A five-axis stamping robot

A technology of a robot and a stamping mechanism, applied in the field of stamping mechanism, can solve the problem of inability to rotate a servo motor. The first sliding device that slides up and down. The first sliding device is provided with a second rotary servo motor along the front and rear directions. The rotating part of the second rotary servo motor is connected to the cross arm. The second sliding device, the mechanical arm is arranged in the chute and the mechanical arm is connected to the second sliding device, and the lower side of the end of the mechanical arm passes through the third rotation servo and other problems to achieve the effect of ensuring the stamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

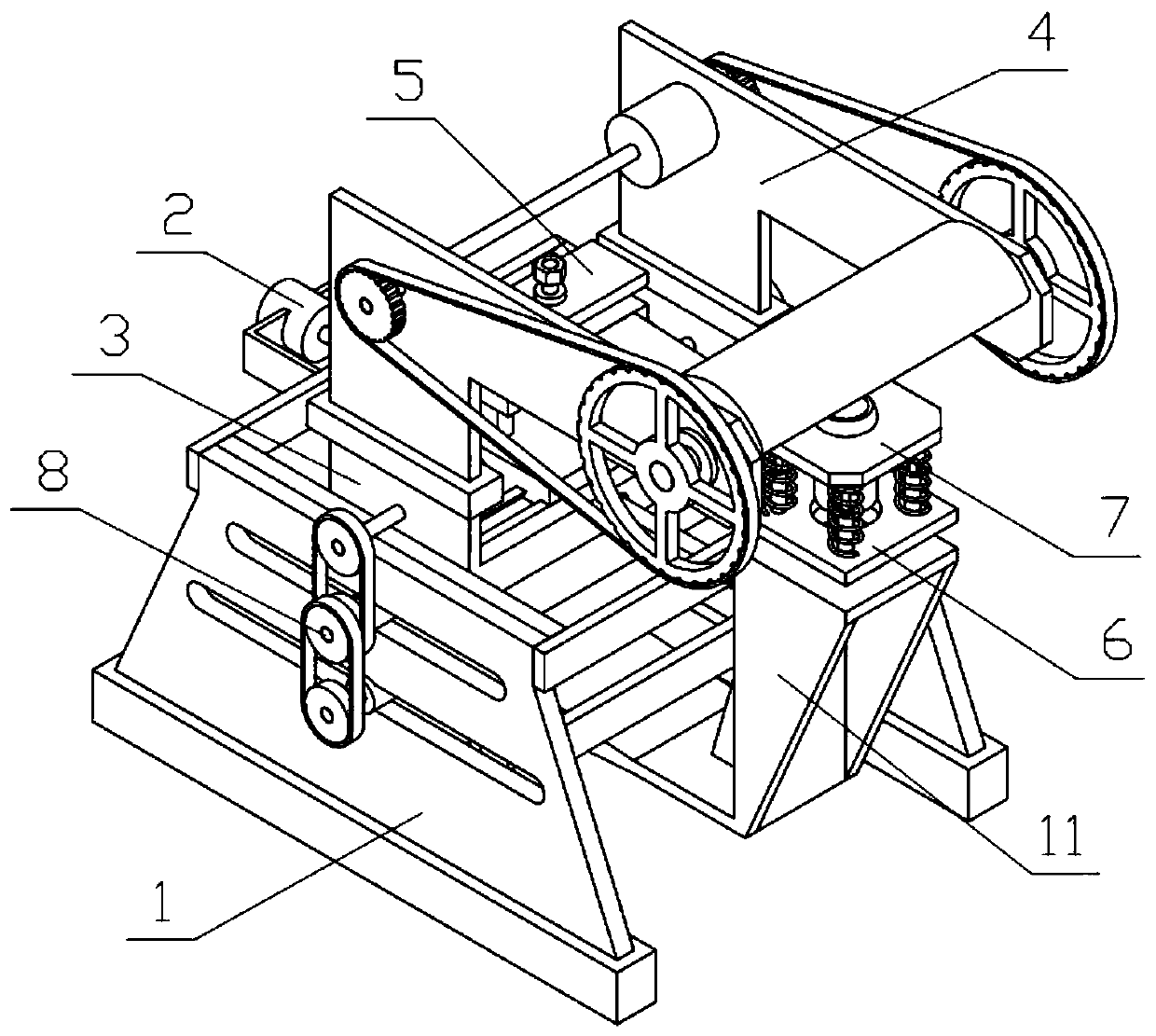

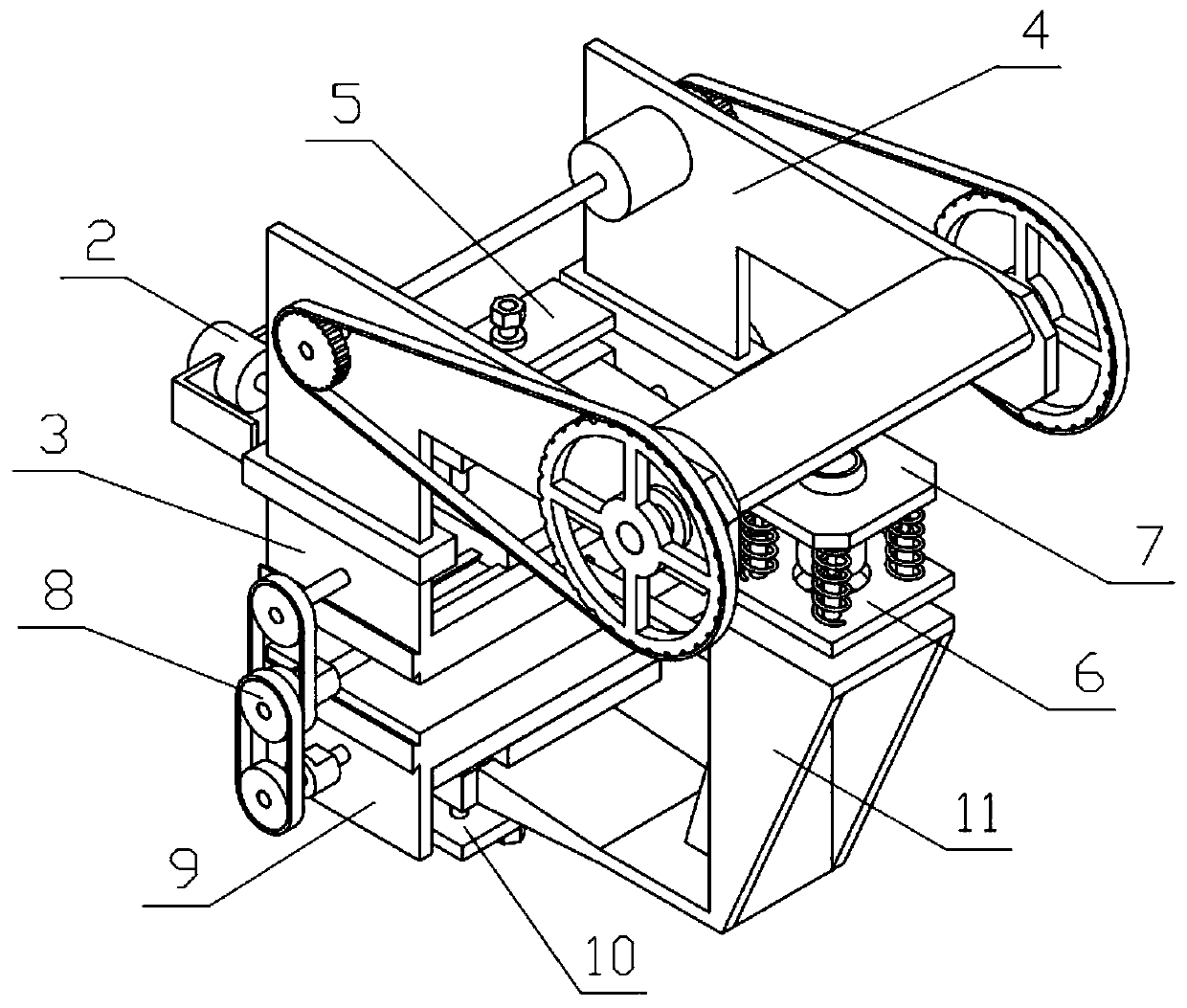

[0035] Combine below Figure 1-12Describe this embodiment, a five-axis stamping robot, including a device bracket 1, a moving motor I2, a sliding bracket I3, a stamping mechanism 4, a height bracket I5, a mold support plate 6, a stamping die 7, a moving mechanism 8, a sliding bracket II9, The height bracket II10 and the stamping chassis 11, the device bracket 1 is fixedly connected with the mobile motor I2, the device bracket 1 is slidably connected with the sliding bracket I3, and the sliding bracket I3 is connected to the output shaft of the mobile motor I2 through threads, and the sliding bracket The stamping mechanism 4 is fixedly connected to the Ⅰ3, the height bracket Ⅰ5 is slidably connected to the sliding bracket Ⅰ3, the mold support plate 6 is fixedly connected to the height bracket Ⅰ5, the stamping die 7 is connected to the mold support plate 6, the stamping die 7 and the mold support plate 6 is fixedly connected with a compression spring, the upper end of the stampi...

specific Embodiment approach 2

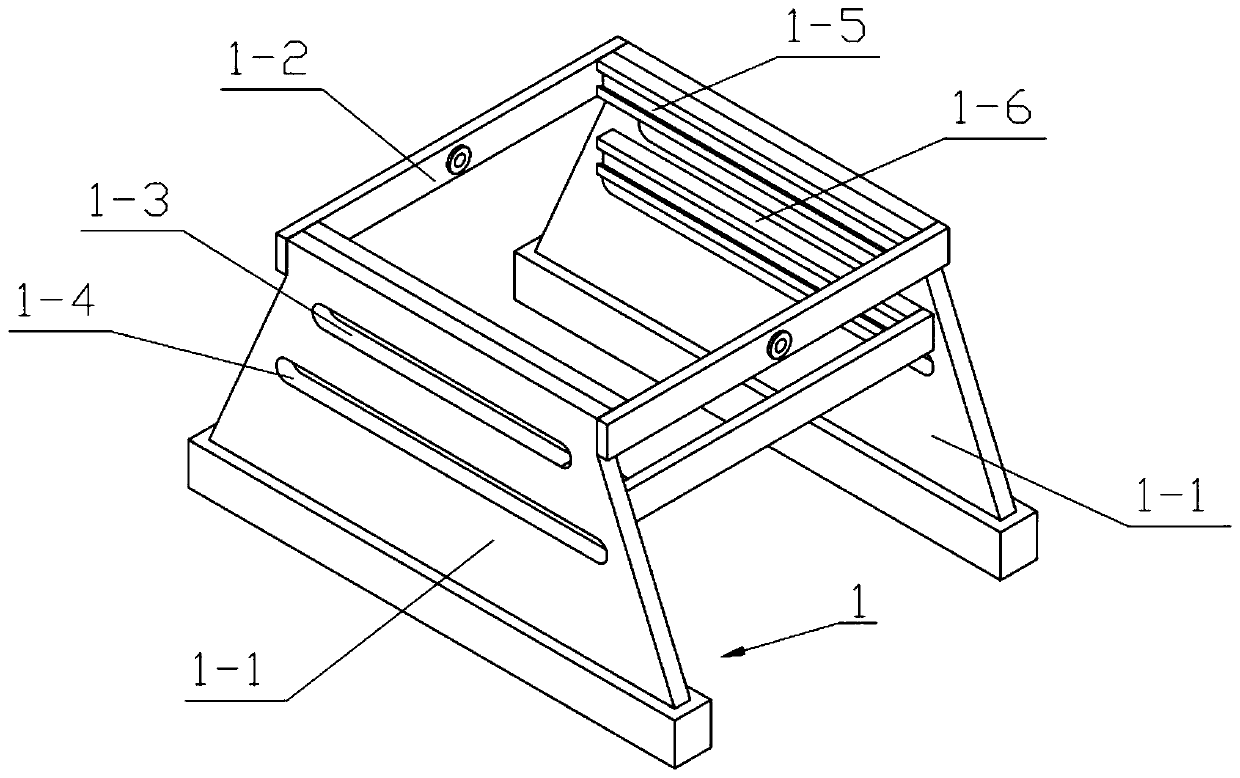

[0037] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the first embodiment, the device bracket 1 includes a support plate 1-1, a connecting plate 1-2, a sliding waist hole I1-3, a sliding waist hole II1-4, and a sliding track I1 -5 and sliding track II 1-6, two support plates 1-1 are provided, and a connecting plate 1-2 is fixedly connected in the middle of the two support plates 1-1, and a sliding track is provided on the two support plates 1-1. The waist hole I1-3 and the sliding waist hole II1-4 are fixedly connected with the sliding track I1-5 and the sliding track II1-6 on the inner sides of the two support plates 1-1.

specific Embodiment approach 3

[0039] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the second embodiment, the sliding bracket I3 includes a sliding bottom plate I3-1, a sliding track III3-2 and a side plate I3-3, and the sliding bottom plate I3-1 is slidably connected to two Between the sliding tracks Ⅰ1-5, the sliding bottom plate Ⅰ3-1 is fixedly connected with the sliding track Ⅲ3-2, both sides of the sliding bottom plate Ⅰ3-1 are fixedly connected with the side plates Ⅰ3-3, and the mobile motor Ⅰ2 is fixedly connected with the connecting plate 1 On -2, the sliding bottom plate I3-1 is connected to the output shaft of the mobile motor I2 through threads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com