Continuous rolling mill vibration signal separation method based on sparse feature similarity

A vibration signal, sparse feature technology, applied to vibration measurement in solids, measurement vibration, measurement devices, etc., can solve algorithm failure, poor estimation accuracy and robustness, and can not meet the independence assumption of independent component analysis algorithm. and other problems to achieve the effect of improving accuracy and filtering out interference noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Vibration signals of 4-stand continuous rolling mills (including 4 continuous rolling mills) are collected by acceleration sensors, and a vibration signal separation method of continuous rolling mills based on sparse feature similarity of the present invention is applied to effectively separate the vibration signals.

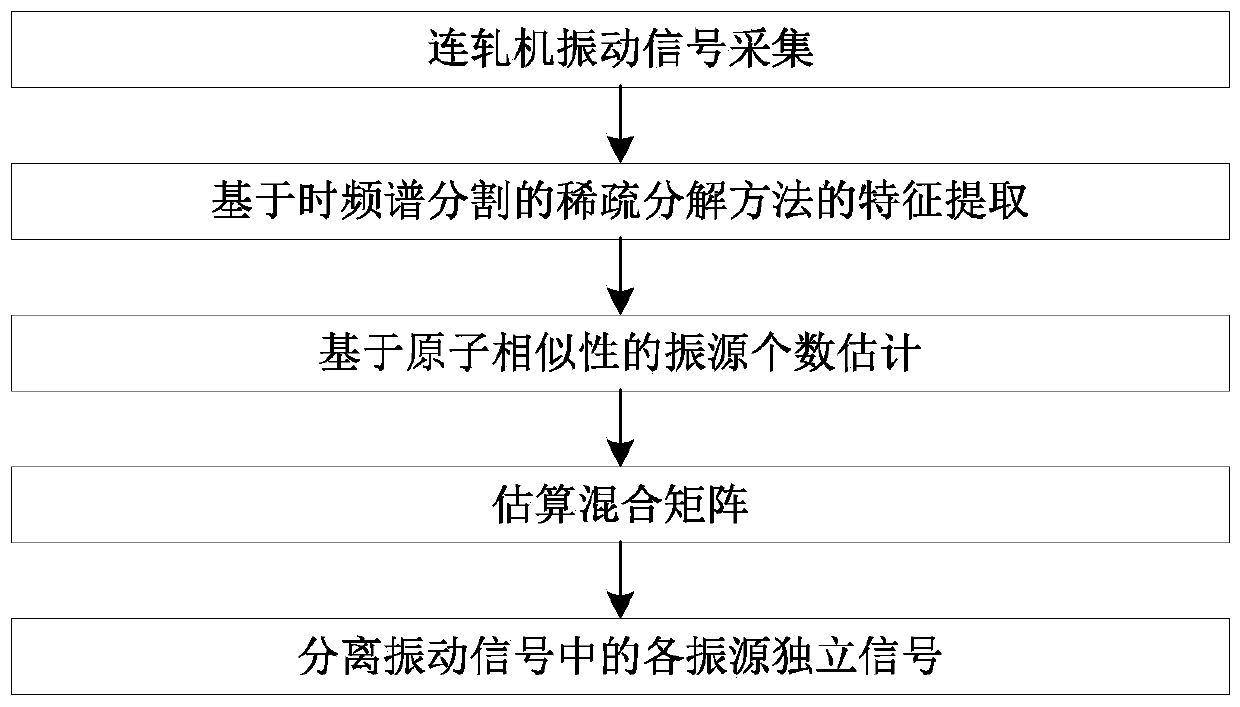

[0078] like figure 1 As shown, the specific method steps are as follows:

[0079] (1) Collect the vibration signal of the continuous rolling mill through the acceleration sensor:

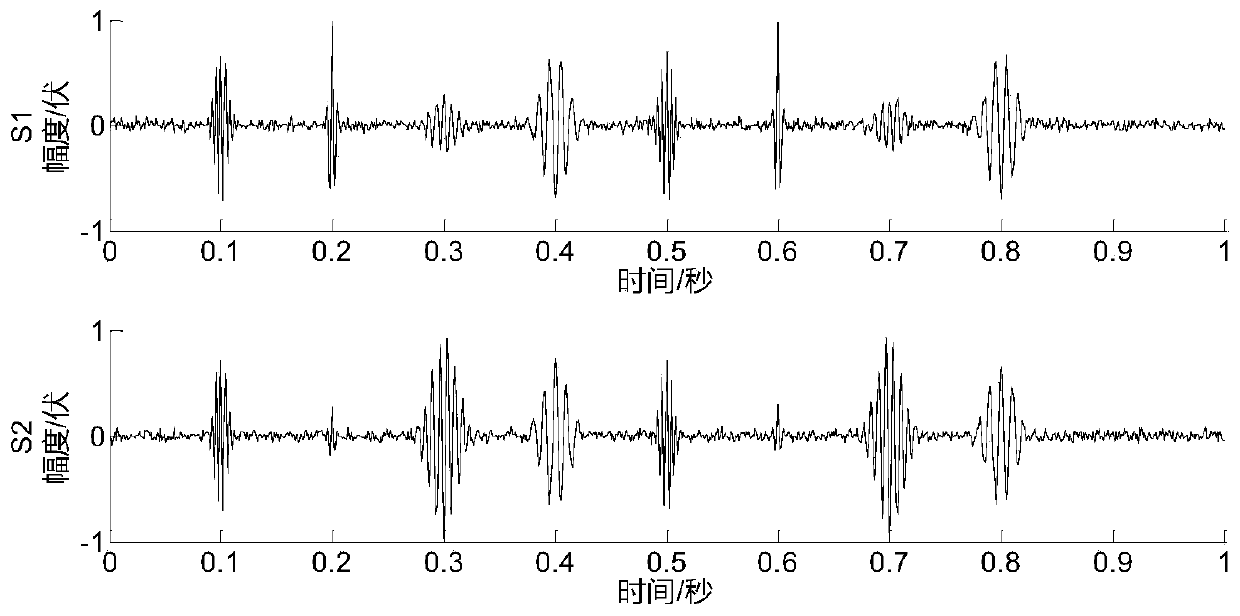

[0080] Acceleration sensors are respectively arranged on the lower work roll chocks (two observation points) of the two continuous rolling mills F1 and F2 in the continuous rolling unit to collect the vibration signals of each vibration source when the rolling mill rolls steel; figure 2 Shown are the observation signals of the two channels (two sets of observation signals) collected at the above two observation points respectively, where S 1 is the vibration signal collected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com