Open-pit mine blasting technical method for avoiding large blocks in frozen layers

A technology of frozen layers and large blocks, applied in the field of mining engineering blasting, can solve the problems of large frozen blocks and poor blasting effects of frozen layers, and achieve the effect of ensuring the filling length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

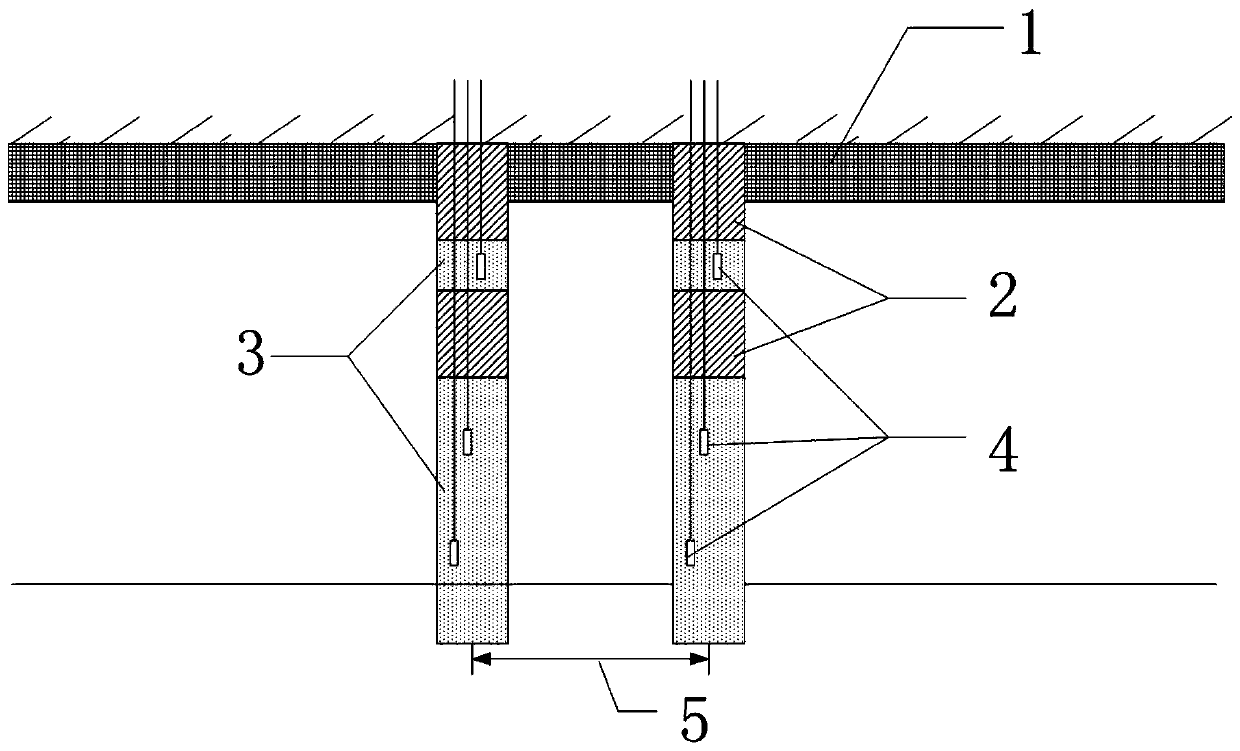

[0030] like figure 2 As shown, drilling is carried out on the frozen layer 1 with a thickness of about 2m. According to the actual terrain conditions, the azimuth is measured, and the holes are arranged in a triangle. The row spacing of the holes is different according to the lithology. The roller cone drilling rig drills blastholes on the blasting work platform with frozen layers;

[0031] Hole loading: According to the blast hole obtained by the drilling machine used, the hole diameter of the blast hole is 250mm, and the interval charge is used. First, the emulsion explosive 3 with a blast hole depth of 9 / 17 is continuously loaded into the blast hole, and then the blast hole is backfilled with a depth of 7. / 34 backfill gravel 2, after backfilling the gravel, install emulsion explosive 3 with a depth of 1 / 17 of the blast hole, and then backfill gravel 2 with a depth of 7 / 34 of the blast hole;

[0032] Detonation method: three detonators 4 are installed in each blast hole, ...

Embodiment 2

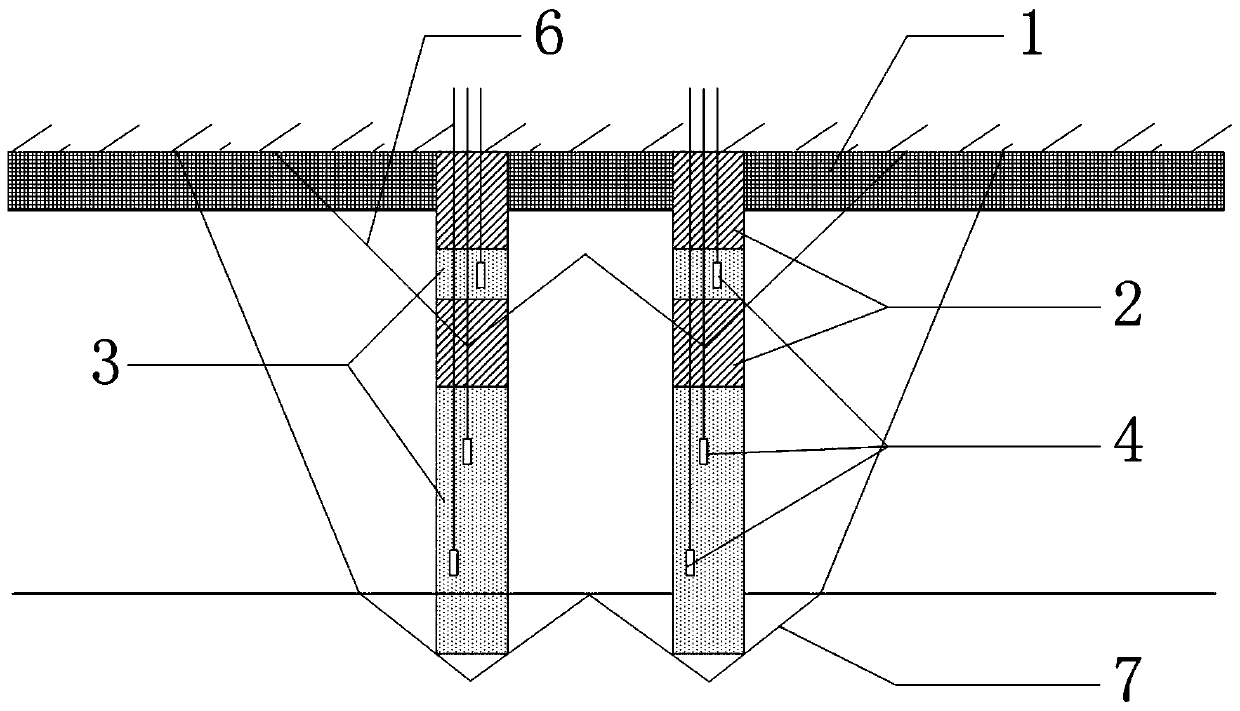

[0035] The depth of the blast hole in this embodiment is 17m, and the specific steps are as follows:

[0036] Step 1: Drilling: According to the actual terrain conditions, measure the azimuth, determine the hole position and hole row spacing, and use a 250mm-diameter roller cone drill to drill a blast hole on the blasting work platform with a frozen layer. The depth of the blast hole is 17m;

[0037] Step 2: Loading holes: According to the blast hole obtained by the drilling machine used, the hole diameter of the charge blast hole is 250mm, and the interval charge is used. First, the blast hole is continuously charged with 9m, and then backfilled with 3.5m of crushed stone. After that, charge 1m of powder, and then backfill 3.5m of crushed stone;

[0038] Step 3: Detonation method: each blast hole is equipped with three detonators, and the detonators are installed in the detonating bomb to increase the detonation energy and ensure that the explosives can be detonated. like ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com