Prefabricated building periphery parapet body

A prefabricated and wall-mounted technology, which is applied to buildings, building components, and building structures, can solve problems such as high risk, high difficulty in the installation process, and heavy wall weight, achieving short construction periods and simple and convenient assembly processes , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

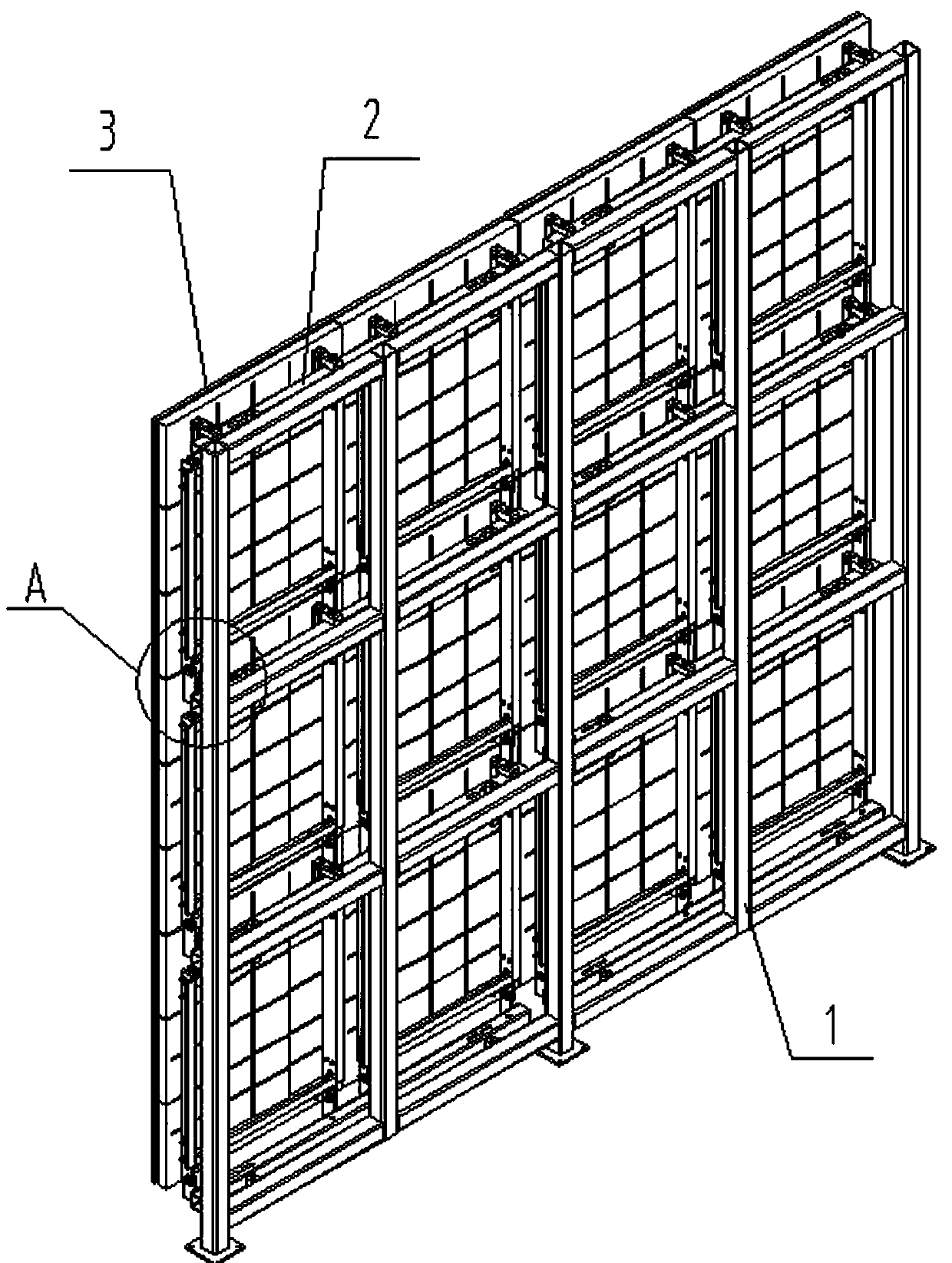

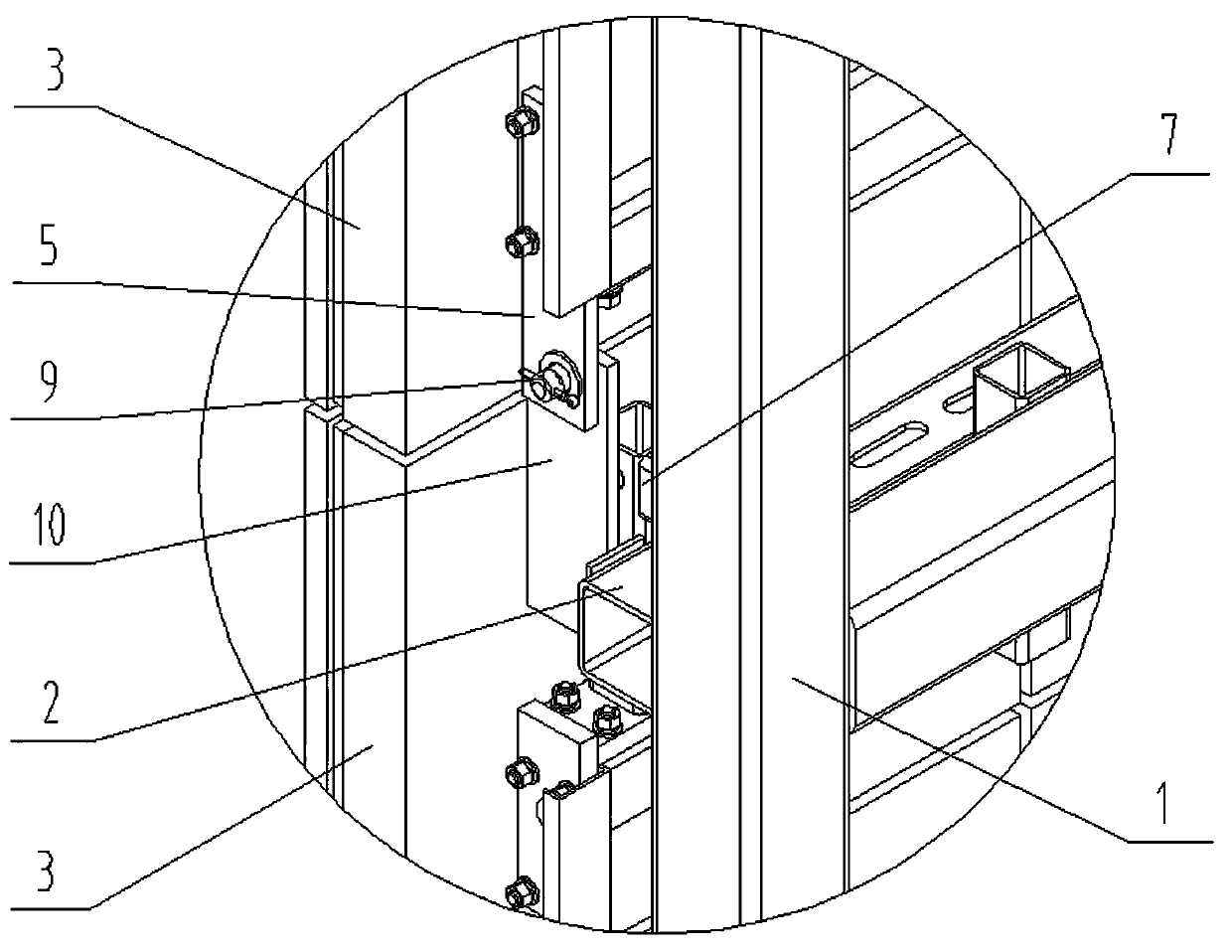

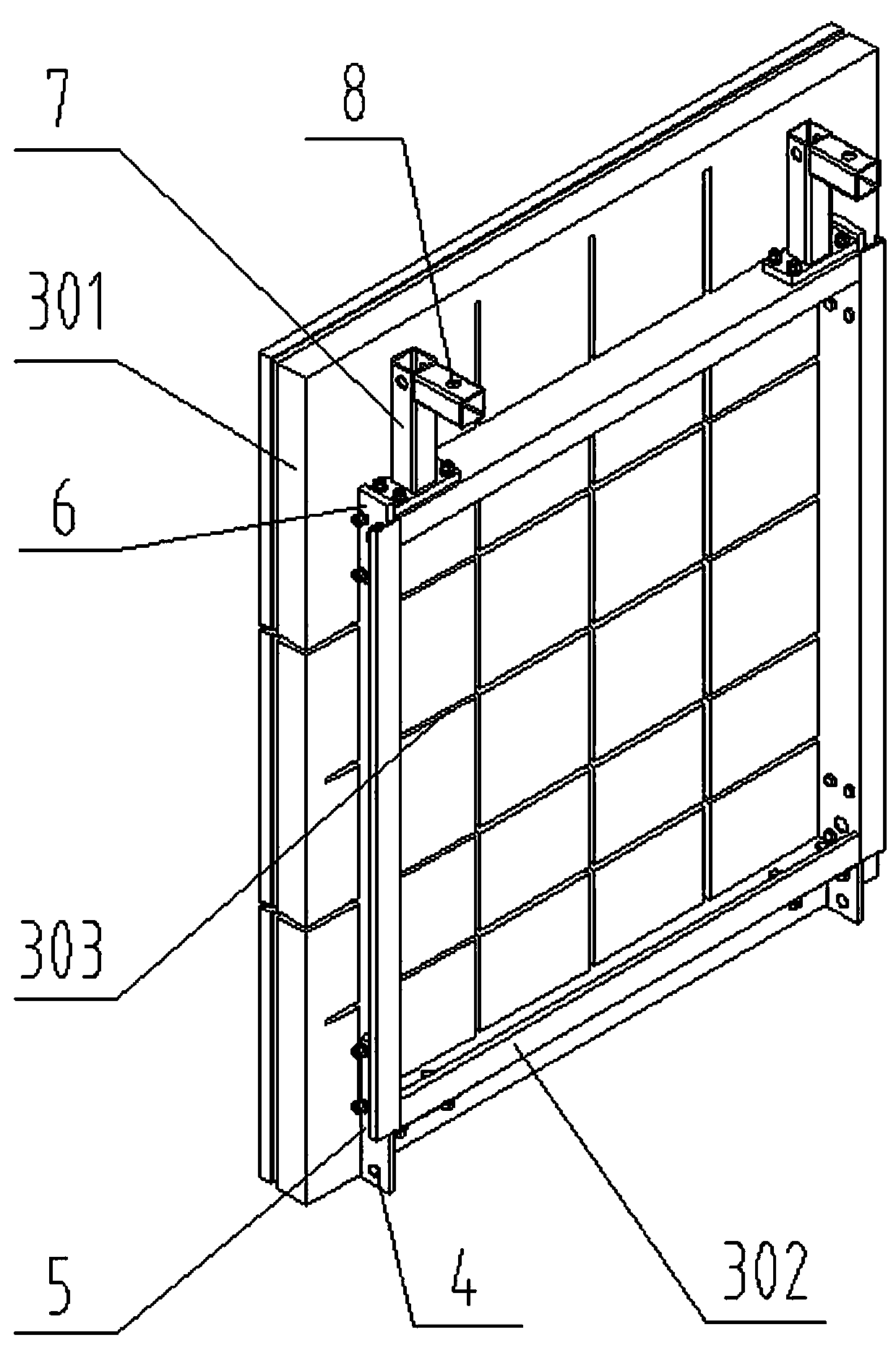

[0023] Such as figure 1 As shown, a prefabricated building enclosure wall of the present invention, a supporting member 1 and a plurality of composite walls 3 hung on the supporting member 1 through load-bearing balance beams 2 . The support member 1 is a frame structure, and is welded and fixed on the embedded part of the building or the joint beam of the steel structure building. figure 1 Two load-bearing balance beams 2 are fixed at intervals at the same height of the supporting member 1, and two composite walls 3 are mounted on any one of the load-bearing balance beams 2. It should be noted, figure 1 It is only an embodiment of the present invention. In the specific application of the present invention, the quantity of the load-bearing balance beam 2 and the composite wall 3 can be flexibly set according to the specifications of the building wall. The number of composite walls 3 located on the same load-bearing balance beam 2 can be one or two.

[0024] Such as image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com