Automatic PCB sorting system and method

An automatic sorting system and PCB board technology, applied in the field of PCB boards, can solve the problems of damaged products, low sorting efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

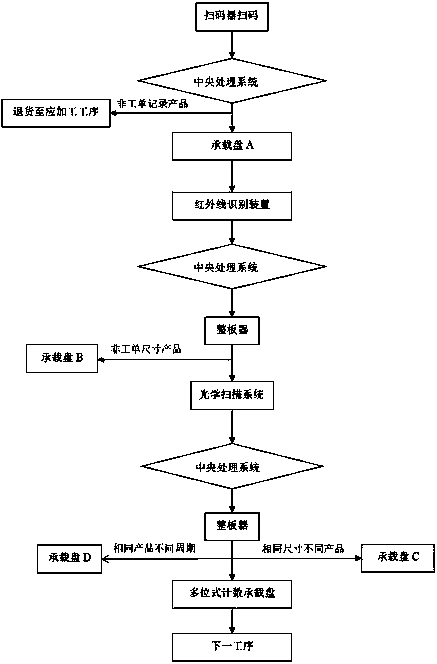

[0027] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0028] An automatic sorting system for PCB boards, including

[0029] Central processing system: used to identify the difference between PCB board products and preset product standards, control the work of the whole board machine, and control the parameter setting, operation mode setting, information storage and release of the automatic sorting system;

[0030] Infrared identification device: used to identify product size and provide product size information to the central processing system;

[0031] Transmission system: composed of multiple motors and conveyor belts for PCB board transmission;

[0032] Carrier tray: The carrier on which the PCB products are placed can be automatically lifted and lowered, and has a full-load warning function. The carrier tray includes carrier tray A, carrier tray B, carrier tray C, and carrier tray D;

[0033] Optical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com