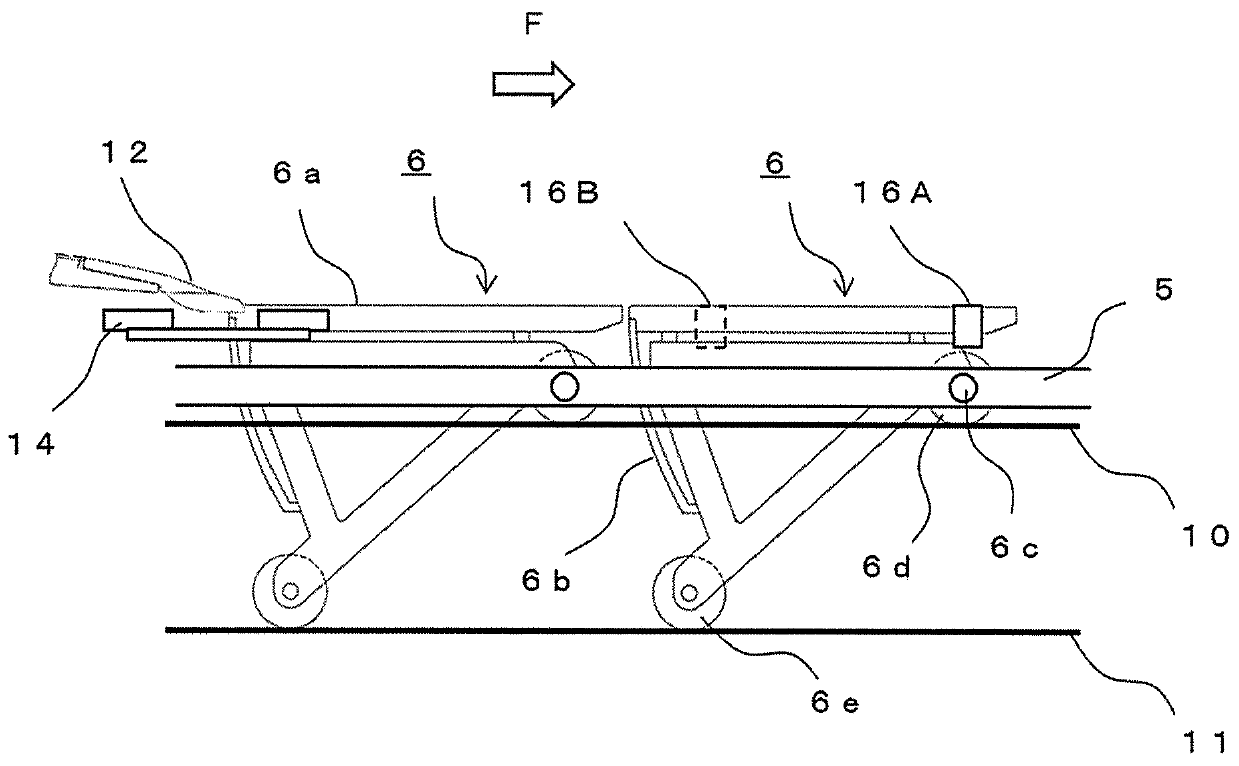

[0028] figure 1 It is a schematic diagram showing the passenger conveyor in which the abnormality detection device in Embodiment 1 of this invention is arrange|positioned. figure 2 is showing figure 1 A partial enlarged view of the horizontal portion A of the upper side, image 3 is showing figure 1 A partial enlarged view of the horizontal section B on the lower side of . also, Figure 4 is to be observed from above figure 2 The diagram of is arranged so that the direction of travel of the steps faces up and down.

[0029] like figure 1 As shown, the passenger conveyor has a truss 1, a control panel 2, a driving machine 3, a step sprocket 4 arranged on the upper reversing part, a step chain 5 wound on the step sprocket 4, a plurality of steps 6, and a lower reversing 7, a plurality of railings 8, and a moving handrail 9. The step sprocket 4 is rotated by the driving machine 3 whose operation is controlled by the control panel 2 . in addition, figure 1 One side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com