Drum shearer electrical module detection test bed and detection method

A coal mining machine, mechanical and electrical technology, applied in the field of electric module detection test bench of drum shearer, can solve problems such as the inability to change the speed of the traction direction, the failure of the rocker arm to lift, and the failure of the remote control end station, etc., to improve troubleshooting effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

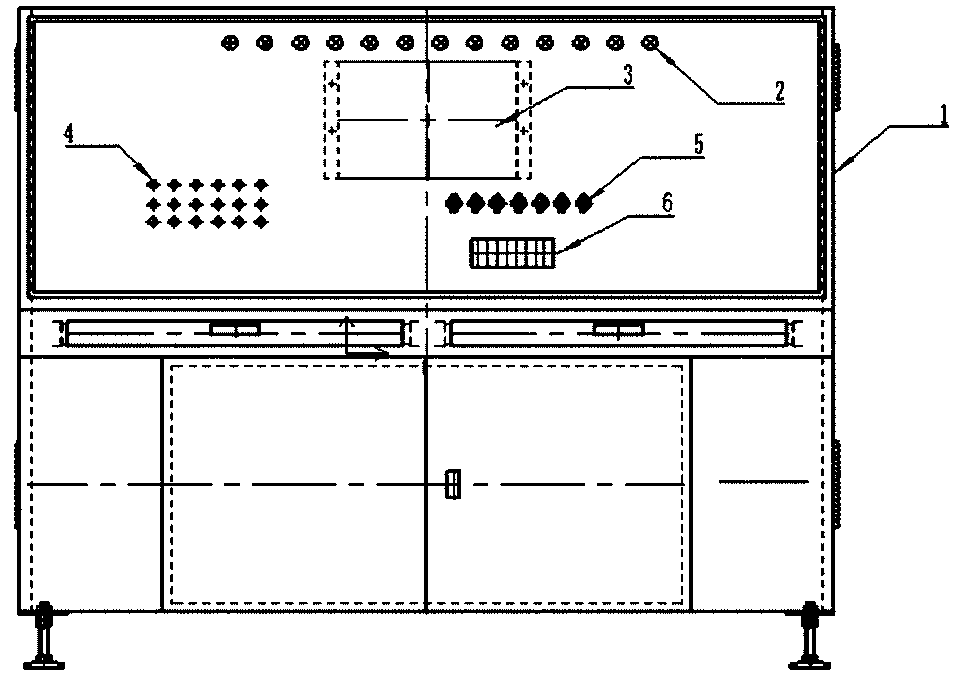

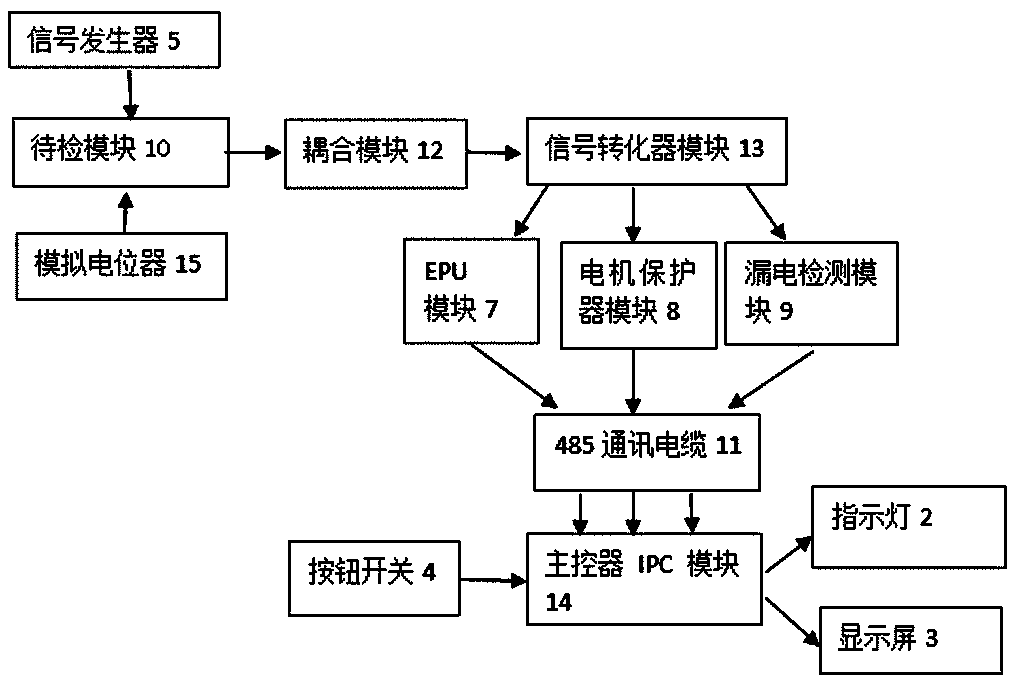

[0020] The electric module detection test bench of the drum shearer of the present invention includes a main control box and an electric detection module; the main control box includes an indicator light 2, a display screen 3, a button switch 4, a signal generator 5, an analog potentiometer 15, and a detection interface 6. The detection interface 6 includes an EPU module detection interface, a motor controller module detection interface, and a leakage detection module interface; the above-mentioned components are installed on the main control cabinet 1. The electrical detection module includes EPU module 7, motor protector module 8, leakage detection module 9, 485 communication cable 11, coupling module 12, signal converter module 13, and main controller IPC module 14; EPU module 7 includes current transformer and vacuum Contactor; Among them, the motor protector module 8 uses Delixi CDS9-ABC; the signal generator 5 uses SIN-C702, the analog potentiometer 15 uses 3590 series, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com