Gas box type blowing wind pipe dust removing device

A technology of spraying blowpipes and dust collectors, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve problems such as poor self-cleaning effect, unfavorable maintenance and installation, and complex structure, so as to facilitate maintenance and improve The effect of flow and overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

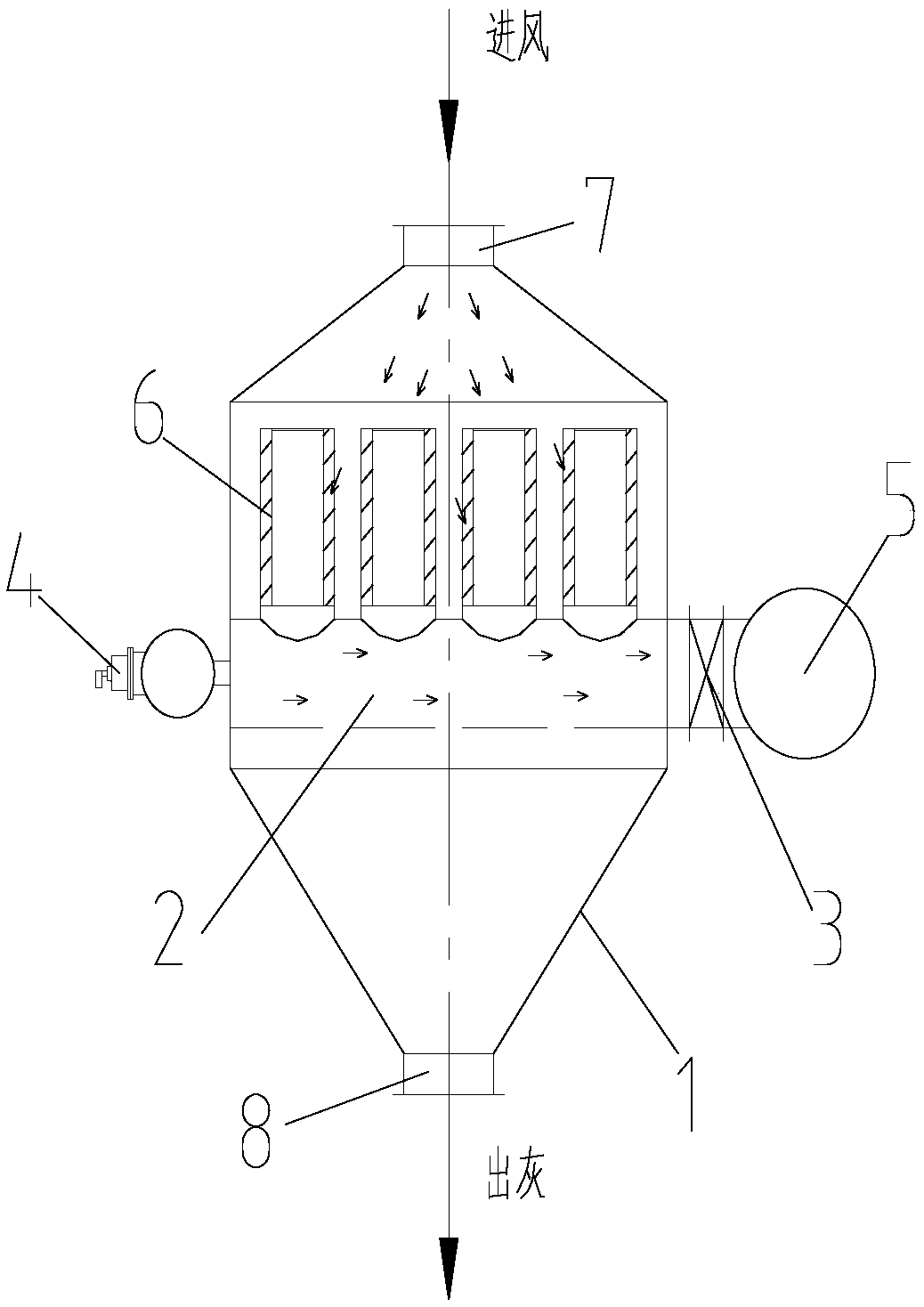

[0021] See attached figure 1 , figure 2 As shown, a kind of air box type blow pipe dust collector in the present embodiment comprises box body 1, and described box body 1 is made up of air inlet box body, filter box body and ash hopper distributed up and down, in the air inlet box The air inlet 7 is arranged on the body, and the ash outlet 8 is arranged below the ash hopper; a group of spray blow pipes 2 (the number of spray blow pipes in this embodiment is three) are arranged in the filter box, and each The upper end face of the blow pipe 2 described above is provided with several flange connections (there are four flange connections in the present embodiment), and a filter cartridge 6 can be vertically installed on each flange connection (if The flange interface is not equipped with a filter cartridge, which can be blocked by installing a cover plate); the two ends of the spray blowpipe 2 all extend to the outside of the casing 1, and each spray blowpipe 2 on the same side...

Embodiment 2

[0025] A kind of air box type blow pipe dust remover among the present embodiment, as image 3 As shown, its structure is substantially the same as that of Embodiment 1, except that a filter screen 10 is arranged below the blowing duct 2, and the edge of the filter screen 10 is fixedly installed on the box body 1.

[0026] Such as Figure 4 (a), Figure 4 A filter screen 10 shown in (b) has a corrugated structure. The wave crest of the filter screen 10 is located in the gap between the two spraying blow pipes 2, and the filter screen 10 in contact with the box body 1 is its wave peak or trough, and the trough of the filter screen 10 is provided with a drain. Dust can be blocked by filter screen 10 like this, avoids that the air-flow of ash outlet 8 place is excessive and influences the deposition of dust in the ash bucket that links to each other with ash outlet. Under normal circumstances, the ash outlet of the dust collector will be connected with the ash bucket for dust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com